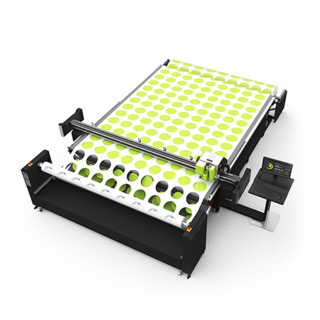

Esko Automated Board Feeding and Material Stacking Solution for Kongsberg Table

Three different models match the different Esko Kongsberg C and X series.

Pressure on digital finishing departments forces them to manage short production runs intelligently, eliminate material waste, and optimize equipment output. Typical finishing operations suffer because there are too many manual steps, and prioritizing jobs and optimized material handling is not always possible. Esko has learned that one of the most effective ways to increase productivity is not by marginally speeding up cutting, but by ensuring that cutting tools are always in operation; and not idle.

Esko’s new Esko Automated Board Feeding and Material Stacking Solution of high-capacity pallet-to-pallet sheet feeders and stackers can handle the widest range of rigid board substrates, up to 100 lbs. Three different models match the different Esko Kongsberg C and X series, handling boards as large as 5’x10’. They handle pallets of materials with multiple stacks at high speeds, can be accessed by a forklift and are indispensable for all applications that require medium to high run lengths of rigid materials.

i-BF board feeders increase productivity and reduce operator time when the Kongsberg tables are used for short-run production jobs.

The i-BF feeds corrugated, paper core boards and plastics quickly and accurately from a pallet with 16-second feed cycles in a continuous material flow. There are no delays loading boards to the table, so the table is utilized nearly 100%. The feeder offers great flexibility, as it can also be used in conjunction with a roll feeder for flexible materials without having to exchange the board feeder. i-BF board stackers have a robust vacuum system that can handle the entire board easily. It leaves a very cleanly stacked pallet. This means that nicking is not required to hold the waste materials to the printed piece. Once they are stacked on the pallet, stripping waste

from the printed piece is very easy—eliminating possible bottlenecks.