Technology Outlook Week

Be sure to sign up for our Technology Outlook Week Webinars at whattheythink.com/webinars. The Wide Format, Signage and Apparel Webinar will take place Thursday, May 20 at 1 p.m. ET, and will be presented by Richard Romano and Cary Sherburne. Here's a preview of some of the items we will discuss.

Wide Format and Signage

General trends in wide format and signage since our last Technology Outlook Week have been almost exclusively COVID and safety signage-related. They include:

- Policy Communication. As businesses and other venues reopen, signage communicating policies regarding mask wearing, social distancing, etc., has been required. Floor graphics/distancing dots have proliferated and new materials and overcoatings have helped improve the durability of these graphics.

- Vaccinations. Vax sites have required their own wayfinding and other related signage. As IRL events start to take place later this year, there will be demand for COVID-related signage at individual venues. Print businesses that have been waiting for their events- and travel-centered customers to ramp back up are going to have a very good 2021. It’s unclear what policies regarding proof of vaccination (or so-called “vaccination passports”) are going to be required, and while much consternation has arisen regarding potential governmental policy, the fact remains that it will be individual venues and/or events coordinators who will set specific requirements.

- Back to Work. As businesses bring their employees back from the work-at-home experiment, it’s also unknown what kinds of vaccination requirements they may set for employees. Regardless, signage will be required to communicate whatever policies emerge, which will likely (or should) be integrated into an office’s environmental graphics.

- Celebration Time! Last year at this time, we saw an emergence of celebratory lawn signage honoring graduates and other student achievements. As we write this in early April, we have started to see “Class of 2021” signs start to bloom on residential lawns. Whether these will be as in-demand as they were last year remains to be seen, but a sign shop or display graphics provider can make a nice chunk of change offering these kinds of signs; all it takes is one or two houses on a block to put one out and others in the neighborhood will often follow suit.

As for recent new technologies and product announcements, late 2020 and early 2021 may have been a little slow compared to some previous years, but that could just indicate a relative maturity of the wide-format equipment market. As we have been seeing, even pre-pandemic, there have not been too many major technological innovations in the wide-format equipment sphere. Major introductions have predominantly focused on filling in gaps in vendor portfolios. Flatbed printers have seen some tweaks to things like board feeding and vacuum tables, the goal being to complement improvements in print speed with faster on- and off-boarding. Across the board, speed improvements are top improvements.

Here are some quick hits of what the past six months or so have brought us.

Agfa has launched the Jeti Tauro H3300 UHS, a 3.3-meter LED hybrid aimed at the high end of the market. At speeds capable of up to 600 square meters per hour, it is the fastest unit in the Jeti Tauro series to date, or 30% faster than other Jeti Tauros.

Agfa Jeti Tauro H3300 UHS (bull sold separately).

Agfa Jeti Tauro H3300 UHS (bull sold separately).

Last September, Canon U.S.A. launched a new Arizona series of flatbed printers, the fifth-generation Arizona 2300 Series comprising the 49.2 x 98.4-inch 2300 GTF and the 121.3 x 98.4-inch 2300 XTF. The new Arizonas also debut FLOW technology, a novel approach to media handling featuring a different kind of vacuum table that eliminates the idea of “zones” and reduces or removes the need for masking or taping. FLOW uses a new airflow and vacuum system that lets users place media anywhere on the table surface without needing to worry about securing it in place.

Canon also updated its imagePROGRAF line of technical printers with the imagePROGRAF TZ-30000 Series.

Canon Arizona 2300 Series.

Canon Arizona 2300 Series.

Durst continues its “Pixel to Output” strategy with last year’s launch of the P5 350 High Speed Printing System, comprising the P5 350 High Speed printer, as well as the Durst “Automat,” a new full automation system, enhanced Durst software, a full LED ink portfolio and partnerships. The Durst Automate is a fully automated board feeding and stacking system that can manage up to two lanes, with different board sizes up to 3.5 m wide and 2.2 m long. Thanks to its sliding registration tables, access to the roll tool enables fast material change by a single operator.

Durst P5 350 High Speed Printing System.

Durst P5 350 High Speed Printing System.

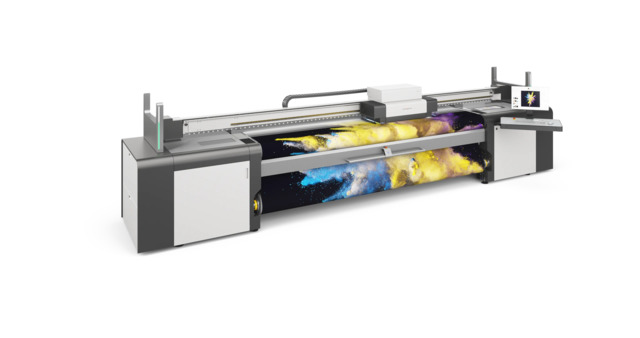

EFI has launched two new printers for the high-end, high-productivity soft signage market. The EFI COLORS 340 printer prints at up to 9,149 square feet per hour (in a four-color by four configuration) and for even higher-volume production environments, the EFI POWER 340 prints up to 16,835 square feet per hour. EFI also has some new units coming out later in 2021, including the Vutek XT—said to be the “fastest Vutek printer ever built”—and a 1.6 m single-pass display graphics printer that will print up to 1,000 boards per hour. Look for more information about those later in 2021.

Epson spent 2020 fleshing out its portfolio, and is now one of the few equipment manufacturers that offer products using all the major ink technologies—solvent, dye-sub, UV and latex (aka resin). First up was the new R-series of 64-inch roll-to-roll printers, the SureColor R5070PE and R5070L, based on a new aqueous resin ink that is looking to compete with latex in the signage/soft signage space. Then came the company’s first UV flatbed, the 4x8-foot 10-color SureColor V7000. The company has also been updating its SureColor T-Series wide-format multifunction printers for technical printing applications, most recently the 24-inch SureColor T3170M and 36-inch SureColor T5170M multifunction printers. Also keep an eye out for some news about a new textile printer.

Epson SureColor V7000.

Epson SureColor V7000.

HP updated its Latex line with four different 64-inch-wide units, the HP Latex 700, HP Latex 700W, HP Latex 800 and HP Latex 800W. “W” stands for “white” as these are the first Latex units in this class to utilize white ink.

Mimaki launched a new textile printer, the TS100-1600, an entry-level dye-sublimation transfer printer with high quality prints, and is part of Mimaki’s new 100 Series. Two other printers in the 100 Series are the UJV100-160 (UV-LED printer) and the JV100-160 (eco-solvent printer).

In September, Mutoh launched its own new dye-sub printer platform, the 64-inch XpertJet 1682WR. It uses Mutoh’s new DH21 Dye Sublimation ink and is available in both four-color (CMYK) and seven-color (CMYK, Lc,Lm,Lk,) configurations.

Roland DGA launched two new VersaUV printers, the 64-inch VersaUV LEC2-640 and 30-inch LEC2-330—next-generation UV printer/cutters designed for label, packaging, sign, display and interior décor production. Roland also launched TrafficWorks, a turnkey traffic sign printing solution based around the TrueVIS VG2 printer/cutters that offers a cost-effective, easy-to-use solution for producing traffic signage. Floor graphics are all the rage, and Roland has also introduced two new overlaminates, GuardLam Glossy Floor Overlaminate and GuardLam Embossed Floor Overlaminate, to its existing media offerings. The overlaminates both protect floor graphics from damage while also adding anti-slip properties.

The Roland VersaUV LEC2-640 and 30-inch LEC2-330.

The Roland VersaUV LEC2-640 and 30-inch LEC2-330.

At a March 2021 launch event, swissQprint introduced the Karibu S, where “S” stands for “speed” and is the high-speed version of its Karibu UV roll-to-roll printer, capable of up to 330 square meters per hour. Both the Karibu and the Karibu S are now capable of automatic double-sided printing. At the launch event, swissQprint also debuted a line of neon inks for its LED UV rollfed and flatbed units.

swissQprint Karibu S.

swissQprint Karibu S.

This is not intended to be a comprehensive list of all the product introductions, but should give you a good sense of where the manufacturers are taking their product lines.

Textiles and Apparel

At the core of developments in textiles and apparel is a re-examination of the global supply chains whose frailty and excesses were laid bare by the pandemic. COVID-19 has accelerated the sustainability agenda; and implementing these various initiatives across highly complex supply chains will take a great deal of dexterity and commitment—but there can be no going back. All sectors working within the fashion industry’s supply chain must now adapt their business models and sourcing routes to include circularity, sustainability and eco-friendly innovation.

Here are just a few of the topics we will discuss in the textiles portion of WhatTheyThink’s Technology Outlook:

- Fibers. From organic and preferred cotton, to naturally sustainable fibers and new technical fibers, hybrid plant-based synthetics offer refreshingly simple circularity and polarize a regeneration. The future of fabric sourcing just opened a new chapter for the textile industry. The switch from a synthetic petroleum-based fashion industry to a cellulose supply chain is only just beginning, but there is no time to waste.

- Improved Dyeing Processes. Pollution from textile dyeing is still rampant, especially in Asia, often reflected in changing colors of rivers and other water bodies as dye colors change from day to day. There are a number of initiatives underway to tackle this problem, from spray dyeing to programs such as Color On Demand from Ralph Lauren, with a goal of delivering the world’s first scalable zero wastewater cotton dyeing system.

- Sustainable Inks. Over the last year or two, the number of more sustainable inks for digital printing of fabrics has grown significantly. With improved runnability, ink cost per meter and, increasingly, the requirement for eco-friendly, certified and sustainable credentials, ink companies have brought to market new inks to service the growing digital textile printing market.

- Circular Economy. There are a number of ways the circular economy is affecting the fashion industry, and many of them are things that you and I, as consumers, can do to reduce the waste in the system. It means a move from a linear economy – take-make-dispose – to a circular economy—make-use-recycle. Resurgence in fashion rentals and upcycling also help propel this trend.

- Demand for On-Demand. On demand manufacturing of textiles and apparel is key to reducing the significant inventory risk that has made fashion a low-margin business for decades. While this includes digital printing of fabrics, it can also mean a more conscious approach to forecasting that can also use analog methods of production. The key is to get rid of the 30-30-30 rule—a third of fashion sold at full price, a third on the discount table and a third in landfill—and leverage that recaptured capitalization to restructure supply chains.

In addition, we’ll discuss new digital printing solutions that have entered the market in the last year and profile a couple of on-demand manufacturing initiatives that are poised to have a significant impact on the future sustainability of the industry.

“Sustainability is not just about the product going out the door," said Marci Kinter, PRINTING United’s VP of Government and Regulatory Affairs. "It’s how you are treating your employees [and suppliers]. Are you in compliance with all environmental, safety and health regulations, which is, in turn, treating your employees well? Do you have any analog equipment on site? Really looking at the entire footprint of what you do and taking that into account. Then you can develop that sustainable benchmark. It’s not enough to say that just because I’m digital, I’m more sustainable than the person down the road who is doing conventional screen print. Because you really have to look at the total facility, not digital as a standalone.”