DPInnovations: A Complete web2fabric Workflow Solution

Web-to-print is well established in the world of commercial printing, and web-to-fabric is now gaining steam in textiles, as the demand for shorter runs and faster turn times for customized and personalized textiles and apparel grows.

In the world of commercial print, the analog-to-digital transformation is well underway, with high-quality color digital printing having been available since the mid-1990s. Its growth was augmented by the availability of web-to-print solutions around the same time as the Internet began to enter mainstream mode. But with the ability to submit orders online—in quantities as low as one—comes the need to automate the order-to-delivery workflow in order to ensure profitability. For many commercial printing companies, web-to-print hand-in-hand with process automation has contributed to a near-lights-out production process that enables them to handle a larger number of shorter run jobs—in the hundreds or even thousands per day—quickly and profitably.

In the world of textiles and apparel, the analog-to-digital transformation is just getting underway, with an estimated 5% to 6% of all fabric printing worldwide printed digitally, up from an estimated 3% to 4% just a couple years ago. While this is a small percentage of overall production, adoption is being driven by the same factors as previous analog-to-digital transformations: shorter runs and faster turn times with no sacrifice in quality and keeping costs in line.

A barrier in previous transformations, however, and a factor here as well, is the need for an end-to-end workflow that enables near-lights-out production, with automation from design through production and shipping. It is simply not affordable to throw more people at the problem, a solution that is both costly and error-prone. Rather, businesses that want to truly capitalize on the digital textile printing opportunity must adopt an end-to-end approach.

That’s where companies like DPInnovations come in. The company offers a complete web2fabric workflow solution that includes:

- Integration with an ecommerce solution such as Shopify or Magento;

- An online product configurator and visualizer to make the catalog creation process more efficient; and,

- Automation support for digital textile printer front-ends (RIPs) from a variety of manufacturers.

We recently spoke with DPInnovations’ founder Steve Smith, who has a long history in software for textiles. After leaving college in the UK, he worked for Textile Computer Systems, providing solutions for carpet, woven fabric, and printed fabric. DPInnovations was founded in 2008 in South Carolina, and offered RIP software to drive inkjet printers, color management solutions, and separation and engraving software for printed textiles. “Over the following years, as the U.S. printed textile industry was decimated,” Smith says, “we began focusing exclusively on digital technologies. We were the first provider to Spoonflower, as an example.”

While DPInnovations can provide the framework for a digital microfactory, Smith points out that there are many ways to approach the business. Organizations must first determine what business model they want to adopt—what they are going to print and for whom. “Once you have decided that, the next step is to acquire a suitable printer for those needs and make sure you have a way to get the work to the printer and out the door efficiently.”

He also points out that in the digital world, it is critical to have a strategy to drive visitors to your website. “You can’t be successful simply with organic growth,” he says. “You have to invest in marketing your site, search engine optimization (SEO), social media, etc. By working with someone who is skilled in SEO, you can create a plan—determine how much you want to spend per month, how many visitors you want to achieve, figure an average conversion rate and order size. This will help you establish what the revenue target should be. As a small business, this is pretty affordable. If you want to go after bigger companies, it can add up to thousands of dollars per month. This is why it is important to think through your strategy and get the right resources on board to implement that strategy. All of this up-front work will also help you determine which equipment best fits your needs. And you’ll want to have a good upgrade strategy in place to accommodate your needs as your business grows.”

Over the last two years, DPInnovations has put more than 20 installations in place, each customized to the specific needs of the customer. While most customers have DPInnovations under NDA, Smith reports that they are producing such things as high-quality silk scarves, high-end couture clothing, home furnishings and accessories, and more. “It’s very diverse,” he says. “There is no one formula that everyone uses.”

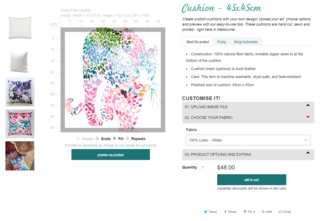

The company plans to continue introducing additional functionality. “The next thing we will be introducing is a mass market app for Shopify. We strongly believe it is important to use established ecommerce solutions, rather than developing your own, and our experience indicates that Shopify is one of the easiest to implement and very affordable. For us, it’s a plug-and-play solution within our workflow infrastructure. The app we will be introducing enables product visualization. You install it on your store and you have access to blank scenes for products. A small line of code installed on the web site will put the design into a scene you select and return it to the web site. If you were selling 100 different cushion designs, as an example, you would have to make the cushions, photograph them and post the images. With this app, you supply the blank cushion image and the 100 designs are automatically applied. You can have all 100 in your online inventory in a matter of hours.”

Smith calls the imaging process 2.5D. “It’s not quite 3D,” he says, “but you do have a perception of depth. It’s so easy to create and upload the images that you can easily have two or three different angles of view for each product. As the cost of true 3D comes down, we’ll look at implementing that as well.” The app is expected to be available at the end of 2018.