Executive Q&A

Kornit Digital showed a 118% year-over-year revenue increase for the second quarter of 2021. The company also has shifted its strategy a bit and made a couple of acquisitions that reflect this shift. In this Executive Q&A, Chief Marketing Officer Omer Kulka shares insight about Kornit’s strategic focus and the state of the industry at large.

Printing News: Congratulations on a great second quarter! You serve both the Direct to Garment (DTG) and Direct to Fabric (DTF) markets. How are sales allocated between the two?

Omer Kulka: We have had tremendous growth, that’s the bottom line, across all segments. DTG is still leading, by far, but we do see a lot happening in DTF. The promise of DTF is that it is a far bigger market because of the broad array of applications, markets and verticals. But there is a lot of work to be done for that to really become an alternative.

PN: For direct-to-fabric, it would seem that the finishing process for many home décor products would be easier than for apparel in terms of cut and sew.

OK: To be honest, we are not looking at the market like that anymore. During the second half of last year, we saw a fundamental shift in the industry. Everyone was affected by the huge pandemic-driven changes, of course. But another layer of understanding arose about how that relates to our industry, our market and our ecosystem. We understood that we really need to transform the industry to on-demand, sustainable production, and it doesn’t really matter whether it is DTG or DTF; it doesn’t matter how it is done. The drivers for change are coming from consumers. And consumers don’t care whether it was printed and then cut and sewn; or was cut and sewn and then printed directly on to the garment. When we start looking at the business that way, top down instead of bottom up, the story becomes more cohesive. On-demand fashion, which includes home décor, is our mission.

PN: Interesting that you include both home décor and apparel together in that way.

OK: We coined the term FashionX, which includes home décor, as it is any means of self-expression on textile, regardless of whether it is displayed in your house or on your body. It’s about you as a consumer and how fashion puts out there: who you are and what you believe in and what you want people to see. COVID also blurred those lines because everyone is at home on Zoom and video. On the one hand, everything is remote. On the other hand, everybody is inviting us into their homes. We also talk about Smart Textiles, not so much in terms of the typical way wearables are thought of, like you have a built-in computer on your shirt, but adding other types of functionality to the textiles through digital textile printing.

PN: Talk a little more about how this shift in the way you view the market and your business affects your overall market approach.

OK: For many years, we looked at the market trends as our friends. As a management team, we built the company so that when those trends – sustainability, personal expression, on-demand manufacturing – kept rolling, we surfed those waves, and we were happy. But we now understand not only that we can, but we actually have an imperative to play a much bigger role and proactively help drive the industry to transform, to accelerate that transformation. Instead of positioning ourselves in the best way possible to enjoy the trends, we have become more proactive. This helped us realize the need to expand our position in the market. So now we are extending horizontally on the production floor beyond the print room; and vertically, not only staying on the production floor but going all the way to the end consumer, and all the way down to logistics, blanks and textile providers; the entire ecosystem to enable and accelerate the on-demand and sustainable manufacture of fashion and home décor. We are starting to imagine the future production for our printed textiles, what the microfactories will look like, urban production, how to produce sustainably in urban areas - so far beyond our traditional core.

PN: To that end, you’ve done a couple of acquisitions recently. Tell us about how that fits with this strategy shift.

OK: Our acquisition of Custom Gateway allowed us to expand vertically, all the way to the end consumer. Voxel8 is more of a horizontal expansion that allows us to extend phases of production well beyond what we are capable of today.

PN: Let’s talk a little more about Voxel8, the most recent acquisition, and how it fits into the picture.

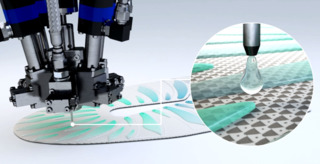

OK: With Voxel8, we identified a very unique technology, but the key was understanding how to merge that technology and capability with our existing capabilities and those on our technology roadmap. We understood we could begin to create things that don’t exist right now. We can enable the execution of our vision of on-demand sustainable manufacturing, not only in this vertical or that category, but for more and more categories. It is a true technological acquisition that allows us to enable transformation of additional categories right now from analog to digital. Instead of producing to inventory, which has a lack of sustainability, we can help move these categories to a more sustainable on-demand model.

PN: Can you be more specific about those capabilities?

OK: It enables new capabilities in both decoration and functionality. It opens up a lot more opportunities for us to offer decorative applications like metallic inks when added to our core technology. On the functional side, it opens up multiple opportunities such as reflective materials, which have larger particles and are difficult to inject through inkjet printheads. Here you have a different way of applying materials to a textile and it’s easier to do. It could also apply conductive materials.

PN: So are you looking at this as post-print treatments?

OK: It’s not necessarily a post-print function. Some applications may still be pre- or post-print, but our goal is to integrate it right into our current printing technology to provide more freedom in the design and production process. We’ve already done some of that with our current technology, with the launch of MAX which enables printing layers on top of the fabric to create 3D effects that can be either functional or decorative.

PN: Anything else Voxel8 brings to the table?

OK: A really unique capability of the Voxel8 technology is the ability to change the characteristics of the material they deposit on the fly. That means we can deposit a material that has different characteristics, in different places on the fabric - in the same process. A simple example is if I want a line of support, I can actually deposit some material across the fabric that will vary from super flexible to super hard. And the change can be gradual, so one area can provide support and then the same material becomes protective somewhere else, like on a shoe where you want the sides to be flexible and the heel area to be more rigid. When you integrate these capabilities into our system, we have a lot more levers to play with. The scope of possibility is pretty much unlimited. Activewear is another good example where you might want different levels of support in different areas. On top of that, we could also add a layer of therapeutic functionality. That’s what we mean when we talk about Smart Textiles. When it is produced on demand, it is not generically functional but can be customized depending on the needs of each individual piece.

PN: Let’s talk a little about the market as a whole. We hear a lot of different numbers in terms of the penetration of digital textile printing and the percent of the total printed fabric market that represents. What’s your take?

OK: We believe it ranges from 5% to 7% of the total. Digital textile printing grew to 3% of the total printed fabric market fairly quickly, and then from 3% to 5%. But it has plateaued over the last few years. I think that it reached a certain point of equilibrium. But also consider that the way we measure digital printing on textiles right now is about replacing a very specific part of the entire supply chain, a single link, replacing analog printing with digital. In these times, we need to do things that are transformative and not merely incremental. It’s not really about calculating how many digital printers you need to replace one rotary printer. That’s pure replacement. We don’t think that way at all. It’s not about replacing the way we do things today. It’s about enabling completely new ways of doing things, for both production and the business model. Let’s say you print to inventory in Pakistan and you ship it to the U.S. and there is a time span of six months from when it was designed and when it will be sold, and you also have a minimum order quantity to make it worthwhile for you from a pricing perspective. You inherently introduce a 30% overproduction into the model. That doesn’t fit today’s world, and the pandemic really exposed this.

PN: Plus, as the pandemic highlighted, things can occur that dramatically change demand so your products you designed six months ago don’t fit today’s market.

OK: Exactly. Consumers might be saying, "I wear yoga pants to work; I don’t need that suit anymore." The other change that needs to happen is how brands do their buying. Most buyers are compensated on how effectively they reduce cost per unit. They don’t really care if 50% of it is never sold. But another thing that COVID changed is getting the buy side and supply side at the same table with the same issues. Everything shut down all at once, and now everyone had the same enemy, the same problem. The solution is a more nimble supply chain, and that requires an increase in on-demand manufacturing capabilities. For the industry, it is not only that we can do that or should do that, but we are realizing that we have to do that. It is an imperative. It’s not about another business opportunity; it’s bigger than that. Running a business right now that only cares about dollar currency and not environmental currency, for me it’s not a viable approach.

PN: There are many challenges ahead, but overall, how do you feel about where the industry is going?

OK: I’m super optimistic about where the industry is going. The supply chain is going to change. Things are moving a lot faster today. Today we can begin to imagine a world where supply chains are different and more sustainable. And that’s what we are trying to enable as we work towards helping to accelerate industry transformation.