Printing Direct to Magnet on PrintMagnetVinyl is a Profitable Process

Master Magnetics, Inc. (The Magnet Source) is featuring wide-format printing directly to flexible magnetic material at SGIA, booth 1022.

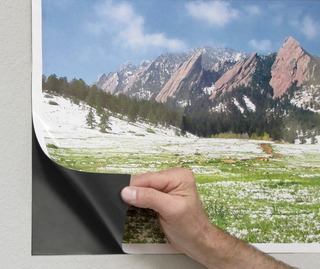

Master Magnetics, Inc. (The Magnet Source) is featuring wide-format printing directly to flexible magnetic material at SGIA, booth 1022. PrintMagnetVinyl, available in up to 40” widths, allows for high-resolution printing directly on flexible magnetic material with solvent, eco-solvent, UV and latex ink systems. PrintMagnetVinyl has been approved for HP latex printers as part of the HP Registered Latex Developer program.

PrintMagnetVinyl saves time and money printing direct to magnet instead of printing on a substrate (vinyl or paper, etc.) and then laminating it to the flexible magnetic sheeting. Another traditional method has been to print on non-magnetized magnetic material, and then magnetize it, also a more time-consuming, two-step process. Printing direct to the magnet is a more efficient and profitable process. New business opportunities that flexible magnetic sheeting provides include a variety of indoor and outdoor applications such as POP displays, signage, message boards, and promotional items such as magnetic business cards, menus, calendars, sports schedules and vehicle graphics.

FlexIRON Magnetically Receptive Sheeting

FlexlRON magnetically receptive sheeting is another component of Master Magnetics’ graphics system. FlexIRON, available up to 48” width, allows magnets to be used on any non-metallic surface, such as drywall, wood, concrete, or plastic. It is flexible iron sheeting, available with an adhesive backing and a printable vinyl surface.

FlexIRON can be used as the base layer for signs, photos and graphics printed on PrintMagnetVinyl, or it can be the top graphic layer, using the PrintMagnetVinyl with an adhesive backing as the base. This provides a useful option for sign shops that are not able to run magnetic material through their printer due to metal parts that cannot be covered or are internal.

Either option provides a multitude of magnetic solutions for graphics displays of all sizes ranging from menu boards and bank signs to designing the full-wall mural graphics required in retail environments. The simplicity of the system combined with high-resolution, photo quality printing surfaces and comparatively low costs, make Master Magnetics’ combination of FlexIRON and PrintMagnetVinyl a versatile and valuable graphics system.

Overcoming printing obstacles

A common reason cited by printers for resistance to printing on magnet is the concern for running magnetic material through their printer. A common problem may be if the platen is metal, the smooth and even flow of the magnet being fed into the printer would be restricted. This is easily overcome by covering the platen with styrene, chip board, vinyl or duct tape, or anything to create an air gap between the metal platen and magnet.

Other issues, such as print head height adjustment, ink saturation, or other metal parts of the printer that the magnet will come in contact with, could be answered by your printer manufacturer and referring to the printer’s profiles. “Everything you run through a printer requires a unique set-up for optimal performance and quality, and magnet is no different,” said Ralph Terramagra, Mutoh Eastern Regional Sales Manager. “The platen and post heater on most Mutoh printers are made of aluminum so they will not cause a problem with the magnet. There is a steel piece across the back where the media feeds in that will need to be covered as explained earlier. Basically, if you keep the magnet from sticking to metal it is really not much different than printing on vinyl. That being said, remember it is much thicker so keep your head height in a higher position, and it is also heavier so your print feed will need to be adjusted,” explained Terramagra.

Compatibility

Master Magnetics has partnered with major printer manufacturers to test their flexible magnetic sheeting. Testing for compatibility and quality has been completed with many international printer manufacturers including Mutoh, HP, EFI / Vutek, Epson, Gerber Scientific Products, Mimaki, Integra/Grapo, SII – Seiko Instruments USA, Canon (PrintMagnet with paper topcoat), Océ, FujiFilm, Jetrix, Screen, Polytype and is in process with other well-known brands.

Master Magnetic’s PrintMagnetVinyl sheeting is available in thicknesses of .015”, .020” and .030”, widths of 12”, 24”, 30” and 40”, standard roll lengths of 10 and 25 ft. and can be cut, slit or die cut for customized widths and lengths.

For aqueous ink printers, Master Magnetics also offers PrintMagnet flexible magnetic sheeting with a paper topcoat instead of vinyl that allows for printing directly to the magnet.