Technology Update Week—Wide Format, Signage, and Apparel

I have written often over the past six years or so about the growth of dynamic digital signage (DDS), signage that in its initial incarnation used LCD screens to display video, Power-Point-like slides, and even piped-in data sources such as stock tickers

Back in April, I received a press release from SNA Displays, a manufacturer of LED signage systems, whom I have profiled on a few occasions. They had recently provided 10 LED displays as part of the Albany (N.Y.) Airport’s major renovation project. That’s my home airport and since I usually fly Southwest, I looked at the accompanying image rather forlornly:

Someday, I hope to see the new signage in person—should we be allowed to go to events again.

I have written often over the past six years or so about the growth of dynamic digital signage (DDS), signage that in its initial incarnation used LCD screens to display video, Power-Point-like slides, and even piped-in data sources such as stock tickers and weather updates. DDS has been penetrating into all kinds of locations, from hotel lobbies, to restaurants and bars, to hospitals and doctors’ offices, to general business reception areas and, yes, to airports. In recent years, as the Albany Airport example indicates, DDS is still a high-growth form of signage, but LED displays are starting to replace LCD, especially as the quality of the display (i.e., the “resolution”) gets better, and almost photorealistic imagery and animations can be piped to the displays.

New Dimensions

Another growth area in the signage world is 3D printing. Recent WhatTheyThink and Printing News surveys (see for example, the Top 100 Small Printers feature starting on page 8) have found that 3D printing has yet to appear on print businesses’ radars, but they have a place in wide-format and signage providers in that they can be used to create channel letters, among other things, which remain the most common elements of signage. New systems from Massivit and Mimaki provide a range of 3D printing options, from entry-level to high-end 3D print production for retail applications and even the fast-growing collectibles and gaming markets. (See the feature on Mimaki’s latest 3D printing systems on page 44.)

Wide-Format Printing

On the wide-format printing front, we have reached a kind of maturity in the market; we have not seen too many truly revolutionary products. Rather, new product introductions have been more evolutionary, boosting speed, productivity, automation and filling in gaps in vendors’ portfolios to offer entry-level or mid-range options. Let’s run through some recent introductions.

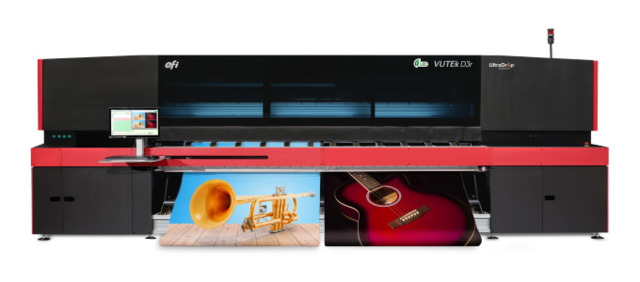

EFI has launched a new mid-range roll-to-roll printer line, the VUTEk D3r and D5r LED inkjet printers, younger brethren to the VUTEk 3r+ and 5r+ units. The D3r and D5r printers, are at 3.5- and 5.2-meters wide respectively. The D3r, which debuted last January at EFI Connect, when we still had events, prints up to 2,196 square feet per hour, and the D5r at up to 2,626 square feet per hour. The new printers also offer white and clear inks, as well as a “Museum” print mode. The new models are designed to produce high-end signage, décor, outdoor graphics and other applications.

EFI’s newest product is the 3.2-meter EFI Pro 32r+ wide-format roll-to-roll LED printer, designed to be an economical, all-in-one, production-level printer, capable of speeds of up to 2,756 square feet per hour in four-color plus optional white or clear ink. It offers a variety of white print modes, and can print up to five layers of white including an opaque white layer, selective or spot white, or a white layer that can serve as a light diffuser in backlit applications.

The EFI VUTEk D3r.

This spring, Epson refreshed its SureColor T series of printers designed for technical printing and the AES (architecture/engineering/construction) market. Two years ago, Epson debuted a desktop 24-inch wide-format technical printer, the SureColor T3170/T3170x. The new SureColor T2170 complements the earlier model as a more entry-level device, with a price point about $200 less than the earlier desktop unit. For somewhat larger workgroups, the new 24-inch SureColor T3475 and 36-inch SureColor T5475 replace the SureColor T3470 and SureColor T5470. These new models also use Epson’s new high-capacity 700mL cartridges.

Epson SureColor T2170.

Last year, Fujifilm launched the latest in its Acuity series, the Acuity Ultra, a 5-meter superwide UV press that supports printing multiple rolls simultaneously. It prints on a wide variety of materials with its low-density Uvijet inks and can thus print things as diverse as billboards, backlit signage, indoor displays, trade show graphics, POP signage, high-value graphic art, backlit displays, interior décor and wall coverings, outdoor displays, outdoor signage and more. The Acuity Ultra is also available in a 3.2-meter version.

The Fujifilm Acuity Ultra.

HP has expanded its Latex R series—R standing for “rigid,” as the R series is a hybrid flatbed/rollfed system. The three models in the Latex R series include the brand new entry-level HP Latex R1000, which is by default a sheetfed unit with a rollfed option available; the HP Latex R1000 Plus which comes in a sheetfed or rollfed configuration; and the high-productivity HP Latex R2000 Plus. The R1000 and R1000 Plus support media up to 64 inches wide, the R2000 Plus media up to 98 inches wide. The HP Latex series now offers white ink, which had long been absent from HP’s Latex line and is a welcome addition. Media loading and handling have been improved and those as well as software upgrades are available to existing Latex R Series customers.

HP Latex R1000.

LogoJet celebrated its 15th anniversary with the announcement of its UVx40R PLUS, an enhanced edition of UVx40R tabletop UV flatbed printer, for the printing and decoration of three-dimensional items. The enhanced machine features a longer print bed to accommodate larger media sizes—18 x 24 inches, offering 33% more print area than the earlier model.

Roland continues to tweak its benchtop flatbed UV printers to tap into the growing tchotchke-printing market. The new VersaUV LEF2-300D is a UV unit that allows direct printing (and simulated embossing) on three-dimensional items such as smartphone cases, awards, souvenirs, giftware, leather goods, electronic devices and more. The new unit is larger than previous units in the series, supporting a height of up to 7.87 inches which is twice that of previous LEF2 models.

The Roland VersaUV LEF2-300D.

Last Fall, in the Before Times, Roland launched the IU-1000F high-volume UV flatbed printer, which prints on up to 4 x 8-foot rigid boards weighing up to 99 pounds at an average speed of ~35 boards per hour in “Draft” mode and 10 boards per hour in “Quality” mode. The new flatbed uses CMYK + Gloss and White GREENGUARD Gold-certified UV inks, with a Primer ink option to promote greater adhesion on fussy substrates.

The Roland IU-1000F.

In 2019, North America saw the migration of the Karibu—the swissQprint Karibu that is, the company’s 3.4-meter UV rollfed printer which was launched at PRINTING United last October. The Karibu offers nine freely configurable channels (CMYK + 5 colors).

Textiles and Apparel

Perhaps the biggest development in textile and apparel printing is perhaps the growth of pigment inks. Pigment ink printing is driving growth in digital textile printing as an alternative to dye-sublimation as well as other kinds of dye-based printing, be it analog or digital. The killer app for pigment inks is their versatility; one ink can print on a wide range of natural and synthetic fabric types, and don’t require the extensive washing, steaming and other water-intensive pre- or post-printing processes, which makes pigment inks an environmentally friendly alternative to other textile printing methods.

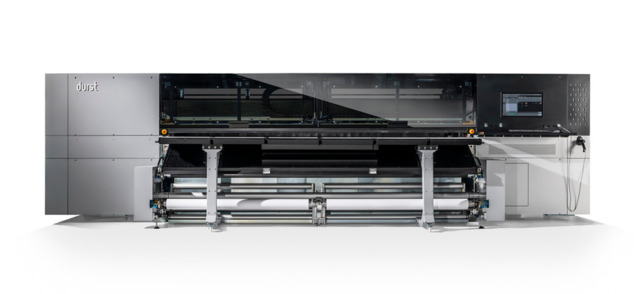

Before March’s FESPA was cancelled, Durst had been looking forward to continuing to show off its P5 digital production platform, which had been launched at FESPA 2019 in Munich with the P5 350 and P5 210 printing systems, and has since grown to include the 250 HS and 200 HS. Durst is heavily involved in a variety of sectors—display and signage, corrugated and packaging, industrial printing, as well as textiles, and had been looking to use FESPA to showcase its pigment-based textile printing capabilities.

The Durst P5 platform.

Direct-to-garment (DTG) printing is a growth area, and earlier this year Epson launched its first “industrial” direct-to-garment unit, the SureColor F3070. It can print custom garments on variety of fabric types including cotton, linen and rayon, at a speed of about one full-size shirt in about a minute.

The Epson SureColor F3070.

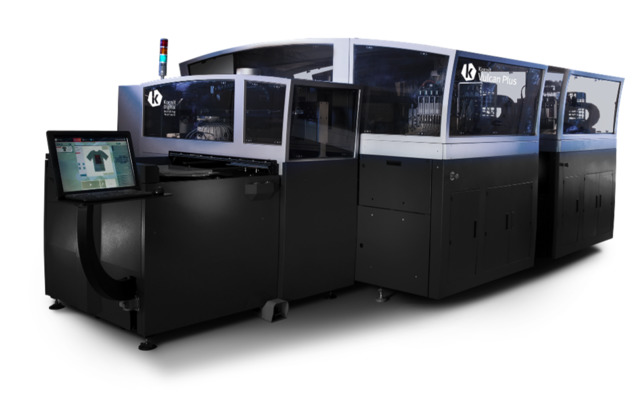

Kornit has been a long-time player in the direct-to-garment arena, and back in January (you remember January?) at Impressions Expo, the company introduced its Kornit Vulcan Plus, a next-generation system for DTG mass customization, capable of delivering more than 2,000 retail-quality impressions in a 12-hour shift. Kornit also launched the Storm HD6 Lite system, bringing industrial DTG printing to smaller businesses. The Storm HD6 Lite is specifically designed to allow commercial printers to move to the industrial market and broaden their production capabilities.

The Kornit Vulcan Plus.

Mimaki has also been pretty active in the textile printing space; for an update on what they have been up to, see the feature on page 44.

Finishing

As in commercial printing, finishing is an important consideration for wide format and signage shops. While that primarily means a rollfed X-Y cutter for paper, vinyl, or other soft materials, large cutting tables can improve productivity and expand the number of applications that can be produced.

Improvements to cutting tables boost speed and various kinds of automation—be it software- or hardware-based, involving conveyor systems or robotic arms that load and/or offload printed boards. The tooling also increases on a regular basis, and there are hundreds of swappable tools that a table can support that offer a great deal of flexibility in what and how you can cut. It’s not just knives; tables also support routers which “rout” or bore out board, plastic, wood or other thick material, and there are tools for tables that can mill, perforate, crease, engrave and even create Braille lettering. Some tables can also automatically swap out the tooling, based on the parameters specified in the cut file.

Once a rare and pricey option (like many things...), laser cutters have been coming into their own. Cutting tables from Esko (the Kongsberg line), Zünd, Gerber MCT and others offer laser modules that can be swapped in and out, while companies such as Trotec Laser offer their own dedicated laser cutting systems and tables. For a closer look at laser cutting for wide-format and soft signage, applications, see my feature “Cutting Remarks” in our May issue.

A company that has just come on my radar is Italy’s SEI Laser, a 40-year-old manufacturer of laser cutting systems, including some specifically designed for wide-format applications. Specifically, the SEI Mercury is designed for cutting, kiss-cutting, and marking on a variety of materials such as poly(methyl methacrylate) (PMMA), acetates, Acrylonitrile butadiene styrene (ABS), micanite, wood, hide, paper and cardboard, textiles, marking on glass and marble (excluding PVC and polycarbonate), thin ferrous and non-ferrous metals.

The new SEI X-Type laser plotters are designed for cutting and marking on paper, card stock, leather and faux leather, hide, natural and technical textiles, rubber, wood, plastic, glass, marble and more.

The Road Ahead

By the time you read this, hopefully we will be on track to head to the fall events for the next wave of product and technology introductions.