drupa news: Are You Ready to ‘Touch the Future?’

Some 300,000 show-goers soon will pack their bags for Dusseldorf, setting out to see more inkjet disruption -- and lots of new printing presses.

With mere weeks until the 2016 edition of the mega drupa printing trade fair in Europe, the wait is nearly over. On May 31st the visitors will begin their pilgrimage to Dusseldorf, Germany, prepared to “Touch the Future” of the printing industry. The big show has moved to a three-year cycle and been shortened to 11 days from 14, but still some 300,000 attendees are expected to crowd the halls and beer gardens. And what will they see? One highlight will be the drupa innovation park (dip), which features six themed sections. 130 companies – from publishers and partners to trade associations – have joined dip.

It has been said that new press technologies buoy the printing industry, and there are plenty of new models to see at drupa 2016. Among other pre-announced highlights are Xerox’s first cut-sheet inkjet press and a new B1 continuous-feed inkjet; no fewer than five new Indigo models and three new Pagewide web presses from HP; and the Primefire 106, co-developed by Fujifilm and Heidelberg (and showing in the latter’s stand) that targets industrial packages requiring versioning capabilities. Of course, print proponents from around the globe are wondering whether Benny Landa’s nanographic printing press is (finally) ready for prime time.

And, there are more! Here, in alphabetical order, are additional details about what 24 of the 1,650 exhibitors will show at our industry’s biggest show:

Bobst

Swiss finishing expert Bobst will feature details on five machines, reported Stephan Marz, who heads up the firm’s business unit services. The Mastercut 106 PER diecutter, which has “reduced set-up time by 30 percent,” Marz added, will make its world premiere at drupa 2016. Bobst also will show a the Masterfoil 106 PR hot-foil stamping press first introduced in 2015; it incorporates Foil Unwinder+, a system that delivers up to 30 percent more press productivity and a reduction of up to 50 percent in foil use. A new Masterfold folder-gluer also will be launched at the show, featuring increased automation, shorter set-up times, lower running costs, and easier use. This machine will allow packaging manufacturers to realize ‘zero fault’ production, according to Bobst.

Also, a brand new version of the M6 UV flexo press, configured with folding carton production in mind, which will challenge offset printed carton production by offering job changeovers in under a minute -- thanks to Digital Flexo technology; high running speeds; and high-speed inline sheeting. Cartons produced on the line can then be converted using the Bobst die-cutting and folding & gluing equipment available to most carton makers. The seven-color M6 offers what no other press in the market can: the cost benefits of purchasing board on reels, allied to the production benefits of the no-water, no-solvent, fast changeover UV Digital Flexo process. And, the MW 85F CI flexo press, a mid-web device that runs up to 500 meters per minute, also will be shown. Bobst is celebrating its 125th year in business in 2016.

C.P. Bourg

Displayed in live action at drupa 2016, the Bourg Preparation Module (BPM) is the industry’s first scalable sheet preparation module for intervention-free book making and binding. The modular prep unit empowers print professionals to use their inline Bourg binders or booklet makers to produce books and booklets with no operator intervention. The new BPM delivers economies of scale, a streamlined workflow, and shorter turnaround times: Sheets are converted from large to small formats in a single pass, enabling multiple book or booklet formats from media of a single size. BPM works inline with select digital printers and presses, as well as off-line, or in dual-mode connected to a Bourg Sheet Feeder (BSF), to create perfect bound or stitched books and booklets.

The unique approach of the BPM creates a more streamlined workflow. Printers can print on large sheets with multi-up imposition, which optimizes their click charge. Additionally, the BPM eliminates or reduces many time-consuming processes, such as preparing media in multiple sizes, manually setting up machines, and trimming finished jobs – all while minimizing human intervention and the risk of human error.

Canon

As its social-media hashtag communicates, Canon is prepared to #unleashprint in its drupa exhibit, which will span more than 4,000 square meters. The company will show the ImageStream 2400 for the first time in public. drupa also marks the world premiere of the Océ ColorStream 6000 Chroma, a continuous-feed inkjet device. Featuring the new Chromera ink set, this model expands the successful family of ColorStream presses, of which 450 units are already installed across Europe, according to Canon. Also in the Canon stand will be the VarioPrint i300 sheetfed inkjet press (with enhancements) as well as the imagePRESS C10000VP and 8000VP models.

The firm reported that it now has more than 114 inkjet towers in Europe, the Middle East, and Asia, garnering a 60 percent market share, not to mention 15,000 imagePRESS customers worldwide. (Some 80 imagePRESS C10000VP high-performance units have been shipped to customers across Europe, said Mark Lawn, marketing director of Canon Europe.

Datalase

Datalase will debut Variprint Inline Finishing at drupa. The one-color, laser-reactive ink technology runs at two meters per second, producing up to 100,000 per hour, “either identical labels or unique,” said business development VP Mark Naples. A strategic-partner announcement is forthcoming in Dusseldorf, Naples added. He also hinted that a multi-color solution is coming in 2017.

EFI

“#PrintIsEverywhere,” said EFI CEO Guy Gecht: on packaging, on garments, etc. Increased print volumes – between fabric, UV, and ceramic tile -- explain why its ink volumes are up organically by 30 percent – “or 15 times faster than Apple iPhone sales. Who would have believed this four years ago,” he asked? The firm, which is on pace to reach $1 billion in sales by year’s end, is set to make major announcements in Germany around inkjet and water-based ink developments.

EFI’s vision of the future encompasses running “smart machines from the cloud,” he explained, using “software that maximizes productivity. Print of the future is all touchless. The only thing you want to touch is the future,” he jested. While he would not reveal specific details, Gecht did share that EFI will unveil a corrugated inkjet press. The as-yet-unnamed product combines the best of the company’s VUTEk, Jetrion, and Cretaprint models, he added. “It is revolutionary.” So, stay tuned for PN’s reportage from the show floor in Germany!

Epson

Tripling inkjet production by 2018, Epson is investing 20 billion yen in its factory in Japan, reported Suneo Murata, COO of the firm’s newly reorganized Professional Printing Solutions division. “Compact, precise, and energy-saving define Epson’s product development for production printing,” Murata said, noting that Epson boasts approximately 50,000 live patents. As part of its exhibit at drupa, Epson will have five zones covering prepress, sign & display, labels, copy shops, and technology. In the wide-format realm, it will show the new SureColor-P10000 featuring a built-in sensor for color calibration. (The SureColor-P20000 was shown for the first time in Europe at the FESPA show in March.) There also are new features for the SureColor T Series of 36- and 44-inch-wide printers.

Esko (X-Rite Pantone, Enfocus, and MediaBeacon)

At drupa, Esko will showcase a range of innovations together with sister company X-Rite Pantone and subsidiaries Enfocus and MediaBeacon. The main part of the 900-square-meter stand will consist of six Inspiration Zones that will take visitors through each step of a typical packaging production workflow. Each zone features solutions and key innovations from exhibiting companies: 1) Brands, Specification & Briefing; 2) Design; 3) Artwork & Repro; 4) Flexo Platemaking; 5) Printing & Ink Management; and 6) Finishing.

In addition to these Inspiration Zones, Enfocus offerings will be present in the booth and Pantone will occupy a dedicated zone to display and sell its well-known Pantone guides and tools for color inspiration and design.

Fujifilm Graphic Systems

The focus for Fujifilm at drupa will be print resource savings and new inkjet technologies, announced Hisanori Makaya, president of the firm’s Global Graphic Systems Division (GSD). Its Jet Press 720S features 20 percent better uptime and an inline UV coater, which will be shown in Germany. (Some 70 Jet Press 720S models now are installed, making it the “leading inkjet press in the world,” said Takuo Ito, director and corporate VP of GSD. Fuji also will show a new, 54-cm-wide UV LED-cured inkjet press for flexible packaging applications at speeds up to 50 meters per minute. The yet-to-be-named model features nitrogen purging technology to minimize odor. And making its wide-format debut will be the 3.2-meter Uvistar Hybrid 320: a flatbed-roll printer combo ideally suited for signage, posters, banners, POP, and POS on a range of substrates.

Global Graphics Software

Global Graphics CTO Martin Bailey said his firm will announce a breakthrough in high-speed inkjet quality at drupa. “Intelligent software is as critical a component as the print head, media, ink, fluid control, paper movement, electronics, etc.,” he noted. The firm’s Harlequin v.11 RIP is faster than ever, with more processing speed. It also addresses image irregularity: “Microscopic affects cause visible artefacts,” Bailey warned. HP SmartStream Production Pro 6.0 is based on Harlequin 11, which can be seen at drupa 2016 driving an Indigo press at the HP stand.

Heidelberg

The aforementioned Heidelberg Primefire 106 digital press, developed in conjunction with Fuji, employs Samba inkjet print heads from Fujifilm Dimatrix. “The new B1 machine enhances the range and application of Fujifilm inkjet technology from our proven Jet Press 720 series in the B2 space,” said Fujifilm chairman and CEO Shigetaka Komori. “Fujifilm will continue to innovate and deliver value to the growing digital printing industry by expanding our core inkjet technologies which is the cornerstone of this new B1 machine.”

In postpress, Heidelberg will present the new models of the Stahlfolder TH/KH 82-P folding machines, where the “P” stands for enhanced performance, productivity, and reliability. With up to 50 percent higher productivity, this series is aimed at industrialized commercial printers with peak performance machines from the Speedmaster XL series or book binders with an annual production of over 40 million sheets.

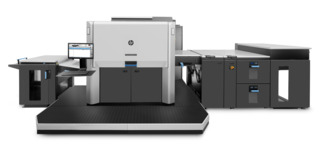

HP Inc.

Focused on high-value and high-volume print, the HP Graphic Arts slogan for this drupa is “Reinventing Your Possibilities.” As the largest exhibitor at drupa 2016, taking over an entire hall, the digital press manufacturer is expanding its commercial printing fleet with eight new Indigo and PageWide web presses. The new portfolio includes three sheetfed presses, the HP Indigo 12000, 7900, and 5900 Digital Presses; the oversized B1-format duplex HP Indigo 50000 Digital Press; and the HP Indigo WS6800p Digital Press for photo specialty applications, Additionally, an improved HP Indigo 20000 Digital Press now is equipped for commercial applications.

Expanding the High Definition Nozzle Architecture (HDNA) technology-powered HP PageWide Web Press portfolio (formerly the Inkjet Web line), the new T490 HD, T490M HD, and T240 HD models provide customers with increased print quality and higher productivity than had been previously possible -- leading print service providers to transfer more high-value commercial print applications from offset to inkjet, HP hopes.

Also launching at drupa: the PrintOS cloud platform from HP. PrintOS will “reinvent print production,” explained Simon Lewis, formerly of Scitex and who now is business director for HP Graphic Solutions. In field testing since last August, the system is being used by 40 HP customers with more than 100 Indigo digital presses. It features open application program interfaces (APIs), so is compatible with programs such as Aleyant Pressero and Pageflex web-to-print software. Lewis said that mobile apps for Apple and Android products will be available by year’s end.

Hybrid Software

Hybrid Software will demo its packaging workflow product and CloudFlow, which features a centralized database, at drupa 2016.

Kodak

In 2012 at drupa, Kodak Graphic Communications launched 10 products that “now are the backbone of the ‘new’ Kodak,” recalled the firm’s worldwide GM John O’Grady. At this drupa, live imaging of process-free Sonora XP and Electra Max plates will be featured in the Kodak stand, as will a new NexPress digital press model: the ZX3900 that features one-pass opaque white ink and can handle thicker paper and synthetic substrates for labels, tags, and small folding cartons. For flexographic package printers, the new Flexcel NX System is launching at drupa 2016.

Kodak Ultrastream high-resolution print heads also will be showcased. From the standpoint of nozzle cost, these new heads will compete with piezo-electric, drop-on-demand inkjet, said inkjet president Philip Cullimore. However, with a proposed spin-off of its Prosper inkjet-web press business, the company’s future still is a bit up in the air and uncertain. Some industry observers contend that a bidding war for this business may accelerate in Germany: interested suitors may include Bobst, Heidelberg, or, perhaps, Konica Minolta.

Kolbus

The Luxury Packaging Division of print finisher Kolbus will demonstrate fully automated production of cardboard boxes with lids and magnetic fasteners. Around 30 percent of Kolbus’s finishing sales now are enabled by digital printing, reported managing partner Kai Buntemeyer.

Printing History 101: It is interesting to note that Kolbus was among the 527 founding exhibitors of drupa at the show’s inception in 1951.

Konica Minolta

Listen to the music: 2016 marks Konica Minolta first time exhibiting at drupa, and its stand will feature a live band doubling as a “commercial printing client.” All the promotional print a band might need will be produced on the show floor in Dusseldorf; much of these materials will be enhanced with metallic foil and varnish effects from partner MGI and its JETvarnish 3DS machine. Launching at the European fair will be Markomi marketing automation. The KM-1 inkjet UV press (B2 format) also should be on display there. This press’s first beta site has been revealed: Print Logistics Services (PLS) in Germany.

“Konica Minolta has 12 years in production printing, and we want a bigger profile,” explained international marketing GM Olaf Lorenz. “There is huge opportunity here and in industrial printing, too, with [digital] label production” from devices such as its bizhub PRESS C71cf.

Landa Group

In Hall 9, Landa Group has doubled the size of its drupa stand to 3,000 square meters and will unveil a trio of new presses in Dusseldorf: The S10P is a 13,000-sheet-per-hour, 41-inch (B1 format) digital perfecting press for commercial print applications; the S10 sheetfed press is designed for folding carton and point-of-purchase (POP) work; and the W10 is a 656-fpm web-fed nanographic press (also 41-inch) for flexible packaging. The W10 prints up to eight colors on plastic packaging films, paper, carton board, and aluminum foil.

“Fourteen years of nanotechnology research has enabled us to make tremendous breakthroughs in the quality, speed, and cost of printing for flexible packaging,” said chairman Benny Landa. “The Landa W10 Nanographic Printing Press produces gravure quality printing -- at production speeds -- on a broad range of substrates from plastic packaging films to metal foils, from paper to carton. Finally, there is a solution that meets the needs of the flexible packaging industry for affordable short-to-medium run lengths of highest gravure-quality packaging materials - with flexo-competitive costs and productivity. We expect visitors to our stand at drupa to be completely blown away by the amazing performance of this press – for which we will be taking orders at drupa.” He added that his research has enabled tremendous breakthroughs in the quality, speed, and cost of printing. “Landa Nanographic Printing Presses produce offset quality, and now at offset speeds and offset-competitive cost per print - on virtually any paper stock.” Presses will start shipping in early 2017, the firm announced. Landa’s theater shows will take place five times a day at 10:30, 12:00, 13:30, 15:00, and 16:30. Register here: www.landanano.com/drupa

MBO

At drupa, in Hall 6, Booth B40, MBO and its subsidiary, Herzog+Heymann, will present 11 finishing systems covering offset print applications, digital print applications, and specialty applications including direct mail, pharmaceutical finishing, and packaging. MBO will show new finishing solutions that help printers optimize high-speed presses and improve production efficiency with its advanced finishing technology. One such machine on display is the web-fed K8-RS Folder, the world’s fastest folder. Introduced in 2014 as a palletized folding solution, the K8-RS web-fed folding system will make its debut at drupa, demonstrating the speed and versatility of MBO’s modular approach to finishing. MBO K8 Automation will also be on display and live job-changeover demonstrations will show visitors first-hand how automation greatly improves make-ready times.

MBO also will display a new high-speed folding system that outperforms even the K8-RS. This system features new technology capable of speeds and productivity unmatched by any machine currently on the market -- something highly sought after by printers who process signatures in high volumes.

Herzog+Heymann will highlight four specialty finishing systems throughout the show. Creasing and grooving finishing technology, a Vario line for merging individual sheets, and new pharmaceutical finishing technology will all be on display. Also on display is the company’s popular Stamina line - a folding carton system with an integrated rotary die cutter from Bograma AG. By combining the rotary die cutting and folder-gluer processes, printers gain the ability to produce “nickless” folding cartons in one pass -- eliminating the need for additional production steps like refining, because the product is cut without holding points that are required in a flatbed die cutting system.

Pitney Bowes

At the Pitney Bowes booth, themed “Real Impact,” the Accelejet, Relay Communications Hub, OneSort, Epic, Sendsuite Tracking Online, Spectrum, and the latest Clarity solutions suite all will be presented. The Clarity Solutions Suite, which is a software-as-a-service (SaaS) offering, leverages the power of the “industrial Internet,” explained Grant Miller, Pitney Bowes’s VP of operations and product management. There are thousands of machines now in the field, collecting data and using predictive analytics and prescriptive maintenance to yield higher response rates for highly targeted mailings.

Pulse, a new mail inserter featuring a compact footprint, also will launch at drupa. Additionally, demonstrations of EngageOne interactive, personalized videos will be shown as part of the Pitney Bowes exhibit. The company has four speaking slots in place at drupa including a keynote speech by Christoph Stehman, the head of the Enterprise business unit.

View PB’s own “Craftsmen of Commerce” video here: www.printingnews.com/12175266

Ricoh

Ricoh’s theme at drupa 2016, its third time at the big show, will be “Open New Worlds.” “Print is more alive than ever before,” proclaimed Peter Williams of Ricoh Europe. Fact: In the past year production print has grown some 15 percent for Ricoh. The Japanese manufacturer will show its Pro VC6000 digital press with enhanced speed and also the Ricoh Pro C9100 Series. Also look for Ricoh to break into the wide-format print space in Germany: “We are determined to move ahead on the wide format,” proclaimed Benoit Chatelard, VP of the firm’s Production Printing Business Group.

Ryobi MHI Graphic Technology

Ryobi MHI Graphic Technology Ltd. (RMGT) will showcase a 9 Series Long Perfector, a 10 Series Packaging, and DP7 Series Digital Presses at drupa 2016. With a sharp focus on core print production requirements of today’s printing companies, RMGT will exhibit real world solutions to real world challenges in the key market segments. In the offset print segment, the manufacturer’s leadership in the LED UV revolution will be emphasized with fully evolved LED UV instant curing of perfected print on the highly successful 8-up RMGT 9 Series 4/4 long perfector and full color print and coating on the B1 size RMGT 10 Series 6-color with coater. The RMGT 9 brings digital run lengths into the offset pressroom offering high profitability in run lengths ranging from 750 sheets well into the millions.

Addressing the needs of packaging printers, the RMGT 10 Series is a 1,050 mm, 6-color press that is compatible with a wide range of stock thicknesses ranging from as thin as 0.04 mm to as heavy as 1.0 mm. This press can perform non-stop printing on heavy stock thanks to a newly developed automatic non-stop feeder and delivery shutter. It is also equipped with a chamber coater, and demonstrations will feature varnish coating using an LED-UV curing unit. The press features a PQS inline printing quality control system for quality management of package printing on heavy stock.

The much-anticipated DP7 will make its debut in Hall 16 of Messe Dusseldorf, and this true 6-up liquid toner digital offset press brings RMGT’s legendary quality, durability, and reliability to the digital pressroom for small-lot and variable-data projects. Featuring a 23.5x 31-inch sheet size, 6-8,000 SPH production speed, and adopting the well-established liquid toner imaging process, the DP7 flexibly meets the need for custom print production. Demonstrations will highlight the advantages of RMGT’s fully evolved paper-handling technology, robust offset liquid toner imaging technology, and industrial stacked fusing unit.

Scodix Ltd.

Scodix will present a new digital enhancement platform and additional applications at drupa. Since 2012, the firm has brought its third product to market successfully, boosted its install base from 12 to more than 200 across the globe, and more than tripled the applications achievable with its proprietary technology.

SCREEN

SCREEN Graphic and Precision Solutions Co., Ltd. will present its "Achieve the Extraordinary in Print" theme at drupa 2016. The company will focus on its SCREEN GP i3 – integrated imaging for innovation – development strategy by presenting a range of production solutions that it says will transform the industry’s existing expectations of print. The SCREEN GP i3 concept embodies the market-leading speed, precision, and reliability delivered by the proprietary core image processing technologies developed by the company in areas such as optics, image analysis, and electronic control.

In the commercial printing sector, the rapid development of sophisticated digital marketing, which integrates online retail sites with e-marketing and social media, is driving personalized printing. SCREEN will demonstrate the benefits of high-speed inkjet in combination with marketing automation. In a live demonstration, online web activity will drive the production of highly personalized, high-quality catalogs printed on a Truepress Jet520HD running inline to a Horizon saddlestitching system.

SCREEN GP also will demonstrate its continuing commitment to offset printing by presenting the latest range of its market-leading PlateRite series of thermal CTP devices. With more than 22,000 units shipped, the PlateRite series is one of the international printing industry's top brands, covering every conceivable combination of format, speed, and level of automation.

Standard Horizon and Standard Hunkeler

Standard Finishing Systems is partnering with Horizon International of Japan at the upcoming drupa event to demonstrate the most comprehensive display of finishing equipment at the fairgrounds. Under the theme “Change the Focus,” Horizon will unleash the hidden value of postpress in a 16,000-square-foot booth showcasing 24 working systems.

Switzerland-based Hunkeler AG, a world leader in high-performance paper handling systems, will show a comprehensive portfolio of unwinding, rewinding, cutting, stacking, perforating, punching, web inspection, tracking and folding solutions at drupa. Together with North American distributor Standard Finishing Systems, Hunkeler will demonstrate many world premieres and updates in paper processing and finishing for the roll-fed digital production print market. More than 20 unique Hunkeler solutions will be running at the fairgrounds -- in the Hunkeler booth (located in Hall 8a/C20) and at a dozen additional booths hosted by industry-leading digital print, finishing, paper, and mail inserting partners.

Xante

Xante will be demonstrating its range of solutions from stand D03 in Hall 5.

Attendees can find Xante's entire award-winning product portfolio in hall 5 at stand D03. Visitors will be able to participate in live, hands-on demonstrations of the Impressia Digital Multi-Media Press, ILUMINA Heavyweight Champion Digital Production Press, the Excelagraphix 4200, and Xanté’s revolutionary iQueue Prepress Workflow.

Robert Ross, Xanté Founder and CEO, says, “Attendees will have the opportunity to see our complete turnkey solutions running live at the show. We don’t just tell what our products can do, we show it. We’ve always focused on bringing fast, affordable technology to the market”, Robert continues, “we give our customers the advantage of end to end support, starting with our intelligent workflow through to the output.”

On the Drupa show floor: The Impressia Digital Multi-Media Press and the patented Enterprise High Speed Feed System have revolutionized the envelope printing market with rapid print speeds (up to 78 full color envelopes per minute), enhanced color quality (up to 2400), and the industry’s lowest cost per print (less than 1¢ for a typical color envelope). With the Impressia Multi-Media Press, you can print on a wide variety of stocks including uncoated, coated, NCR, card stocks, textured stocks, label stocks and envelopes (Bar-4, Monarch, standard #10, window). The patented Enterprise High Speed Feed System features an innovative straight feed path that provides a fast and smooth delivery for seamless transitions with any type of media. The Impressia’s ability to output waterproof, high-quality, full-color envelopes is visually revolutionizing mail.

The new ILUMINA Heavyweight Champion Digital Production Press is the next big thing in heavy stock digital printing. It features ultra-thick printing capabilities up to 500gsm (24pt) with resolutions up 2400. You can now offer additional print services like product packaging, P-O-P displays, table tents, door hangers, menus, oversized banners up to 13” (330mm) x 52” (1321mm) and more. The new High Capacity Production Feeder for the Heavyweight Champion increases the input capacity up to 3500 sheets sheets of 20lb bond. This print system uses LED printheads, HD colors and microfine toners to deliver superior images and more vibrant colors with every print. This printer makes short run, on-demand package printing simple.

Now with PlateMaker 7 inside: The ILUMINA Heavyweight Champion with PlateMaker 7 CTP System is the new affordable solution that allows you to produce high quality, high resolution polyester plates without processing or chemicals.

The Excelagraphix 4200 High Speed Wide Format Inkjet printer can print on a variety of corrugated substrates including folded and glued RSC’s, die-cut sheets and flat sheets. This printer is powered by Memjet’s Waterfall Printhead Technology and Xanté’s iQueue Workflow software which allows full color, short-run, on-demand printing making it perfect for personalization, variable data and prototyping. The Excelagraphix 4200 complements existing flexo workflows by offloading minimum quantity orders, improving production efficiencies, eliminating plates, improving color to color registration, lowering waste to less than 1 percent and providing variable data printing capabilities.

Xanté digital print systems are driven by the iQueue Digital Color Workflow. iQueue is the world’s most user-friendly digital workflow software with advanced file management and color editing tools that simplify and consolidate many prepress tasks. iQueue’s intuitive interface features job cost estimating, full imposition, variable data with Intelligent Mail barcodes, QR code generator, barcode generator, spot color creator, sequential numbering and much more.

Xaar

Industrial inkjet technology Xaar will present its range of premium piezo print heads and products, announce a number of exciting new developments, and launch a new Thin Film silicon MEMS technology platform at drupa (Hall 6 Stand C05). Show highlights include the Xaar Print Bar System, the Xaar 501 print head, and the new Xaar 1003 print head (launched March 2016). The 1003 family of print heads, which incorporates Xaar's unrivalled TF Technology, is the latest generation of the trusted Xaar 100x series of print heads. It sets a new benchmark for industrial inkjet printing and achieves the longest maintenance-free production runs in the industry (depending on fluid type and application). With its all-round superior performance, high productivity and versatility, the new Xaar 1003 builds on the market-leading Xaar 1002 and its predecessor, the original and ground-breaking Xaar 1001.

The Xaar Print Bar System adds single-pass inkjet capability to analog web presses. Launched at Labelexpo last year, the Xaar Print Bar System allows users to take advantage of the benefits of digital printing easily and economically to deliver more creativity to their customers. This is a versatile, easy-to-configure solution ideal for personalized, variable data, special effects and short-run printing for a range of applications, including labels and packaging, and saves the considerable cost and time associated with analogue production methods.

The feature-rich Xaar 501 print head delivers excellent reliability, high production up-time and exceptional print quality. It incorporates the unique PrecisionPlus architecture which optimizes the head actuator performance to give more uniform drop formation across the print swathe and, therefore, exceptional print quality. For added reliability, particularly key for harsh environments, users can benefit from Xaar's TF Technology.

Xeikon

In its first major show since it was acquired by Flint Group, Xeikon has a number of headliners prepared for drupa. These include its brand-new Trillium One press, based on the technology demonstration of Trillium at drupa 2012, and Fusion, the “next big thing” in packaging and labels. Since the announcement of its breakthrough Trillium liquid toner technology four years ago, Xeikon has been working to commercialize the first digital press using Trillium technology and will present the brand-new Trillium One four-color press. Capable of running at 200 feet per minute at 1200 dpi, with a print width of 19.7 inches, it combines cost-effectiveness, high quality and speed for the ultimate in digital printing performance. Trillium One is the missing link in the industry for high volume direct marketing materials and publishing such as catalogs. Many of these applications will also be demonstrated during the show. Show visitors wishing to more deeply explore the technology can enjoy a Trillium Virtual Reality Experience and take a peek inside the press to better understand its unique characteristics. A Trillium theatre on the booth also will stage five live daily demos.

Flint Group will have a presence in: Hall 3 where it will talk to visitors about its wide range of consumables; Hall 8a where an information hub will highlight the group synergies and Hall 8b with BasysPrint and Thermoflexx where together they will continue the conversation on the commonalities in prepress. “Our drupa theme is Direct. Dedicated. Digital,” said Danny Mertens, Xeikon corporate communications manager, “and visitors to our stand will see that in action, with innovations across the board. This includes workflow efficiencies with our digital front end, the print engines themselves, our unique consumables and our next-generation approach to finishing. Our stand at drupa will have something for everyone in the printing industry, and visitors are guaranteed to go away with new ideas about how they can expand their capabilities to drive profitability.”

Xerox

As referenced in the introduction to this article, Xerox is ready to “Let the Work Flow” in Dusseldorf. At drupa 2016 the firm is highlighting its two new production inkjet platfoms: 1) The U.S. manufacturer’s first cut-sheet inkjet device: the Brenva HD Production Inkjet Press, which is B3+ format, and 2) the Trivor 2400 Inkjet Press, a next-generation, continuous-feed replacement for the Impika Compact that is some 30 percent faster, running at 168 meters per minute (200 mpm in monochrome) across a 20-inch web. The sheetfed Brenva HD is “about the size of an iGen,” according to Robert Stabler, a senior VP in Xerox’s Graphic Communications Group. The device is a technology blend, featuring a reliable paper path and the Nuvera stacker. The new press offers “cut-sheet flexibility and inkjet economics,” Stabler added. When Xerox thinks of its digital print opportunity, it thinks in terms of trillions of pages: 50 trillion production pages are printed globally, and only 2 percent are printed digitally, the firm reported.

Packaging represents nearly half of global print retail, which is $400 billion, and is “barely developed in digital,” added John DiVincenzo, VP and GM of Xerox’s Digital Packaging Business. Watch for Xerox to make some package print news at drupa, too.