Create Labels That Pop

With brands facing increasing competition to capture the attention of U.S consumers, packaging and design is more important than ever.

With brands facing increasing competition to capture the attention of U.S consumers, packaging and design is more important than ever.

Not that cool techniques are a recent innovation: the label and narrow web industry have typically employed multiple printing/production processes to create design effects. Converters often utilize and employ multiple printing operations on the same printing line (i.e. rotary screen, flexo, gravure, offset, letterpress, etc.), while also incorporating decorative effects like hot stamping and cold foil, and even special effect coatings—all in-line.

What’s changed is that new technologies are allowing for even more creative design, and for customization as well, much of it, but not only, the result of digital printing.

If there is one brand that gets digital printing’s power it’s certainly Coca-Cola, which is using digital technology to its full effect, beginning with its recent label campaign with personalized names on the bottle. Taking that concept one step further, Diet Coke’s “It's Mine” advertising campaign is leveraging HP Indigo digital printing technology to create millions of completely unique labels.

For a limited time beginning February 1st, every 12-ounce glass bottle features a different design. A select number of patterns will be available on 7.5-ounce mini-cans, 8.5-ounce aluminum bottles, 12-ounce and 16-ounce cans, and 500-millileter and 20-ounce PET bottles.

HP Indigo digital printing technology was part of the design development and bottle production process. Diet Coke created 36 base designs inspired by the bubbles, fizz, taste, and spirit of Diet Coke and then used HP SmartStream Mosaic software to auto-generate millions of entirely new graphics.

“HP is reinventing printing with technologies like HP SmartStream Mosaic Software, enabling leading brands like Diet Coke to reinvent traditional packaging into unique pieces of art not once possible,” said Gary Bernier, strategic business and brand development manager, HP.

With more Just-in-Time deliveries and regional product launches, digital has become the technology of choice for shorter runs, noted Larry Moore, Esko Vice President, Partner Programs, North America. “That said, we are seeing a trend of companies that are building traditional flexo presses that compete close to digital on cost and rapid turnaround,” he added.

For example, The Bobst label press utilizing the REVO production process is nearly as efficient as digital presses in very short runs—with design flexibility that rivals digital. Utilizing technologies taking advantage of expanded and high definition printing, the press can set up a job using as little as 10 feet of material. Make-readies are based on the expanded gamut process and fixed palette ink set theory that digital presses have used for years.

“In the past two years there has been more technology innovations introduced for traditional flexo than digital press,” says Moore. “Digital may offer bigger footprints and faster speeds, but it has been evolutionary—not revolutionary—change. Of course, we'll see what drupa brings.”

Across the board, color plays a major role in creating unique designs. The adoption of expanded gamut color, to a good degree made possible by high definition printing, offers the ability to design with more colors, even spot colors, without stealing press units for spot colors with more flexibility on press.

“The ability to design with the knowledge that there is an expanded gamut with a broader color spectrum allows designers to create more elegant and impactful graphics that attract consumers to products on the shelf,” said Moore.

“With more chroma caused by a seven-color process, images are much more vibrant than printing with only a four-color process. Just as important, these designs can be produced more cost-effectively using flexo—a less expensive process than offset and more forgiving with a wider range of substrates,” he added.

Along with nicer images, high definition flexo is able to more accurately reproduce the images without the tonal compensation that you would normally need to modify with flexo. This means that a designer can more accurately create to the customer's intent—with finer detail and higher quality.

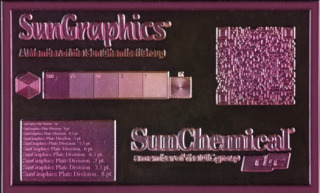

Sun Chemical’s SunGraphics high definition flexographic plate technology, with Esko HD software and CDI high resolution imaging, allows for printing an image quality of up to 4,000 PPI, said Penny Holland, Vice President of Marketing, North American Inks, Sun Chemical.

Printers and brand owners are always looking for ways to distinguish their product through the use of special effects coatings. Sun Chemical is fully vested in the effort, offering a variety of specialty coatings that can offer a variety of multi-sensory special effects.

For example, Sun Chemical’s thermochromic coatings change color with temperature and can be used for hidden messages, interactive games for children, and other sweepstakes and promotional gimmicks, said Holland.

Consumers can also interact with labels that glow in the dark.

Large particles that reflect light at different angles can be used to produce a sparkle or shimmer effect with Sun Chemical’s SunInspire UV Glitter coating. These coatings come in a variety of colors, including gold and silver and can even provide a rainbow effect.

“When applied, SunInspire UV reticulating coatings can give an ‘orange peel’ texture to a print surface of a label, while SunInspire UV emboss coatings are designed to give a raised textured effect,” said Holland. “Pearlescent coatings offer an iridescent luster that can add elegance to the label while color shift coatings can change color based on the angle of view.”

Sun Chemical also provides soft touch haptic coatings, which when cured, can provide a soft leathery feel. Sandy-feel coatings can also be designed to give a rough sandpaper-like texture to the print.

Sold under its SunScent line, Sun Chemical’s printable aroma coatings contain microencapsulated fragrance oils that remain inactive until consumers handle the print and trigger a release of the product’s aroma.

UV inks from Sun Chemical allow brand owners to decorate their glass packaging with bright, vibrant effects that can liven up the shelf presence, said Holland. Sun Chemical’s SunVetro family of organic screen inks, coatings, and sprays are specifically formulated for glass and significantly expand the color gamut versus the FRIT printing process, allowing brand owners to not only produce standout designs directly decorated on the glass, but to do so using real brand colors that meet the current industry regulations regarding heavy metals and VOCs. Special effects from Sun Chemical’s SunInspire special effects coatings can also be utilized.

Smart Labeling

Another big area of interest is smart labels and smart packaging. The increasing interest from CPG’s in new ways to enhance the consumer experience, provide security, and gather data are inspiring companies to develop new and innovative technologies. Beer, wine, and liquor brands seem particularly enamored of the technology, especially as they seek to engage with Millenials.

Anheuser-Busch's special limited edition Oculto beer, featured at a special launch last November, uses smart-label technology with LED lights powered by paper batteries to "further the brand's personality of mystery, intrigue and seduction through a full sensory experience,” reported the brand.

Anheuser-Busch teamed up with award-winning Inland Packaging to create this one-of-a-kind experience. The packaging company used patent-pending technology to create a pressure-sensitive label that uses electronic pathways, paper batteries, micro switches, and LED lights. The pressure switch was strategically placed where thumbs naturally fall on the bottle, so the LED lights shine select Oculto events throughout 2016.

Diageo, a British alcoholic beverages company, also debuted an interactive label in 2015, teaming up with Thin Film Electronics, with the intent of changing the role of the bottle in the consumer experience. Its Johnnie Walker Blue Label “smart bottle," unveiled at Mobile World Congress March 2015, looks to enhance the consumer experience by using printed sensor tags featuring Thinfilm's OpenSense technology, which can detect both the sealed and opened state of each bottle. The tags and the sensor information they contain will allow Diageo to send personalized communications to consumers who read the tags with their smartphones.

Created by Thinfilm in collaboration with Diageo Technology Ventures, the innovation will make it possible to send consumers targeted and timely marketing messages, whether at retail or after purchase, such as promotional offers, cocktail recipes, and exclusive content.

Sun Chemical and its parent company, DIC, are working on materials that provide sensor functions, including RFID, NFC as well as interactive touch through its T+Sun team with Touchcode.

“One of the most innovative developments comes from Sun Chemical’s new EMD5800 nanosilver ink product family,” explained Holland. “The 5800 series offers the advantages of nanosilver technology to a wide range of paper and films materials, enabling high attenuation for advanced RFID and NFC antenna designs on low cost substrates. This further expands the opportunities for convertors to adopt electronic packaging in the form of smart labels into their manufacturing.”