Market Opportunities: High Flying Print Opportunities

Airports can be a great client to court, for shops willing to learn the rules.

The next installment in our Market Opportunities series focuses on Airports. A major transportation hub in cities across the country — and around the world — airports have a wide range of print and signage needs, often handled by a variety of sources. For printers, understanding those needs, and knowing the often complicated process behind filing them, can be a lucrative exercise.

One thing print service providers (PSPs) need to know is that most of the large airports probably have some degree of on-site print shop. It might range from the ability to handle just short-term wayfinding signage to a fully-stocked print operation capable of handling anything that comes up. But we talked to two large airports — Los Angeles and Seattle — and while they do quite a bit of work in house, they also outsource for specific projects and print types.

Both airports pointed out that they do as much as 70% of their work in-house, but some graphics, including advertising, does get outsourced. One of the top requirements they look for when they are getting ready to outsource: an understanding of the rules that govern the airport. “We look for vendors who can communicate effectively and provide us with what we need,” said John Biddinger, manager, Signing & Graphics, Seattle-Tacoma International Airport (Sea-Tac). “They also need to be comfortable with our signage standards manual and the Port of Seattle’s purchasing requirements. For projects where we use an outside printer, our biggest challenge is simply navigating all of the procurement procedures required of us as a public agency.”

He went on to note, “Our in-house sign shop prints wayfinding and informational signage. Most of it consists of vinyl on various substrates; we also print some paper and banners. We have a 54-inch printer, but most of what we produce is 4x8 feet or smaller. The airport also has large-format advertising banners and wall and window graphics that belong to our Airport Dining and Retail (ADR) group.”

The ADR group, Biddinger pointed out, is the most likely to outsource it’s printing needs. “ADR does use a firm called PRR Seattle for design. Magner Sanborn and Stella Color printed and installed the first round of graphics. A refresh of some of the graphics was printed and installed by Image Mill in Redmond, WA. Clear Channel handles advertising.”

For Diane Imori, Leader of our Signage and Graphics Group, Los Angeles International Airport (LAWA), having capabilities that her in-house shop doesn’t carry is a big component when she looks for outside partners. Right now, the inplant operation cuts all of its pieces by hand. “Frankly I would be looking for a company that has equipment that can automatically cut different substrates,” she noted. “There are some machines that are programmable, but they’re very high end and costly. I would want to work with a company who turn those jobs around very quickly.”

Having cutting-edge equipment that the airport simply can’t afford to invest in puts a PSP in a good position to offer services and speeds the inplant simply can’t match. “Since we’re a public agency, with budget constraints like any group, the stuff we have has to get the job done,” said Ellen Wright, director of terminal planning and design, LAWA. “It may not be the most current, but it’s getting the job done.”

LAWA is currently running two Roland DGA machines — a 64 and 54 inch — and has the ability to laminate the pieces after they come off the printer. The airport has broken its graphics needs into a few categories: advertisements, construction and logistics, and wayfinding. The bulk of the wayfinding and short-term signage is produced in house.

Where is the Opportunity?

Talking to both airports, shops who want to get into this potentially lucrative vertical need to know how to approach it, and what types of print they can reasonably pitch. First and foremost, get a copy of the standards the airport must adhere to. Being public entities, they often have to conform to not only strict budget and cost requirements, but also have a set of “look and feel” requirements they need to stick with as well. To have any success at winning airport work, a PSP needs to know exactly what they are up against.

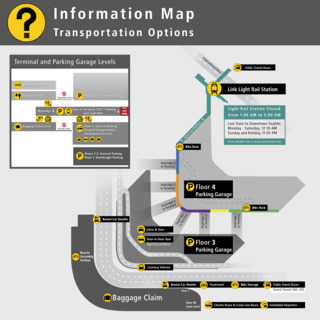

When it comes time to pitch, it is probably safe to assume that, for any of the large airports at least, the wayfinding signage is probably already handled. These signs change frequently as airlines move around, consolidate and construction shuffles terminals around. The likelihood of outsourcing those projects is fairly low, and will be a waste of everyone’s time.

Instead, focus on the things that the airport likely doesn’t have the capabilities to produce themselves. Large format work, in particular, is a great place to start. If your shop has the latest and greatest wide-format machines capable of printing on substrates and creating pieces no one could dream of a few years ago, that might be a great place to start.

Another great area to focus on is the advertising around the airport. Both airports we talked to — Sea-Tac and LAWA — noted an outside agency handles their printed advertisements. Do some digging and find out who has the contract for your local airport, and put in a bid with them for work, instead of going straight to the airport.

Signage is the third place to look for opportunities, especially in retail and dining areas. While these aren’t areas that get refreshed as often as the wayfinding signs, they are probably being rotated every few years to keep the airports looking clean and fresh. This is a great opportunity for a PSP.

“We are constantly making changes to printed signs. Most of our work is driven by construction. Sea-Tac is the nation’s fastest growing airport. That means we are always expanding and changing to keep up,” said Biddinger. “New and remodeled parts of the facility open up. Airlines, ground transportation providers, and restaurants and shops come and go. Some signs may go unchanged for several years, while others need to be updated every few months. ADR changes their promotional campaigns about every two or three years. Ads change more frequently. The fabric advertising signs are a recent addition. They allow for nice looking displays that are easy to change.”

Digital signage is something that PSPs should be taking a hard look at providing as well. For airports, in particular, the ability to update information on the fly is a major perk. And a PSP who can provide that service is offering a powerful service.

“We do have some dynamic signage, and we’re developing more as we go,” said Wright. “Right now we have it for airline info for the most part, in what we call IDS, or information display devices, particularly for airlines in common-use environments. We’re using them more electronic displays; bag claim is a good example. We used to have static signs but now have dynamic signs that can provide more than just the carousel number, they have airline and flight information as well. On the curb we’re moving toward dynamic signage as well, so when an airline moves or consolidates we can quickly let people know where they are.”

“We have electric signs for our primary wayfinding, and we use outside contractors to modify and maintain those,” said Biddinger, detailing one of the few ways a PSP might be able to offer wayfinding services to a busy airport.

It is important to note that this is not going to be a vertical that will be a quick sell. It will likely require meetings with various interested parties, and proving the shop can handle the work it is saying it can produce, for the cost the airport can afford. But once in, it is an opportunity for a PSP to expand into other areas, including other government or public service jobs that will see the shop already has competency in navigating this unique world.