Pathway to Profits: Color is the Key

Is color CAD the pathway to profits? According to experts, it’s one of them.

Imagine all the information that can be quickly and clearly conveyed on building plans through the use of color. Different colors can be utilized to denote crucial building components. Colors can delineate revisions to original plans and can differentiate standard power lines from high-power lines.

Historically, color couldn‘t be used to convey this critical information, because producing prints in color didn’t make sense from a cost or time angle. But that’s all changing, and PSPs are among the many beneficiaries.

Is color CAD the pathway to profits? It’s one of them, said Jamie Sirois, Columbia, SC-based AMS DesignJet technical production segment manager for HP. “It’s one of the areas of large opportunities for quick growth,” she said.

“There is a pent-up demand for color CAD. And there are lots of reasons for that. We found that a lot of our AEC community wanted to print in color, but got stuck at a price point and a speed point of their current printing workflow.

“They’re using color in the designs to denote specific messaging. For instance, red would be for fire, flows of oxygen blue...They’re designing in color and want to print in color. But if they go to their local reprographic shop, the shop will charge them considerably more for color than for the black-and-white drawing. That’s a necessity, because the monochrome devices were very cost effective and fast, the color printers slower and much more expensive.”

The market is transitioning to color, agreed Tim Horn, vice president of sales, KIP North America in Novi, MI. The essential reason for this transition is that color CAD designs are created in color, he said. But color CAD designs are printed in monochrome for reasons of cost and productivity efficiency.

“Color CAD images have traditionally been printed using inkjet systems with limited productivity and high cost,” Horn reported. The technical design community of architects and engineers has always wanted to print in color, but the capabilities to do so hadn’t yet arrived. Now they have.

Color Adds Clarity

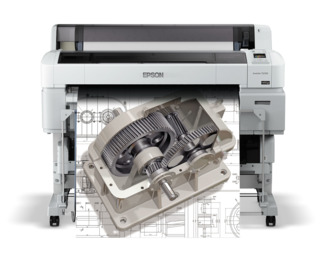

There remains a large quantity of prints that are in black and white, observes Tim Check, product manager of Epson Professional Imaging with Epson America in Long Beach, CA. His sense is that some 90 percent of pages come in black and white, and “they’re very utilitarian,” he commented.

“But color adds a lot of clarity to a basic line drawing. There is a growing number of pages coming in color. In electrical wire harness, for instance, there are different color wires. It’s important to know which is the green, and which the yellow. And having gray scale is not going to help. You have to have color to show that information. You can call that information out with labels, but it’s nowhere near as clear as having it in the color it is going to be.”

Color can also be helpful in revisions, he said.

For example, if a new entryway or door frame is to be installed, changes between the first and second version can be highlighted when color is added to CAD documents, allowing those changes to be quickly identified, Check said.

The volume of drawings printed in print shops is declining as PDFs are pushed out to subcontractors to print on their own. An electrical subcontractor may visit a reprographics shop and report he only needs the nine pages that apply to him. “But here again, color is all the more important for that sub,” he said. “Electrical contractors need to know the difference between standard 12-volt power line, versus higher voltage three-phase power line for HVAC. That can be denoted with color. Call-outs in text can be difficult and very busy. Having them identified in color makes them so much easier to read on site.”

There’s an old saying in construction, he adds. Measure twice, and cut once. Being able to clearly read documents is essential to staying on time and on budget. Failing to be able to clearly read documents can force the need to go back into the job and reinstall plumbing, put in new power lines or change a foundation to a building structure. Those kinds of changes are expensive.

If a reprographics shop doesn’t have color, it may be a deal breaker, Check said. That shop may have a difficult time retaining customers.

So in a tactical sense, is color CAD the key to profit?

“It more a chance to stay in business,” he answered. “But it’s also a gateway to additional work from an architect or engineer, who may want the repro shop to go beyond line drawings to a rendering or visualization in color.”

One thing is for sure, Sirois added. Color is much more impactful, and the use of color enables those who view it to retain more information. “Color documents are more easily understood, and the information is retained at higher levels versus mono documents, up to 65 percent,” she said. “This is my favorite statistic. I’m 65 percent more likely to retain information in a color document than in a mono document. That comes from a Wharton Business School study commissioned several years ago, titled, ’Color for Impact.’”

Decreasing Cost

Until recently, the biggest drivers of cost in color CAD were not just the equipment and inks, but the substrates and slowness of the process, Check said. But printing technology has changed so dramatically that it’s now possible to print directly to bond paper using very reliable print systems. Moreover, whether printing in black-and-white or color, the speed is the same.

“That’s a big change,” he remarked. “It definitely has helped people to say, ’Hey, it doesn’t cost me that much more to print in color. Why not just go with it?’”

Meantime, HP has pushed the limit on cost of ownership of color CAD printers down, and pushed speed up, Sirois said. As a result, HP has found reprographers offering more color CAD, and their prices have started to decline. “So the delta between mono CAD and color CAD is coming down,” she added.

Another impact is that end users at the architectural firms are choosing to buy machines that produce color drawings. They get used to this ability, and have begun pressuring their reprographers to provide color CAD drawings.

Their argument: If we can do preliminary prints in house, you should be able to do final prints in color. “People are designing in color, and have powerful information behind that color,” Sirois said. “They don’t want to lose that power.”

KIP North America will introduce in the third quarter a new lower-cost series of color LED toner-based wide-format print systems, Horn reported. Printers in that series will provide consistent speeds, enhanced production capacity, high print quality and increased profitability for color print services.

What’s Ahead?

Horn reports CAD design complexity continues to increase. Customers want and need color wide-format prints that provide immediate recognition of critical information. “The color print barriers in the market are high cost and one- to two-day turnaround time for color print services,” he added. “New color LED toner technology offers reprographic firms and in-plant print facilities the ability to provide color-while-you-wait service at a lower price point, [thereby] improving customer satisfaction, and increasing color print volume and profitability.”

Looking down the road a bit, Check sees a trend emerging, and believes Epson is driving the trend with the SureColor T Series. “We’re using a very durable archival ink that can be printed in black and white, or in color,” he said.

“It’s water resistant. You can use it outdoors for six months without any fading. That has made these prints more usable on construction sites. But this also opens the door for a printer to have the capability to handle not just all the technical drawings, but the signs and posters as well on one product.”