Crossing Over: From Offset to Digital

As digital print volumes continue to increase, has ‘short-run’ lost its meaning?

It used to be that anything under, what, 5,000 sheets, was considered a short-run job in the offset world. Remember those days? As digital print technology began to take hold, the break-even point shifted to between 2,500 and 5,000 sheets. Today, that number often is fewer than 1,000 sheets, even as little as 500 for some print service providers (PSPs), depending on what they’re printing.

“It is dependent on so many factors that I think you have to break out the different technology types,” said Jim Hamilton, group director responsible for production consulting services at research firm InfoTrends. “I think 2,500 to 5,000 is too high for many applications. Automated offset can be very cost competitive down to much lower run lengths but, of course, it lacks the value of variable-data printing,” Hamilton added.

So, there really is no sweet spot, so to speak, any longer because print process decisions are dependent on so many different job parameters. These days, there are many factors impacting the crossover point between traditional offset production and even among digital options. The crossover quantity “could be 25 or it could be 8,000,” said a spokesperson for one digital press original equipment manufactuer (OEM). Included among the considerations:

- page counts

- printed sheet size

- workflow costs

- prepress and finishing costs

- paper type

- variable imaging

- ink/toner type

“Short runs are in the eyes of the beholder,” explained Will Mansfield, director of worldwide sales/marketing for Kodak’s inkjet presses. A run of 3,000 might be considered “short” by a heatset web printer, he pointed out, “but for a high-end sheetfed printer, 30 copies of a document may be a short-run job.”

Eric Hawkinson, marketing director for Production Print Solutions at Canon Solutions America (CSA) attests to the lure of inkjet printing. “Through the proliferation of inkjet, what we have seen is that when people have a chance to migrate jobs to inkjet, they seize the opportunity to do so,” Hawkinson noted. ”The reason is simple: It’s faster and less expensive.”

Xerox offers innovative software to help understand the true costs of differing printing methods. Its ProfitQuick Job Estimation Tool (JET) is one of several in the firm’s financial modeling software suite. JET helps PSPs to determine the run length crossover point between digital and offset with what-if analysis, detailed job costs, and more, explained Susan Weiss, manager of worldwide business development.

Longer ‘short runs,’ more profits

At the other end of the scale, as digital output gets faster and becomes less expensive to produce, press runs are getting longer. “Digital printing is breaking out of the shackles of short run,” Mansfield contended. With inkjet-web technology, much higher quantities now can be printed digitally. “Runs in the hundreds of thousands are commonplace” for several applications, he noted, adding that in some cases runs “in excess of one million [pieces]” have been achieved digitally.

CSA’s Hawkinson explained a longer-run phenomenon that some customers are experiencing. One printer works with customers to determine which solution is best for their needs. “He shares the cost, quality, and time frame of their toner devices and that of our Océ ColorStream 3900. When prompted with the samples, he has seen a dramatic shift to adoption of the inkjet solution. In turn, this allows their print budget to go farther, often increasing their run lengths,” he noted.

“He said the impact is more than just cost -- it’s how it impacts his customer,” Hawkinson continued. “Their customer is now able to run large-volume, full-variable campaigns for half the price of toner with [the] same or better result. We have seen this growth most evident in direct mail, but as inkjet continues to grow there is no question we see this as prevalent in the other segments, especially in commercial print.”

Toner-based digital devices such as Xerox’s iGen and new Versant lines feature auto color checking and enable a wide range of substrates on which to print. “Beyond the level of automation available within digital presses themselves, production workflow advancements, like our FreeFlow Core prepress solution, are allowing more jobs than ever to move efficiently through printing facilities every day,” pointed out Weiss.

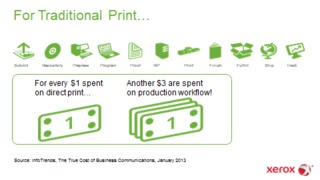

In fact, for every dollar spent on print, some $3 are spent on production workflow, according to a 2013 InfoTrends study cited by Weiss and Xerox (see graphic). “For us,” she said, “it’s all about taking time and dollars out of the production equation for our customers – and that means less human intervention.”

CSA has seen growth in job run length, “but it has become evident that our customers are now experiencing an exponential increase in the number of jobs they are asked to manage,” Hawkinson agreed. “Where our customers used to have 100 jobs, they now have 300 jobs and it has required an intensified focus on automation. Automation software, like our own PRISMAproduction, is vital for a customer’s ability to accommodate this increase in jobs into an efficient process.”

Producing more jobs

A specific example that Weiss offered up is integrated communications provider Henry Wurst, Inc., North Kansas City, MO, which needed to improve its workflow to deliver smaller runs. Wurst provides production of print and digital media, fulfillment, and distribution services, and complete project and program management at its two production and fulfillment centers in Missouri and Denver, CO. A Xerox customer since 1999, the firm’s current digital press lineup includes four iGen presses, four Nuvera monochrome printers, and a Xerox 8250 printer.

Henry Wurst, Inc. enables more than 50 clients with customized web portals for ordering pre-approved marketing materials with order quantities frequently as low as a single printed page. “We often focused on mistake prevention instead of job flow efficiency,” said Troy Fischer, head of process and systems development. “If a shopping cart order for 13 products produced on 65 sheets of paper is sent to the wrong address, to reprint and reship is $20 in shipping alone, $40 if it’s overnight,” said Fischer. “So rework can be very expensive.”

Meeting challenges like this are at the heart of Wurst’s transition from a traditional printer to an integrated communications provider, leading its customers’ migrations from offset to digital print, and from print to digital media. Managing the transition while navigating the sea change in the printing industry has enabled the firm to sustain profitable revenues of about $65 million in recent years.

“Productivity is our mantra now,” noted Fischer. “Hundreds of customized products across multiple stock configurations were creating slow, clunky workflows to our Xerox iGen presses. Many times we were producing at less than 50 percent across a 20-hour day. That productivity- to-efficiency ratio just did not make sense. If we were not able to alter that, we would have needed even more high-speed digital capacity when the math said we already had plenty.”

The core of the issue

Wurst’s web-to-print customers include franchises such as Quiznos Restaurants, with more than 2,000 locations worldwide, and Bonfils Blood Center, with hundreds of blood drives per year in Colorado. From custom portals, these customers can order corporate-approved marketing pieces that can be versioned—for example, to reflect menu variations in different regions or personalized schedules for the time and location of a blood drive.

Orders can include warehoused marketing items and offset-printed materials as well as print-on-demand (POD) pieces, and many contain multiple items. For example, Quiznos has a grand opening package with as many as 200 components; Bonfils has a similar blood drive kit with a poster, several types of forms, and pamphlets on blood-related health issues. “Thirty percent of Bonfils products are for a quantity of one,” Fischer said.

At the PRINT 13 show in Chicago, managers from Wurst came looking for an answer to its quantity-of-one and productivity challenges. They believed they found it when they saw how easily a workflow could be automated with then-new FreeFlow Core, an industrial-strength solution that requires minimal IT support. Among the bottlenecks they saw it address in web-to-print storefront production:

- Job tickets and quality control labels were filled out manually for each of 150 to 200 jobs per day.

- For each of those jobs, digital press operators spent several minutes manually pulling PDF job files off servers, entering job parameters, and submitting them to the correct press queue.

- Cutter operators often needed more time to do time tracking than to complete the cut.

- Manually tracking more than 200 custom POD orders on a daily basis through the post-digital print production processes. As much as an hour daily could be spent by any of five department managers reconciling completion on this order count.

“Integrating with our [EFI] PrintStream MIS system was a piece of cake,” Fischer recalled. "The greater challenge was ensuring specification data regarding order types was consistent across our MIS system and the FreeFlow Core workflow."

The Wurst team developed a methodical approach to activate one client at a time, only after thoroughly testing all the client’s products. But that didn’t slow things down much. The first 15 clients were implemented in only three weeks.

The new process is invisible to clients as they continue to place orders online. But on the shop floor, job tickets and quality control data are now communicated automatically via barcodes printed on banner sheets. Jobs are processed and queued automatically to the target printer. Fewer errors occur, and those that do are easier to track due to the newly enhanced job-tracking system.

Time is money

Among the documented improvements from the FreeFlow Core implementation, digital press operators have reduced the time required to complete their daily work from up to 10 hours down to just two to three hours. Their efficiency—how closely their output matches their machines’ rated output—has climbed from just under 50 percent to near 100 percent. The automation has created a workflow that has all but eliminated the possibility of manual operator-type mistakes from happening. In addition, it allows the department managers the ability to quickly reconcile production through any process at any time. Turnaround is faster and, like the staff, the presses now have more available time to apply to other work.

“It’s like buying a new Xerox iGen press without having to actually spend the capital,” reported CEO Mike Wurst. “We’ve been very pleased with the improvement in our job processes and our ROI is nicely on track.” And as for quantity-of-one orders, what was once an ongoing challenge is now business as usual.

Canon’s Hawkinson concluded, “Workflow cannot be under-stated. It is a critical component of the transition to high-speed inkjet. However, it's important to note the role, or obligation, the vendor has to educate their customers about this transition and how it can foster growth for their company. At Canon Solutions America … this has included offering new tools which enable new applications. Whether it is through education on predictive purchasing and augmented reality, or the development of tools like our recently published ‘Design for Inkjet Guide,’ we are working to drive customer innovation that pushes the boundaries of our inkjet.”

See MPR’s online Buyers Guide for information on short-run digital color print providers.