Thinking Outside the Swatchbook: Paper Turns Over a New Leaf

There are many opportunities to set your ensure your customers stand out on the shelf or in the mailbox by the paper choice that you make.

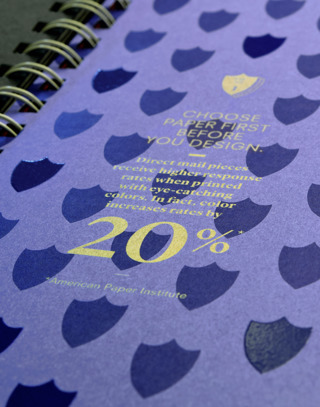

For many print applications today—direct mail and packaging, to name but two—the goal is to stand out from other items in one’s mailbox or on the same store shelf. This is driving everything from specialty finishing, to coatings, to customization and personalization. It is also driving changes in paper choices.

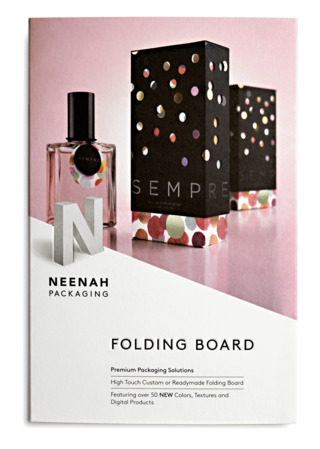

Take packaging. “How do you set yourself apart on a shelf?” said Greg Maze, senior brand manager, Digital and Wide Format, for Neenah Paper. “You do it by looking a little bit different from everyone else. If you make and sell perfume, you put it in a textured box that sets it apart. As a brand owner, there are many opportunities to set yourself apart on the shelf or in the mailbox by the paper choice that you make.”

Touchy Subject

As a result, new textures and finishes are on the rise. “‘High touch’ is the trend in paper,” said Jamie Saunders, senior marketing communications Manager for Neenah Paper. “Today, brand owners truly see paper as a key ingredient of the brand experience they hope to create. We’re seeing more requests for papers that offer unique, touchable surfaces and authentic felt finishes.” Specifically, “pearlized” finishes such as Neenah’s Stardream and Esse brands. “We are also seeing a surprising resurgence in linen finishes,” such as Classic Linen Papers.

Other paper companies have been seeing growth in silk and matte finishes, often at the expense of gloss.

“We’ve already seen, especially in sheetfed work, more silk volumes than gloss volumes,” said Howard Kirby, product manager, Coated Products, for Appleton Coated. “If you’re doing a customer loyalty piece today and you’re an automaker, you’re doing that on silk rather than gloss. But when you want to show off the actual vehicle, then you run gloss.”

There is also a greater interest in synthetic papers. “We’re seeing more traditional offset businesses start printing on synthetics to broaden their capabilities without investing in new equipment,” said Greg Kestler, director of technical products for GPA Specialty Substrate Solutions. “Print service providers are constantly seeking out fresh ways to be a greater resource for their customers, and sometimes the answer is simply to try an avenue they haven’t been down before, even if it’s not new to the industry.”

Variety, it seems, is the spice of printing.

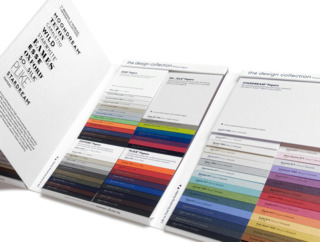

“It’s not just your traditional coated and uncoated papers,” said Kestler. “GPA made a point to include everything from specialty pearlescents and textured papers to synthetics and pressure sensitive papers. The world’s most advanced printing technology is worthless without a variety of high-caliber substrates to run on it.”

A Matter of Continuity

Perhaps the biggest trend in paper is the vast growth in available grades that are compatible with digital printing equipment, especially inkjet, a sector that is changing and improving so fast that virtually every six months sees a completely different paper landscape. Although many print shops are digital only, the majority have a mix of analog and digital equipment, which means that printers want to run the same paper regardless of technology.

“There are not many truly digital print service providers,” said Maze. “Most are a combination of offset, digital, and even wide-format. So as they transition more of their business from their offset to their digital press, they want to use the same products they’ve been using.” It’s about trying to achieve continuity. “If something has worked for them for a long time, they don’t want to change that because they’re running 500 instead of 5,000,” he added.

The challenge with production inkjet has long been the paucity of treated papers available. That has decidedly changed, and a print service provider would be hard-pressed to find an offset grade that didn’t have a reasonably complementary digital grade.

“The continual trend is toward more inkjet-treated paper, so the amount of inkjet treated products becomes broader and broader,” said Ann Whalen, Vice President of Customer Services and Marketing at Appleton Coated. “For example, for lightweight pharmaceutical inserts, we introduced a paper that was ColorPRO-treated for that segment, so the available papers keep broadening.” ColorPRO Technology is designed to optimize papers for HP’s PageWide Web Presses.

Another paper trend is toward thicker stocks, and even an interest in stocks for packaging applications.

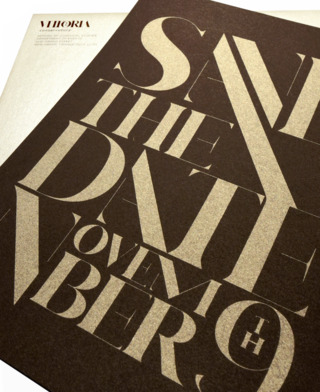

“For years we’ve provided heavier substrates on the offset side,” said Maze. “As [customers’] business transitions from offset to digital, they have to be able to follow suit.” Printing white or gold ink on non-white substrates has also been a trend that Maze has noted.

“Innovations in toner digital printing capabilities, such as the ability to print with white and metallic toner, are driving the demand for substrates that do these new capabilities justice,” said Craig Surette, toner fusion market director for GPA. “Clear synthetics and richly colored papers are seeing a surge in demand for this reason.”

B2 Or Not B2?

What of the so-called “B2” size presses; are they having any effect on paper demand?

“The press that’s had an impact from a size standpoint is the Indigo 10000,” said Kirby. “Despite the fact that the press has a capability of running virtually any size smaller than 20 x 29, the majority of users are still going full-width or full-size.” Kirby hasn’t seen other B2 presses gain too much of foothold...yet. “We do anticipate the 20x29-inch size is going to become pretty standard for both inkjet sheetfed and toner-based and liquid toner-based systems. It’s just slower to develop.” And a lot of continuous-feed inkjet also falls into that size category.

GPA has also been noting the rise of the HP 10000 and B2 presses. “Larger format sheets for digital printing are in hot demand these days,” said Kestler. “Advancements in press technology are driving this need, especially the HP Indigo 10000 press that accommodates B2 sheets. This is helping print service providers be more efficient, run more pieces per sheet, and to take on larger, variable-data projects that didn’t fit on traditional digital equipment.”

Green and Blue

Appleton Coated’s Whalen sees enhanced interest in recycled grades as a major paper trend.

“Customers continue to look for environmental options,” she said. “They don’t want to sacrifice quality, they don’t want to pay a big price premium, but they are trying to meet their corporate sustainability goals. So they’re looking for more recycled fiber.” Appleton has offered a 100-percent post-consumer fiber option for its premium coated paper, and has recently added a 100-percent post-consumer fiber for uncoated. This applies to papers used for both offset and digital technologies.

Wide-format substrates are a whole other kettle of fish, but Neenah’s Maze sees paper- and paperboard-based media for wide format to be a more sustainable option than PVC or other polymer-based substrates for certain applications, such as indoor displays. “Do you need a film, plastic, or vinyl when it’s not being exposed to the elements?” he said. “I would say you don’t.” Paper-based options, such as those offered by Neenah’s recently acquired FiberMark, such as conVerd board, features, said Maze, “the same aesthetics and ease of hanging, and provides an easy blue bin stream.”

Paper or non-paper, some of these same paper trends are emerging in wide-format substrates. “Media for walls is gaining popularity these days,” said Matt Buckley, Wide Format Product Manager for GPA. “There’s a larger selection of face materials available in a variety of textures, opening up more opportunities for merchandisers to create wall surfaces that complement their brand and purpose.”

Beyond the Book

Colored stocks, thicker stocks, and unique textures are all aspects of paper that can allow printed materials to stand out from the competition.

“Marketers are searching for ways to create impact and elevate their messages in crowded mailboxes and on store shelves,” said GPA’s Surette. “Unique substrates paired with eye-catching toner and print effects are helping them do this.”

It should come as no surprise then that some mills are seeing higher demand for custom papers. “For special projects, today’s customer is really thinking outside of the swatchbook,” said Neenah’s Saunders. “They might want to match the finish of a fabric or create an exact match to a brand’s signature color. Customers are asking for more custom solutions and for us, this is great.”

As commercial printing continues to evolve from simple ink on paper to the development and production of high-value print applications, unique and creative paper choices can go a long way to helping marketers and brand owners achieve their objectives.