Specialty Paper That Makes The Grade

What's old is new again--especially when it comes to specialty papers.

Even as digital printing continues its ascent, due to its flexibility, short run lengths, speed, and overall quality, specialty printing techniques including letterpress and engraving continue to be very on-trend.

Trends in paper are following the same trajectory—what's old is new again, said Diane O’Connor, Mohawk public relations director. “We've seen an interest in paper finishes that are similar to fine stationery papers of the past. Finishes like Laid patterns, mid-century embossed patterns, and other historic papermaking methods are trending. We're also seeing a resurgence of interest in historic colors and deckle edge papers.”

Of course, developing specialty products for digital devices is a huge potential area for growth and innovation, remarked Greg Kestler, director of technical products for pressure sensitive paper & printable films, GPA, Specialty Substrate Solutions.

Within the digital printing arena, there is experimentation with integration of textured, colored papers. “With more unwanted communication in the mailbox attempting to gain mind-share —some have called this the Bed, Bath & Beyond effect—the uniqueness of personalized, high-touch communications offers the underdog advantage,” said Tom Wright, senior director of advertising and design for Neenah Paper. “Studies show that the human mind receives information best when it combines the best print has to offer. The sensation of touch. The enticement of the physical weight of paper and the enlightenment of color have the opportunity to create even deeper levels of engagement than ever before.”

Interestingly, as big data is used more intelligently and people are targeted more and more based on analytics, the opportunity grows for personalized communications that achieve a new level of sophistication. “Printers will need to continue to adapt to the power of big data and distribute a personalized catalog or package to just the right shopper at the right time,” said Wright. “However, experienced communicators will need to rely on their knowledge of touch and print to craft meaningful messages that are unique and memorable.”

To capture the consumer’s attention, providing that lofty experience is key across all sectors. In big demand within packaging applications is the desire for unique substrates to catch the consumer’s attention at the point of sale. “Synthetics that are clear or frosty clear using various coating techniques is a popular look that stands out, in addition to foils and other eye catching shiny materials,” added Mary Ann Geers, central region area vice president, GPA. “On the label side, we are seeing the niche craft beer market take off in the digital format.”

When choosing a substrate, the most important consideration is understanding what that sheet of paper will be subjected to from beginning to end, noted GPA’s Kestler. “You need to consider how smooth or textured the substrate’s surface is, in addition to its surface chemistry and compatibility with specific types of presses or inks,” added Ron Pergande, director of digital media, GPA.

Of course, selecting and using the right paper the specific application is extremely important. For any printing job that uses heavy solids, high ink densities, or full bleeds, or for packaging and folding applications with laminating, folding or complex finishing, if the proper paper is not used, the ink and the paper may crack or chip and make the creative, the print, and the brand of the finished product appear mediocre…or worse. “Reprints may be expected at the printer’s expense, brand integrity may be lost, and customers may be lost because of service or quality issues,” said Pergande.

“Other considerations include the advantages and features of the base paper, and if the right base paper has been chosen for the application,” added Pergande. “Also, has the paper been cut in house by ‘the cutter’ from a folio sheet, or has the paper been precision sheeted, converted, and packaged by a world-class converter? In-house cutting can lead to problems, such as excessive paper dust, which can be detrimental to the press, the image, and the finished product.”

Specialty papers often cost more, so it’s crucial to plan ahead and optimize your customer’s print budget by running less expensive papers for makeready. “Get in the habit of tailing in specialty papers on every print run so you can see how they perform and learn their unique characteristics,” Wright stated.

Technically speaking, there are few limitations in choosing substrates beyond the obvious end-use, environmental responsibility, and shelf-life considerations.

“Sometimes lack of experience is a factor, and we fear what we don’t know,” said Wright. “Ask yourself what type of papers don’t you like to print on and why? By knowing where your discomfort level is you can address it by asking questions and seeking out information so you can become expert.”

Added Wright, “Don’t fear what you don’t know: use your work every day to continue to push the boundaries of what you think you can do.”

The reason is that print buyers look for printers who bring excitement and passion to their projects; they want to work with partners who will best help get them where they want to go. “Passion from a printer brings better results nine out of 10 times,” Wright said.

GPA’s Latest Substrates

Within the specialty paper space, companies are offering new products to fill the needs emerging in the marketplace, such as papers that withstand the complex finishing and performance demands that customers require.

“End users are always coming up with challenging applications for point of purchase and packaging projects, and we help them fill those needs with innovative substrates such as clear packaging or laminated synthetic material that offers added durability,” said Kestler

For offset printing, GPA has introduced new synthetics like APET polyester film – popular for its absolute clarity and recyclability, and new Krystal Klear Polyester, which is a PVC-free pressure sensitive synthetic ideal for POP applications, said Geers. “We added new specialty substrates to our offset offering, including magnetic material and mirror-like foil boards that include a 28 pt. micro-fluted product that is popular for premium packaging applications. Our customers have told us they want ways to differentiate their brand and image. These new products definitely make an impression and help them rise above the competition.”

Another new offering is Starlight Photo paper, delivering a combination of pearl with a super smooth surface. “It’s not only a visual treat but also a tactile treasure,” Geers said. “It has the ability to make rich colors really come to life on the surface of the sheet.”

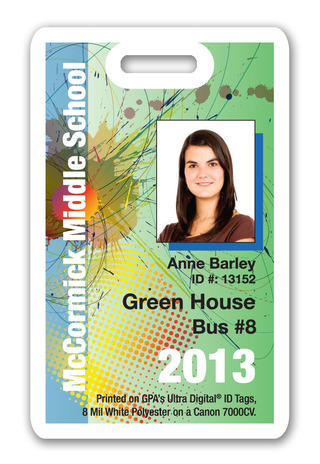

Among GPA’s newer items are pre-converted papers and synthetics for HP Indigo and toner digital presses. These substrates have built-in scores, perforations, and glue strips that make it easy to print and finish in minutes, creating playing card boxes, ID cards, and other specialty applications. “Our customers like them because they can create personalized leave-behinds for even the smallest audiences in almost no time at all,” said Pergande. “Being able to create something that’s personal is more memorable, and that can make a huge impact on presentations, marketing campaigns, and other promotions.

One GPA customer, a national retailer for home goods, recently expanded its offering to include custom furniture and rugs. “They came to our company to find a substrate to make fabric swatchbook covers, which are kept on display racks,” Geers explained. “These covers needed to be durable, printable on both sides, and had to accept grommets to hang on the display. They ultimately went with a polypropylene material that fit the bill, and as a result, the displays still look great and withstand repeated handling beautifully. This is just one example of how a properly selected substrate can make a project a success.”

New at Neenah

Neenah’s newest specialty papers include its RAW finish, part of its ENVIRONMENT offering for both digital and offset —a range of papers that offer a high-touch engagement with superior print performance. Neenah recently revamped its ENVIRONMENT papers line with a new color palette featuring natural colors inspired by the organic lifestyle.

Customers don’t want to have to ‘think’ about the difference between digital and offset,” said Wright. “They shouldn’t have to; so at Neenah we help do that thinking for them, while providing papers that lend authenticity and tactility to the communicator’s message.”

New Neenah Folding Board is manufactured to enable printers and packagers to better support their client’s needs for uncoated paper for premium specialty folding carton packaging. These specialty papers and boards offer a premium print surface and dimensional stability for cosmetics and fragrances, consumer electronics, spirits, confectionary, as well as gift card carriers and hangtags, said Wright. Custom papers can be contoured precisely to fit any specification for color, finish, and caliper.

“Neenah continues to invest heavily in paper sampling tools, including swatchbooks and promotions for a reason,” said Wright. “Printers want them and frequently use them to inspire and educate their customers.”

Each tool, like the new Explore series, features dozens of everyday applications for digital printing. To make it easier for printers, Neenah also offers free dielines for these short-run digital projects, available at http://neenahpaper.com/dielines.

Mohawk’s Offerings

The Strathmore brand name has been associated with innovative cotton fiber papermaking since its beginnings in 1892, and Mohawk is maintaining that heritage with the recent introduction of Strathmore Pure Cotton Letterpress papers, bringing legendary Strathmore quality to a new generation of letterpress printers, said O’Connor.

These papers have been designed to emulate the look and feel of handmade papers, with a luxurious surface that allows for a beautiful contrast between the sheet and the printed impression.

“Strathmore Pure Cotton Letterpress Paper is available in two vintage shades of white, Ultimate White and Soft White and two rich colors, Smoke Gray and Chino, carefully selected to meet the creative needs of traditional social stationers and new letterpress printers,” said O’Connor. The Letterpress papers are available in two calipers: 18 pt for digital printing and 20 pt and 40 pt for letterpress printing. Matching 80 text envelopes are available with square or Euro flaps.

Showing It Up with Adobe Ink & Slide

Adobe crafted a beautiful digital pen and ruler for their contribution to the mobile workflow. Enticing designers, architects and students with software and hardware that works seamlessly with iPad tablets.

San Francisco based agency Character partnered with Uneka to execute the engineering and manufacturing portion of the packaging design. The simple elegance of a hinged box with precise layering of components and materials subtly reinforces the technology within.

The box is made with Neenah premium uncoated papers. Custom dyed pulp cradles and protects the devices, revealing the unique form of the Ink and Slide. The simplicity and beauty of the package design is counter balanced by the execution of form and detail.