Protection, Plus Differentiation

Finishing wide-format print output with today’s textured films and overlaminates still protect -- and add dimensionality, too.

As large-format printers have gotten wider and ink chemistries have been altered, media suppliers have adapted to these changes. “The solvent and latex markets are growing,” acknowledged Ronit McGuthrie, senior product manager for Neschen America. With the growing popularity of ultraviolet (UV) inks, “people think they don’t need to laminate [any longer], but UV inks [can] chip and can leave ‘lawn-mower’ affect lines,” McGuthrie noted. It is a chemistry issue, and suppliers such as Neschen have worked diligently to manufacture a product that will stick to UV ink.

Jerry Hill, VP of new market business development at Drytac Corp., concurred. “UV inks have adhesive challenges on certain substrates,” Hill said. “Low-surface-energy inks are stickier, so there is a lot of lifting.” Minute height differences in ink laydown also can lead to ghosting or air gaps where the laminate “tents,” he added. (See also “Latex Printing: Hope or Hype?”)

Indeed, there is less vinyl with lamination and more direct-to-board (Gator Board and Fome-Cor) work printed with UV inks these days, especially in the intermediate and economy-grade marketplace, according to Jason Yard, wide-format marketing manager at MACtac, which manufactures pressure-sensitive tapes, films, and label materials. “Low prices are wanted, and these laminates have gotten very competitive,” said Yard, adding that most economy and intermediate grades now last six to 12 months.

While the point-of-purchase (POP) market does not require as much durability, some short-term applications may not need UV protection at all, especially if customers only are using them for a weekend, say, or for an event lasting only two weeks. “There are more film and laminate choices than ever,” pointed out Dione Metnick, LexJet product line manager. Choosing a lower-cost option without UV protection can save up to 20 percent on costs, she added.

Not all print purveyors agree, of course. Claude Crumley, production manager at digital print and signage shop Studio Imaging, doesn’t like taking chances. “Everything [used] outdoor should be laminated,” he argued. Located in Bensenville, IL, near Chicago, his operation is a subsidiary of $2.4 million wide-format firm Studiocolor. (See “Graphic Rappin’ on Windows” GIVE MPR LINK.) For extra protection against ultraviolet sunlight, Crumley insists on laminating his window graphics even when five-year materials and three-year inks are used for output on the company’s 64-inch Roland VersaArt RS-640 eco-solvent printer.

The sun’s UV rays are not they only element for which wide-format print needs protection, of course. “The protection of ink is only one aspect,” explained Chad Russell, director of business development at Arlon Graphics, which specializes in cold, pressure-sensitive films. “There are solvent-resistant products, too, as well as abrasion resistance.” In cases of wrapping applications, such as walls and vehicles, laminates have been known to aid in installation and enhance performance, Russell added.

Touchy, Feely

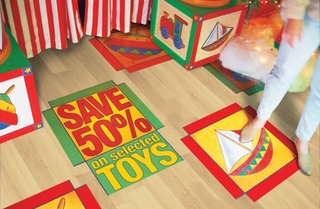

Lamination also can add a revenue stream for wide-format shops, Neschen’s McGuthrie said, playing into the print medium’s often-touted tactile nature. “It is not necessarily an added cost. Face mounting to plexi or glass needs lamination and optically clear adhesive,” she pointed out. More importantly, however, “printers can add dimensionality with finishing, which helps to differentiate them from their competition,” McGuthrie said. “Lamination adds texture to floor graphics, and window graphics tend to have more visual ‘pop.’” (See “Graphic Rappin’ on Windows,” WFI August LINK …) Neschen’s proprietary SEAL Floor Guard is a textured specialty film that prevents glare as well as fingerprint smudges.

Drytac’s Hill calls these textured finishes “funky” on its polycarbonate and high-performance vinyl laminates. For instance, there is a “3D” version that mimics depth-perception graphics; another resembles the surface of ice, complete with cracks. Printers and their customers “use these techniques just to be different,” he suggested. Neschen reported that its anti-grafitti signage, introduced two years ago, is wildly popular. “Our graffiti-resistant product requires no harsh cleaners,” McGuthrie explained, “so the finish does not dull.”

Specialty lamination also has emerged for high-performance and decorative applications, such as high-end tradeshow exhibits and floor graphics that require more durability. “Floor graphics are more prevalent than ever,” reported MACtac’s Yard, “requiring slip-resistance and walk-on durability.” The firm also features the robust PermaFlex line, which is a rigid, pressure-sensitive overlaminate film ideally suited for counter tops and wall graphics. “Our PermaFlex films last 30 to 90 days outdoor and up to three years indoor,” Yard noted.

LexJet has added an 11-mil Blockout PolyGloss media that is resistant to water. The lay-flat polypropylene material includes a gray back coat for added opacity so that less light shines through the back of the graphics. It can be used as a cost-effective alternative to typical polyester inkjet material for trade show and retail displays as well as for long-term indoor and short-term outdoor banners, the firm said. It also offers a 5.5 mil gloss polyester film with block-out layer for 100 percent opacity. The water-based specialty film is intended for non water-sensitive ink and media and “can be used with thermal laminates,” Metnick explained (see sidebar).

Show Time!

Next month at the Specialty Graphics Imaging Association SGIA annual show in Orlando (October 23-25), MACtac will relaunch its PermaGuard intermediate laminate with enhanced matte, luster and gloss finishes, Yard reported. The firm also will showcase face-stock improvements in durability and appearance.

In the spring of 2014, the ISA international sign expo also will be in Orlando (April 23-26). For Arlon, “finish and durability are the keys” at both these wide-format trade shows, Russell concluded. “We will show thicker laminates and adhesives with laminates,” he shared, including its heavy-gauge Series 3590 overlaminate introduced in late 2012. The 12-mil (305 micron) film features a clear, permanent pressure-sensitive adhesive that is popular in racing and dirt bike/motocross circuits. “It is solvent- and chemical-resistant, so it works on industrial and high-traffic applications, too,” he noted.

Arlon also has improved its Series 3220 product. The updated 3210 line overlaminate line is constructed of a 1.3-mil (33 micron) gloss cast vinyl film with clear, permanent pressure-sensitive adhesive. It provides the same protection as the firm’s standard, 2-mil laminates while having excellent conformability during installation with a lighter weight film. “We’re talking extreme curves and channels,” Russell emphasized. Rated for outdoor durability up to seven years, Series 3210 is not, however, designed to be used as an optically clear window film.

Avery Dennison Graphics will show ISA and SGIA show-goers its chrome line of products, which are available in multiple colors. “Silver, blue, and charcoal black are coming,” reported Paul Roba, North American technical manager. Color replacement films for cars and refrigerators, used in lieu of paint, also will be featured. “They [represent]a low front-end investment,” Roba said, “for which we see a market.”

Russell concluded, “Many shops overlook lamination because it is a relatively simple process, but it is a very important step. Mess-ups are expensive because it means starting over,” incurring extra media, ink, and film costs, not to mention associated time and labor. “The challenge with laminating is doing it right – without hurting the graphic,” he said.

Cold and Hot Lams

No print shop should rely on just a few laminates, advised Tim Boxeth, business manager for 3M Commercial Graphics. So, when applying overlaminates, which type -- pressure-sensitive films (cold) or thermal-activated films (hot) -- work best on what kinds of applications? Print volumes play into the process decision as well, of course. “Heat really is a specialty situation,” said Chad Russell of Arlon Graphics.

MACtac’s Jason Yard agreed, saying, “Thermal is a niche application.” Yard explained that heat-assisted lamination is commonly used for menus, brochures, and direct mail – “any printing on board or card stock, generally. A restaurant might need menu boards for 200 locations, for example.” Cold lamination on top of pressure-sensitive media (and sometimes board) “is used for everything else,” he said, “from signage and POP to floor graphics and vehicle wraps.”

To gain the biggest benefit from the laminate, shops must ensure that before they apply the laminate, a solvent or latex printed graphic is thoroughly dried, 3M’s Boxeth recommended, and that a UV printed graphic isn’t over-cured. The manufacturer offers a Product Bulletin GP-1 that can help shops review all options for liquid (see box) and film laminates so they can select the right graphic protection in every instance.

In addition to cold and hot laminating processes, there is a third set, called “heatset,” according to Drytac’s Jerry Hill. “It is more closely related to pressure-sensitive laminates, but they require 24 hours to fully cure.” Heatset operates at 200 degrees Fahrenheit, providing a full cure right out of the laminator. “It’s primarily used for plaques in the décor and framing industries,” Hill noted.

Liquid Laminates

Liquid-based laminates are still highly desirable, said Paul Roba of Avery Dennison Graphics, “but they are thinner and more difficult to handle.” Water-based clear coats, which are applied with rollers, have performance and capability limitations, Roba noted.

At the SGIA show next month in Orlando (October 23-25), Drytac Corp. will introduce the world’s first cutsheet lamination machine. Called the Giclée Coater, the device caters to the smaller volumes for the fine art paper and canvas markets, which “don’t need 150 feet of product,” said new market business development VP Jerry Hill.