Ink: Specialty Inkjet Inks

Printers continue to find new and exciting ways to amp up their businesses by adding new and unique products and services. One of these value added items is specialty inks.

Printers continue to find new and exciting ways to amp up their businesses by adding new and unique products and services. One of these value added items is specialty inks. Some PSPs have delved into the market of the newest brand of specialty inks to increase their bottom lines and to give customers an innovative option to their printing jobs. Some popular products include white, clear, neon and metallic inks. Our experts weigh in on using non-standard inks in the wide-format industry.

Changes Made

Oftentimes when PSPs make changes to their repertoire, there are also changes made in their business practices, processes and equipment.

Reed Hecht, Product Manager of Professional Imaging at Epson America, Inc. addresses this issue.

“With the recently announced Epson SureColor S50670 and S70670, we are offering Metallic Silver (S70670) and High Density White ink (S70670/S50670) options,” says Hecht. “These new inks are different in their formulation from the standard color inks and provide signage and fine art customers with new options for printing on clear materials with the White ink or creating unique signs and fine art with the Metallic Silver ink.“

“New and unique from Epson, the Metallic Silver ink leverages all-new Small Particle Aluminum technology to allow the SureColor S70670 to create a shiny, silver effect and produce true metallic prints in virtually any color.”

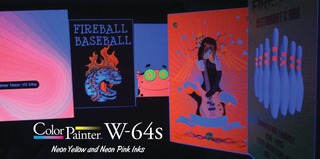

Patrick Ryan, General Manager at Seiko Instruments USA Inc. discusses specialty inks used for their ColorPainter printers. “Neon yellow and neon pink. That’s a specialty ink. Those inks are not neon like neon shirts but an ink that can be used under black light. These are often used by night clubs, casinos, amusement parks, laser tag, bowling centers and more.

When it comes to designing for the use of specialty ink, Ryan says that there are some changes made in the way pre-press must prepare for printing with specialty inks although the changes are minimal.

“There’s a slight modification so you can print the neon inks with the CMYK inks. It’s easy and automatic to configure. Designers simply have to create separate channels or spot colors that will be sent to the printer.”

Hecht continues, “Epson’s high density White ink enables smaller sign shops to utilize the color white on clear media at a competitive price point without some of the negative factors previously associated with White ink, such as being slow and cumbersome.”

Mark Greeves, Director of Sales and Marketing at Color-Logic offers his point of view: “Specialty inks differ from standard inks in several important respects. White inks must be very opaque, since they are often used to obscure a colored substrate or to provide an underlying layer on which an image can be printed when a clear substrate is to be used. Metallic inks, because they have a fairly high concentration of aluminum or other metallic material, can cause problems in some inkjet printer mechanisms.”

When changing processes or adding new services, PSPs can expect changes in costing. The experts discuss how adding specialty inks may change the bottom line.

Hecht says, “We recognize that not all customers want or need specialty inks. Customers can choose at the time of installation to install these inks or to run the printer without these inks for a color-only configuration. Whether the printer is installed with or without the specialty inks, the cost of the unit is the same to customers.

Greeves states, “Because of the low volumes of metallic inks and opaque white inks presently sold, plus the different compounding required, these inks are destined to be more expensive in the foreseeable future. Another factor, generally overlooked, is that graphic designers are not trained in school to use metallic inks. This often leads to expensive press trials and prepress rework in production.”

Ryan states, “Neon inks cost about twice as much as regular inks so the cost structure is higher. The average running cost is .15-.40 per square foot. Although the cost is higher it’s easier to sell in this market because there’s hardly any competition. They can sell [products] for a higher price. The profit potential is there but the customers are harder to find.”

Enhancing the Menu

Part of the challenge of adding specialty inks to a PSPs menu is knowing when and how to use them effectively. Epson reports that specialty inks are especially popular with commercial sign shops and commercial proofing companies.

“Epson has many types of specialty inks available,” Hecht says. “The SureColor S-Series solvent printers are the newer specialty ink products available for our sign, banner and fine art customers. A few years ago we introduced the Epson Stylus Pro WT7900 with the industry’s first aqueous-based White ink. Designed specifically for proofing flexographic and gravure print jobs that require the color white, the Epson Stylus Pro WT7900 leverages Epson UltraChrome HDR White ink, an Organic Hollow Resin Particle technology which forces light to randomly scatter, producing the illusion of seeing the color white.”

Greeves says, “Color-Logic specializes in creating the software files necessary for successfully printing metallic inks or using white ink on a reflective or clear substrate. When the Color-Logic design software is used, designers can create the necessary underpinning white ink masks with just one click of the mouse. This process saves literally hours on every job. Color-Logic also enables print service providers to create their own color charts, thus enabling the designer to utilize color guides that were printed by the exact process and substrate that will be used on the final job.”

Opening Doors

With new products comes the opportunity to open doors with new clients or to boost the sales potential with existing customers. Our experts discuss how specialty inks can be utilized to enhance production and sales.

Ryan believes that while the market for specialty inks is smaller and more specialized, it gives PSPs the opportunity to expand their client bases.

Ryan states, “Neon inks allow you to expand your offerings and your portfolio. Casinos and night clubs are the top markets. In Southern California we also have a lot of amusement parks that use a lot of neon and black light graphics. Of course these aren’t available everywhere but there are markets. For example bowling centers can incorporate local sponsorship into their midnight bowling advertising. The local sign shop will be able to do that.”

Ryan adds, “Most sign shops haven’t thought about that and clearly we are giving them some direction to call on clients that they normally wouldn’t call on for that type of product.”

Hecht says, “Where customers previously had to embellish prints manually, using the Metallic Silver they can do this additional time consuming step automatically on the printer, and provide artists unique ways to take fine art to the next level. And with our high density White ink technology, customers can print on clear materials for signage applications where they may not have been able to before.”

“Color-Logic specializes in creating the software files necessary for successfully printing metallic inks or using white ink on a reflective or clear substrate,” says Greeves. “When the Color-Logic design software is used, designers can create the necessary underpinning white ink masks with just one click of the mouse. This process saves literally hours on every job.”

With changes in production, it stands to reason that using specialty inks also changes the ways in which items are printed. Hecht clarifies:

“Some specialty inks are still new to the market so it may take production shops time to work these new technologies into their standard workflow. Overall, the printing process won’t change drastically other than shops getting acclimated to using these new inks and media types that they may not have worked with in the past.”

Ryan says, “When it comes to trends - we’re all developing healthier greener inks. Each year the next generation inks are healthier without sacrificing what the customer wants such as color and durability. People also want cleaner, greener inks and of course , cheaper.”

Greeves says using specialty inks changes things in several ways. “For example, when printing a conventional color image on clear substrates, a white ink layer must be created on which to lay the color image. This means that the white ink must be applied first. Similarly, when an image is to have a metallic effect, it generally is necessary to lay down the metallic ink first. This means that the printer must be able to put down inks in a specific order for success.”

Greeves also has high hopes for the future of specialty inks. “The widespread use of metallic colors is a perhaps the most significant trend we are seeing today. Label producers, folding carton designers, signmakers, and virtually every other kind of printer are seeing increased demand for metallic printing. This is the basis for the broad acceptance of the Color-Logic design software and the fact that printers are licensing the Color-Logic process in ever-increasing numbers.”