Process Control

Creating a printer ICC profile to achieve consistent, repeatable and predictable color is a process in itself. But the process doesn’t end with creating the profile. You will need to monitor print results to ensure that the printer remains in the known good print condition you created.

What Is statistical process control?

It’s a common misconception that once you profile and calibrate a printer your work is finished. That’s like believing that once you change the oil in your car you never have to change it again.

To make sure your printer is performing to the best of its capability, you have to implement statistical process control.

The first step of process control is to collect data and statistics to calibrate a printer, create a profile and compare it to a pre-determined target or a reference print condition such as GRACoL 2006. You do this through measurement by a spectrophotometer into a verification software program.

If you are satisfied with that comparison, the measurement can be saved as a baseline for your own known good print condition. Then through regular verification measurements compared against the baseline, when the color starts to drift you know it’s time to re-calibrate the printer or perform other color quality troubleshooting steps.

Picking A Color Target

When profiling a printer, you need to decide what color target to use for initial comparison. We suggest using an industry specification for that target. We call these Characterization Reference Prints Conditions, or CRPCs.

According to IDEAlliance there are seven CRPCs:

- Coldset News

- Heatset News

- Premium Coated

- Super Calendered

- Publications Coated (also known as SWOP)

- Premium Coated (also known as GRACoL)

- Expanded Coated (G7 extreme)

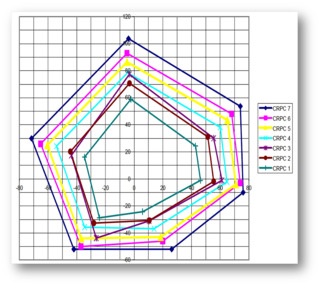

This chart shows the different CRPCs color gamut space at L* 50 as determined by printing to specified CMYK solid ink density. We usually suggest CRPC 6 or GRACoL as a good color target for comparison for printer profiling.

Without a specified color target for comparison, you cannot determine a printer’s profile to be a known good print condition. Most verification software will allow you to choose a color target such as GRACoL for measurement comparison.

You can also use verification software to save these comparison measurements over time. These trend reports can help you determine if and when your printer needs to be re-calibrated.

Gathering Statistical Data

Here’s a hypothetical example of the importance in gathering statistical data for clear communication.

Often a customer’s feedback on a print project will include dissatisfaction with a particular color in the job. Perhaps the printed red isn’t close enough to the expected red according to the customer. You may hear things like, “The red isn’t warm enough,” or “I need the red to be more vibrant.”

While your customer might know what they want in their mind, this type of communication isn’t effective. What is “warm” or “vibrant” to them probably means something different to you.

That’s why we have to use data to communicate about color. There are four stages of working with statistical data: collection, analysis, communication and action.

- Collection: The most important thing about collecting data is determining what data to collect. Verification software can provide an abundance of data; but you don’t need all of it. In the case of this hypothetical customer, they are concerned about red. So you would want to collect data pertaining to that color.

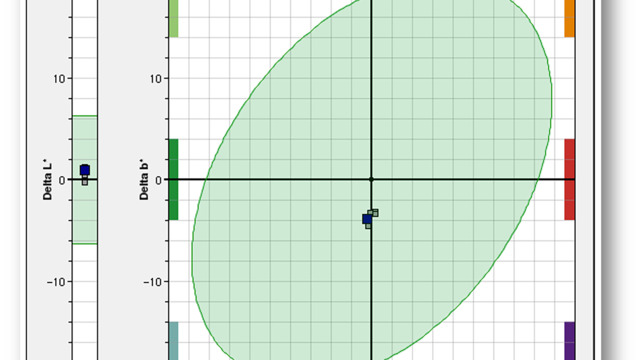

- Analysis: Once you have the data you need, you can analyze it. Do you have a swatch or sample of the expected red to compare it to? Using a spectrophotometer in conjunction with verification software, you should be able to determine how close the two reds are mathematically.

- Communication: Now that you have actual data on both reds, you can clearly explain to the customer the actual difference between the two. Some verification software will even take the data and show it pictorially to more easily examine the difference.

- Action: Once the difference between the two reds is known statistically, you can then determine what action – if any – is needed to adjust for better color quality.

Without clear communication through statistical data, it is almost impossible to achieve the desired color quality.

The Process Control Baseline

Process control is about systemizing what you do. You need to create a baseline. The baseline you create will be unique to your facility and its workflow.

First, you’ll need to choose your preferred color target. Again, we suggest CRPC 6 or GRACoL. Your goal is for your printer to be as accurate and precise as it can be when compared to that target.

Next, you need to decide how you’ll gather your data and what you’ll do with it afterwards. There are many considerations.

- What spectrophotometer will you use to measure data?

- What verification software will you use to analyze the data?

- What are the tolerances that will be acceptable (in Delta E)?

- What data should be collected? (This will probably be decided situation by situation, job by job.)

- Where will the data be displayed and stored?

- What will you do with the data?

- And perhaps most importantly – who will be responsible for the data collection and management?

Once you’ve established a baseline ICC profile for your printer and have determined what to do with the data you collect, you’ll be able to confidently enter the cycle of ongoing statistical process control.

Eventually, your printer will drift from its known good print condition. Many times this happens when a variable changes; such as a different ink or substrate. That’s when you’ll want to verify it against the baseline measurement. Based on that outcome, you can decide whether it’s the right time to re-calibrate your printer and/or build a new ICC profile as the baseline.

Process control is the long game of color management. It never ends. Your baseline profile needs to be monitored and maintained if you want consistent, repeatable and predictable color.