Digital & Offset: A Marriage Made in Heaven

Unifying and automating digital and offset workflows brings a host of benefits.

The print shop is evolving. In the modern world, many traditional offset print service providers (PSPs) are finding they need to add new, digital equipment to expand their capabilities far beyond what they have been able to produce in the past. But adding digital technologies doesn’t mean the offset work will stop—and in some cases it might increase, as the marriage of the two opens up new opportunities as well.

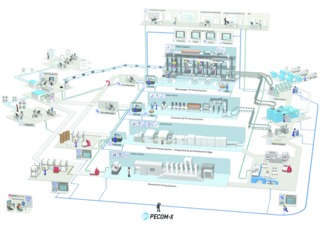

With that kind of mixed technology comes a new challenge: integrating them together into a seamless workflow.

“They should be one workflow, but today, that isn’t always the case,” said Aaron Tavakoli, the Digital Workflow Product Manager for Kodak. “That’s a byproduct of the nature of the print engine and the older, more traditional CtP device and its workflow or RIP. But PSPs need a consolidated approach to both. Jobs originate from the same places—existing customer relationships, Web-to-print platforms, order fulfillment systems, etc.—regardless of where they end up, or which production devices they are routed to. Both types of output need to go through preflight, both need to go through some manner of prepress imposition and the need to automate both workflows is identical.”

“From a print buyers’ perspective, they don’t care about digital or offset, they care about the quality of the product being produced,” agreed EFI’s director of portfolio product management, Nick Benkovich. “They want a simple way to transact with the PSP, and from the front end it is a single workflow. From a management perspective, it’s a single workflow. But on the back end, that’s where it breaks apart. PSPs really should be treating those output devices as just that: output devices.”

One of the biggest benefits to a streamlined, unified workflow is the ability to then automate a lot more of the print process, which in turn leads to the ability to run far more jobs, with a much higher profit margin. “Look at a production workflow not as driving a device, but as driving fulfillment,” noted Jeff Dunham, the product manager – Prinect & CTP for Heidelberg USA.

Dunham’s colleague, Dan Maurer, vice president, Product Management, Digital, pointed out, “From a business perspective, an automated workflow allows PSPs to grow the top line revenue. It makes them more attractive to more print buyers because they are able to provide a one-stop location. Buyers don’t have to shop in multiple places for their work, no matter if they need short runs, long runs, wide format, etc.”

Taking Steps

It’s easy enough to just say “unify the workflow” but getting to that point isn’t easy. Andreas Elchlepp, product manager, Digital Printing Workflow at manroland web systems, noted that the first step is to take a hard look at the current operation. “It needs to be determined if the existing workflow modules are capable of expansion, meaning if there are existing interfaces which could be used for communication with other systems.”

After that, he said, “there should be a clear vision of how the production and workflow architecture looks, to connect the worlds of Offset and Digital. The third step is to define the missing workflow pieces and gaps which have to be closed.”

“When PSPs are looking to run both types of equipment, it’s important for them to measure capabilities of fulfilling jobs, the costs associated with them and the turn-around times,” said Kevin Horey, vice president and general manager, Workflow & Solutions, Xerox Corp. “One of the biggest challenges for a shop is shifting the mindset outside of just using offset. For some shop operators, digital presses are outside of their comfort zones since they’ve been working with offset presses for many years.”

“I think the biggest challenge is the idea of integration,” agreed Tavakoli. “That word is being thrown around so freely and endlessly, it gives the impression that it’s simple. Technology like JDF has made it simpler, but it still requires a great deal of thought and prudence. PSPs have to wade through all the information in front of them, determine what they need, and then once they find a solution, determine if it works with what they already have. And then what do they need to invest in beyond initial cost of the device/engine/software/etc. What is required to get these solutions to work together?”

Dunham pointed out that a unified, automated workflow that is device agnostic isn’t just a one-time investment, either. “The first challenge is for a provider to be able to define their goals. What do they want to look like? What’s important? They should spend a lot of time consulting with providers to help them define what the goal of the project is, and then figure out how to get there. And project is the important word here: it’s an ongoing project to create a unified workflow, to be automatic, to meet the needs of the customers and meet the profitability needs of the shop.”

Benkovich agreed, stressing the need for a PSP to take the time to really analyze their business and what they want to accomplish before taking the first step. “They need to understand what they ultimately want to produce—business cards, brochures, etc., and understand what the market price is for that job type, and then understand what capabilities they will have when connecting different equipment. Not all equipment is the same, and not all connectivity is identical. They have to understand where the device enhances their portfolio or reduces costs, can they add a new product, or produce a product more efficiently than before? It comes down to walking through all the different steps in the workflow, and understanding how each can be automated.”

And it’s not enough to just look at the print output when looking to integrate these workflows, either. The postpress side of the shop needs to be tied in as well, and needs to be able to handle work from both offset and digital presses, or the benefits of a unified and automated workflow are lost on the back end.

“When addressing the integration of offset and digital, one fact is clear: In digital printing workflow, the press is dependent upon the finishing equipment,” stressed Elchlepp. “The finishing equipment defines the products that can be made by the press. When integrating the offset and digital workflow, the opportunities are really tied to the flexibility of formats offered, and how to organize a pressroom, which is creating many different types of products at once. In today’s market, product flexibility means revenue.”

One thing PSPs can do to help make sense of the options and how to implement them in their own unique operation is to talk to the providers. “We offer something unique,” Maurer pointed out. “We do this every day; this is what we do. We see best practices, so treat your supplier as a partner. They can often help you on that journey from a project management standpoint. It is really important to do your homework—and I would talk to several providers. Everyone will have their own slant, and that way you can make your own decisions. If you’re going to do it, you want to do it once.”

At the end of the day, the benefits to having a single, output independent workflow that is automated from the front end to the mailing and fulfillment, far outweigh the pains of getting to that point. It opens up opportunities to produce jobs the shop couldn’t even attempt before, for less operating costs, and in less time, which all leads to happier customers and higher profit margins.

“The key to running a profitable and successful print operation is efficiency,” Horey concluded. “As print—especially offset—is a mature market with ever decreasing run lengths, investments in tools that increase productivity are key. Many printers run both offset and digital workflow solutions that automate the steps to produce more jobs.”