Powerful Digital Front Ends Drive Production Inkjets

High-speed printing puts a big requirement on the DFE in terms of data processing speed and throughput.

Every time a production inkjet digital press manufacturer releases a new machine with faster throughput or an expanded color range, there’s a newly engineered digital front end hovering in the background, ensuring the process improvements are realized.

High-speed printing puts a big requirement on the DFE in terms of data processing speed and throughput, especially when personalization or graphically intense elements, such as live transparencies, are involved, acknowledged Martin Bailey, CTO, Global Graphics. “As the technological limits of inkjet printing in terms of printing speed and width are still a long way from being achieved, we can expect the requirements for faster data processing only to grow phenomenally in the decade to come.”

The HP T400 color inkjet press that is driven by the Harlequin RIP, for example, requires approximately 15GB of raster data every second to keep it running at engine speed. Correct rendering of live transparency greatly increases the amount of processing required per page.

There are two critical factors that can affect how a DFE attempts to drive any continuous feed inkjet solution—resolution and speed, said Nick Fiore, senior manager, product marketing, Ricoh. “A DFE has to be able to have enough processing capability and overall bandwidth to run a given solution at the highest rated speed and/or resolution. When Ricoh evaluates customers' DFE needs, we thoroughly test a variety of application types in an effort to meet and exceed our customers' requirements. Our goal in mind is to always run at full rated speeds and at the corresponding resolutions.”

The biggest challenge, unequivocally, is speed, combined with the quality levels expected, agreed Tod Viniski, worldwide marketing Manager, Workflow & Solutions, Xerox Corporation. In the old days (not even 10 years ago) production inkjet was mainly involved in a classic transactional workflow, amounting to laying down variable data (VD) on top of preprinted shells—and VD was just text.

“Image quality is approaching our graphic communications level versus traditional transactional quality levels,” explained Viniski. As quality expectations rise, along with color coverage, VD and personalization, there are more challenges and more focus on the digital front end.

“The number one concern and the number one question from customers, is ‘if my controller slows down when running 100 ppm, what gives me the confidence to that it can drive a 1,000 ppm machine?’” he noted. “Priority one, two and three is all about speed. The applications that these devices are now running, such as four-color plus direct mail, puts a tremendous burden on the digital front end.”

The number one task any DFE has to do to deliver near-flawless production, is to properly and quickly convert the native data stream to the bitmap images that the printer understands, added Fiore. “To do this correctly, the DFE also has to take into consideration as part of the process, any changes the printer may want to make to the document i.e. color management, rotations, page order, face up vs. face down, etc...and ensure those changes can also be converted.”

Important features to look for in a DFE include which datastreams are supported—such as, at a minimum, AFP, PDF, and PDF/VT. Industry standard color management capabilities, strong imposition, ease of use, support for JDF, and the web interface are also important, said Fiore.

Ricoh’s Pro VC60000 uses a new Ricoh DFE that provides native support for PDF, PDF/VT, and AFP with JDF and advanced color management support. The DFE is optimized for complex data-driven graphic communications, and works hand-in-hand with a suite of software that help ramp up the efficiency and productivity even further.

Historically, inkjet devices were IPDS driven. “But IPDS doesn't have the complexities to get to the graphically rich feature set that is demanded from our direct mail market and even current transactional jobs, which contain high graphic content,” noted Viniski.

“The adoption of a PDF workflow gets you to a more visually rich document,” he added. Because of this, the industry is moving to the point where PDF is becoming the standard.

Depending on your requirements, there are two different controllers available for the Xerox Impika Rialto continuous color inkjet press. PSPs primarily involved with direct mail and commercial work can use the Xerox Impika PDF Controller, based on APPE (Adobe PDF Print Engine) 3.3. It supports PDF 1.7, PDF/X 1a, 3, and 4, as well as PDF V/T.

Xerox also offers the Xerox Impika IPDS controller, which is built for classic transactional jobs. It is compliant to the AFP Consortium (IS/3) format adheres to the latest industry standards.

For those involved requiring both advanced graphics and the performance of a IPDS-based workflow, there is Xerox’s FreeFlow print server. FreeFlow supports an Adobe PDF Print Engine workflow, for an end-to-end, native PDF workflow. It also features subsets for variable data printing (VDP), including operator-defined and data-driven subsets, to allow production decisions like layout and finishing to be independent of data stream construction.

Scalability is also a key consideration for a digital front. A scalable RIP, said Viniski, allows the PSP to match data complexity and printer speed. To ensure your RIP can grow with your company, “match the controller to the printer to be able to produce the most difficult jobs,” he said.

Another concern is the long-term life of controllers, which may become obsolete before the printer they are driving. In this market, where print service providers spend $1 to 3 million on their inkjet devices—not $100,000—they expect the system to last 10 to 20 years.

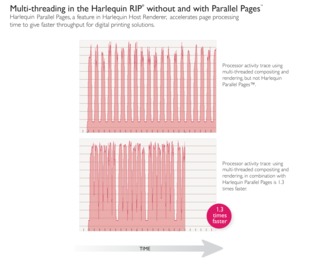

When engineering its RIP, Global Graphics focuses on delivering speed, cost, and quality, and a maximum return on investment, Bailey said. The latest version of the Harlequin RIP is significantly faster than earlier iterations.

The RIP has to be able to perform its functions really fast; otherwise the press is sitting idle, and not getting the necessary ROI to make the investment worthwhile, Bailey notes. Incorporating faster speed, personalization, and a full boat of color capabilities, production inkjet machines are also now a lot more expensive. These are no longer $150,000 models; they now cost well over $1 million.

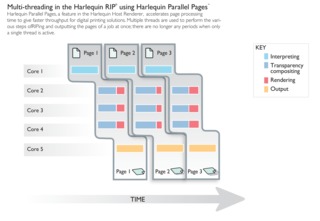

Global Graphics’ Harlequin RIP, which is OEMed to print manufacturers such as HP, offers multi-threading using Harlequin Parallel Pages. Multiple threads are used to perform the various steps of RIPping and outputting the pages of a job at once.

While a version of multi-threading is not new to the Harlequin RIP, the Parallel Pages feature is. Parallel Pages, incorporated into the Harlequin Host Renderer 3, allows multiple pages to be interpreted and rendered at the same time. Basically, by decoupling interpretation from compositing and rendering, one thread is able to interpret page two of a job while the other threads are composting, rendering, and printing page one.

Harlequin RIP also features flexible architecture that allows for high scalability—up to hundreds of RIP instances can be run simultaneously, depending on the architecture of the DFE.

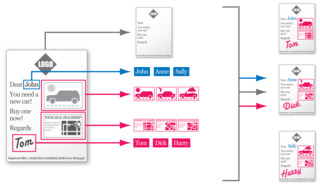

The Harlequin VariData feature speeds up the processing of VDP jobs in PDF, by reducing VDP complexity and enabling the efficient use of objects that are re-occuring. VariData identifies groups of graphical elements that are used multiple times, and then renders each group only once.

PDF Retained Raster automatically analyzes a PDF file to identify those pages that use shared elements. Those shared elements are rendered only once—instead of, let’s say, 50,000 times, while the variable data on each page is rendered separately. The performance increase is significant, noted Bailey.

“Quality is also an issue, with so much demand and discussion on whether digital print has achieved offset quality,” he said. For the RIP, that demand means color management and screening capabilities. Also coming up when talking about offset quality is the absolute need to be able to output logos in brand colors.

With the Harlequin RIP, the ColorPro option can be used to perform in-RIP color management, and also delivers accurate color reproduction and custom rendering intents.

As inkjet machines look to improve the quality of output, output faster, and go wider, digital front ends will have their work cut out for them.