The Current State of Print Automation

What should printers look for in an automation solution, both today and in the future?

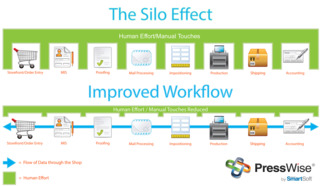

The term “print automation” can mean a lot of things to a lot of people. Most commonly, it is used to refer to streamlining and removing human touch-points from the prepress side of the workflow—things like automatically quoting for jobs, automatic preflighting, allowing customers to upload, approve and put a job into the print queue remotely, etc. In recent years, more solutions have been created to allow progressive printers to take the human element out of the process right up until the product comes off the press. And while shipping and tracking jobs have seen their fair share of automation as well, it’s only now that the industry has begun to turn its automation eye toward postpress processes like folding and finishing.

We might not be there yet, but, noted Mark Bohan, vice president of technology and research for Printing Industries of America, that is the way we are headed. “From where I look at it, we have moved along a long way, but we still have a ways to go,” he said.

In the meantime, there are plenty of options out there for printers looking to automate, and plenty of reasons they should seriously consider it, if they haven’t already.

“The biggest benefit to implementing a print automation system is clearly operational efficiency,” said Tod Viniski, Xerox Corp.’s worldwide marketing manager for its Workflow and Solutions division. “Automation removes the error prone touch points of a print manufacturing process, thus delivering more consistently correct output. Better asset utilization, combined with less process errors, means more is getting done in less time, driving total cost down.”

The vice president of marketing for SmartSoft Inc., Tony Tarpey, went further, breaking down his reasons why every printer would benefit from more automation:

- Fewer touch points mean a more efficient use of resources and increased throughput;

- Greater workflow transparency and accountability;

- Reduced human error, improving consistency and reliability;

- Improved responsiveness to customers;

- The ability to run a greater variety of jobs, including shorter runs that were once unprofitable; and

- Improved margins leading to greater profitability.

“This all translates into cost savings – basically allowing a printer to do more with less, and making them more profitable,” agreed Leslie Wengenroth, Pageflex’s director of marketing and business development. “When implementing a print automation solution, a printer will also gain insights into their process – helping them to identify what the inefficiencies are and what the impact is for them and their customers. A good deal of this also has the potential to impact the printer’s customers in a very positive way – not just through cost savings and faster turnaround, but from increased satisfaction leading to improved customer loyalty.”

What to Look For

It’s fine to say you want to automate your process, but where do you start. For every printer, it has to begin with a close examination of the current way of doing business, and identifying the bottlenecks. If you don’t know where your biggest problem areas are, you won’t know what or how to fix them. And those points can and will be different for every printer.

“Look at what is appropriate to yourselves,” stressed Bohan. “The thing is to look at process before you automate; if you don’t optimize [your current process] first, all you do is produce waste and you can lose money quick that way. Look at your business, at what is driving it, and then ask ‘where should I first put in automation’—and the answer depends on your business. Sometimes it’s prepress, sometimes it’s in the press room, other times it’s on the customer side.”

Once a shop has optimized as far as it can on its own, and is ready to bring in automation solutions, the questions is what to look for. First and foremost, noted Wengenroth, it’s important to make sure whatever solution is chosen, it will play well with all the rest of the equipment and solutions the shop is already running. “The most important thing is that a solution be open, flexible and scalable,” she said. “Business requirements change rapidly, and an automation solution should not lock a printer into a specific press, workflow or vendor. Ultimately there are many different processes and systems that come into play from when a order comes into a shop until it’s produced, shipped and billed. Being able to tie systems together and have them communicate with each other is essential. A system needs to evolve and change as a printer’s business changes – whether they add a new press, new finishing, or a new customer.

Viniski agreed, noting, “Most printers don’t have dedicated IT or software engineering resources. So the key factors for them to consider when evaluating automation or any workflow solution becomes operability and integration. The days of feature face-off are quickly becoming less relevant—what’s important today is the ease in which a solution can be installed, operated and integrated with other systems in their shop.”

But making sure the solution is flexible isn’t the only issue. Printers need to make sure their staff is ready and willing to change as well. “Before making a purchasing decision on a new workflow automation product, there are plenty of things to consider, not only about the software itself but also your own print shop and staff.” His questions to ask include, “Are you committed to making a change and is your team willing to change and put in the time required? What are your core, got-to-have-them, can’t-live-without-them, must-have requirements? How long does it take to get up and running? Is training included or extra?”

Other factors to consider when choosing a solution include whether it is hosted in the close, as a software-as-a-service (SAAS) solution, or whether you will be required to host it on-site, using your own servers. Both types have their pros and cons, although more solutions seem to be moving toward SAAS because they are easier to upgrade and add features and functionality to, and because it removes the need to have dedicated IT staff for the solution, as the solution provider takes care of it from their end.

At the end of the day most printers, whether they realize it or not, already have some form of print automation in place, usually on the front-end or in prepress. But while more comprehensive automation solutions have thus far been relegated to the larger shops, one of the biggest trends for the next few years will be both the expansion of automation into more points of the shop, as well as moving into the small and mid-sized shops.

But it is important to remember, Bohan said, that there is “no one-size-fits-all solution. There is no golden bullet.” Automation won’t magically improve business, it will only enhance and streamline what you already have, making the work easier and more profitable in the long term. But a solution that works great for the shop down the street might fail miserably in another, so printers can’t go in expecting to just automate and everything will work out. Print automation is the way our industry is moving, and the shops that understand their own workflows—no matter how big the shop is—and know how to best use technology to improve their processes, will be the ones to watch.