It’s All in the Visualization

Whether custom or template-based, today’s software is dedicated to making packaging design faster, easier, and more profitable.

If you’re looking to add packaging into your service mix, today’s software makes it faster, easier, and more profitable.

Before making the leap, however, the first question to consider is whether you want to play in the print-only space. In this space, your expertise will extend largely to putting ink on a substrate. Like commercial printing, production-only packaging is a commodity market. If you go this route, you will end up competing on price. As Esko’s Jan DeRoeck, director of solutions management for Esko, said, “There are no winners in a price fight.”

If printers want better margins, they need to go deeper into the process. That means understanding how the package will be not only printed but filled, warehoused, distributed through the logistics chain, placed on the retail shelf, and ultimately be used in at the end location, and how all that impacts the design, substrate, and ink choices.

This is very different from the world of brochures, magazines, direct mail, and collateral that most commercial printers are used to. It also implies changes to the business model and how you deal with your brand customer.

While there will always be a human aspect to designing a three-dimensional project like packaging, there is software that helps with making the process faster, more streamlined, and with less likelihood for error.

3D Proofs and Other Time Savers

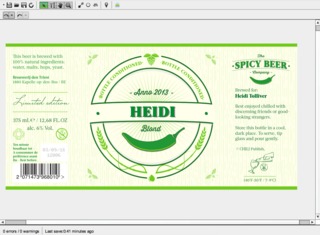

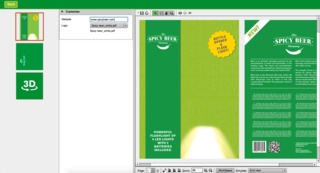

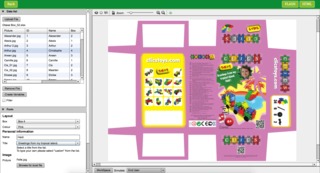

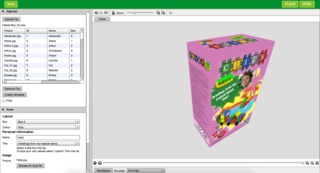

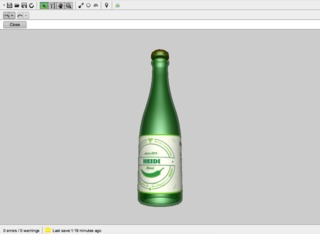

One of the innovations adopted by many packaging software companies is the ability of PSPs and their clients to see their layouts in 3D. They can view how the text, images, and graphics line appear once the package is assembled. Using animation, users can rotate and manipulate the package (which is very helpful when text and graphics are placed upside-down and sideways from a front “flat” perspective) and even open and close flaps and closures. They can make changes and immediately see how that affects the final product.

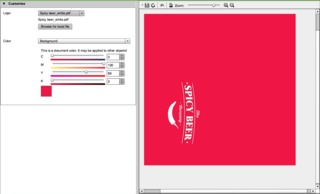

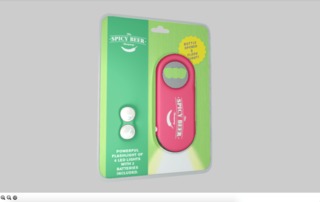

CHILI Publish is among those offering 3D tools and animation. Among the “extras” to minimize error, especially for non-technical users, is a help layer with help lines for positioning text and fold lines. When the user is ready, the 3D animation lets them view the package as it will look once printed, folded, and ready to be filled.

Bram Verniest, owner of CHILI Publish, gave the example of a flashlight being sold in a cardboard-backed package with a protective plastic cover. “Say you have promotional text in a starburst and want to enlarge it, shrink it, or move it over .5”,” he said. “What affect does that have on the overall design? Does it the change interfere with other elements? 3D proofs let you see the impact immediately.”

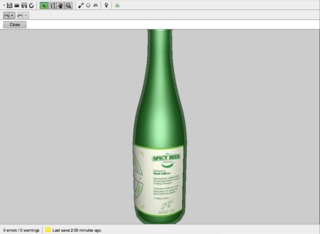

The more complex the package, the more helpful 3D tools become. Esko’s De Roeck gave the example of a shrink-wrapped bottle. When the packaging is shrunk, it distorts the printed shape. “Traditionally, designers have placed a printed sleeve around a bottle, placed grids on it, put it through a shrink machine, measured the distortion, and used those measurements to figure out how to compensate for the distortion,” he said. “By using virtual 3D graphics and CAD design, you can literally save weeks of time.”

Some products, including Esko’s Store Visualizer, not only create online proofs of packages in 3D but show the packages sitting on the store shelf next to competitive products.

Other time savers include content management to streamline the process for packages managed by government regulation, such as labels in the pharmaceutical industry. “They have ingredients, dosage, that have to be up to date and 100 percent correct,” said De Roeck. “Esko's SmartNames module allows you to get into the brand owner's database, only where the copy is, and knows to pick up the copy and other elements automatically. It is automatically placed where it belongs, in the correct typeface, color and font size.”

De Roeck pointed to other critical software packaging tools such as the ability to automate the process of step and repeat on a press sheet. “That is a fundamentally different process compared to imposition software used to impose individual sheets onto a print sheet,” he said. “Step and repeat comes with intricacies like the length of the die cut tool. Hopefully you are using the same data to step and repeat for the die cuts. Esko has developed plug-ins to guarantee that alignment.”

Better Business Models

The level of automation provided by today’s software has vastly expanded the business model options for label and packaging printers. They range from scaling up volume to making it possible to target niche markets to opening e-commerce storefronts for small businesses to enable larger companies to produce short-run packages for test marketing.

One of CHILI Publish’s customers, FoldedColor.com, is built around the storefront model. Once the basic templates are set up, customers can go into their portals and customize their boxes as needed. They can change colors, graphics, and text to make changes, add new product lines, or create similar ones. 3D animation makes proofing quick and easy. By restricting the editing areas, FoldedColor can offer fast turnarounds (FoldedColor.com advertises shipping in five to seven business days) and prevents design mistakes.

“Say they want to change the package from blueberry ice cream to raspberry,” said CHILI’s Verniest. “You can swap out images, text, and graphics. The solution offers a lot of design freedom, and it is up to the printer to determine the amount of freedom they provide.”

CHILI Publish is available as a standalone solution or as a plug-in for the variety of e-commerce, MIS, DAM, and workflow solutions from companies like Esko, Enfocus, XMPie, Xeikon, Xerox, North Plains, EFI, and DALIM Software. Custom packaging can be created online using the online editor or offline using Adobe Illustrator.

Making Color-Critical

Another difference printers will find moving into packaging is the need to manage brand and spot colors as a default expectation. There is a distinct challenge in ensuring color consistency across the complete set of packaging materials and printing processes.

“Without a reliable way of simulating what happens to the brand color inks on the wide range of substrates, a color management system doesn’t offer all the necessary information to accurately predict brand colors,” noted Esko’s DeRoeck. “The same goes for figuring out how process inks will interact with spot colors. Or what the impact will be in changing to another print process last minute.”

Once again, software is there to help. In combination with Esko’s color database, Esko’s Color Engine, for example, facilitates the creation and maintaining of critical brand colors, spot color profiles, and other color conversion settings. This maintains consistency from end to end by ensuring all applications and operators work with the same color data.

Products like Esko’s Equinox and FlexProofE and a product co-developed by Square SA and DALIM Software, PDF PerfectPreview, address the unique needs of package proofing and expanded gamut workflows.

Also unique to packaging is the heavy use of metallics. In traditional workflows, it can take hours to apply white ink masks to create effects. Products such as Color-Logic’s Design Suite vastly simplify and speed the process by eliminating the need for masks. Printers can create metallic effects using five colors (CMYK plus silver or CMYK plus white if printing on a metallic substrate) in minutes. Color-Logic recently created a real-time video of the application of metallic effects to 24 tags in nine minutes.

Deeper Workflow Integration

For printers who want to have deeper workflow integration with their customers, DALIM Software offers full workflow solutions. “Where we are investing more effort today is for the ability of PSPs to be better linked in the brands and retailers in collaborating and communication around packaging print pieces,” said Graham Blanks, director of business operations, North America, for DALIM Software. “We provide a platform for uploading and sharing content, then managing it across all the stake holders, from production to creative to marketing and legal. Everyone can get eyes on the project, make comments, and give approvals before the file is finally sent out to print.”

Twenty years ago, DALIM Software launched its automated workflow product, DALIM TWIST. Today DALIM ES has moved upstream to serve as a single point of contact for project sharing and collaboration. Its DIALOGUE Engine allows annotation and markup of 3D models, as well as video within a single platform.

This is a big change from pushing around hard copy files between different systems. “If clients were emailing files, they were asking, ‘Who had the file last?’” said Blanks. “DALIM ES and DALIM DIALOGUE Engine bring all that together under one roof and really add value for PSPs identifying their need to become marketing service providers.”

In fact, after adoption of the Dialogue engine, DALIM Software has found customers that have been able to reduce approval time from weeks to days.

Dialogue also provides the ability to visualize and manage layers and inks within a printed piece.

What are the most significant update to DALIM’s products? According to Blanks, the ability to visualize 3D objects in very simple and easy way and annotation tools directly attached to the objects. “This is done within a standard web browser in HTML 5,” he said. “It also provides side by side comparisons and overlay between changes in a 3D object. If you have a labeled bottle, with a label on the back and front, you can turn the visualization around. If someone has annotated the back label rather than the front label, you want to make sure the annotations are attached to the right area.”

For printers looking to get into packaging, advances in software abound, speed the process, eliminating error, and better managing the collaborative process. To succeed in packaging, PSPs should value not only their investment of the press, but the technology that supports the workflow, as well.