No More Secret Sauce: The New Role of Estimating

New pieces of equipment and new technologies affect the ability to estimate jobs efficiently, so how do we estimate today?

There was a time when it seemed like estimating a print job was one of the occult arts, a plant’s estimator being a kind of Delphic oracle who, when presented with an RFQ, would go into a trance and, some time later, reveal the number to be passed on to the potential customer. It was an estimate based on experience, with no small amount of “secret sauce.”

While this approach to estimating may have stood shops in good stead back in the day (and perhaps for some still), it fails to take into account 21st-century realities. Today, there is far more to estimating than simply deriving a number.

I quote, therefore I am

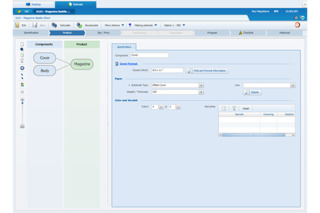

“It used to be that you called in an RFQ, the sales guy would pick it up, call in or get back to the office later that day or the next day, and get back to the customer in a day or so,” said Nick Benkovich, senior director, Portfolio Product Management at EFI. “That’s gone. If you take a couple of hours to get back to a customer with a quote, they’ve already found someone else and the job may be in production by then.” EFI’s iQuote is a visual, cloud-based smart estimating system that supports current and emerging print technologies.

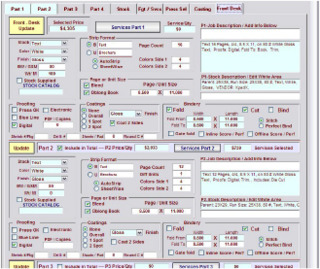

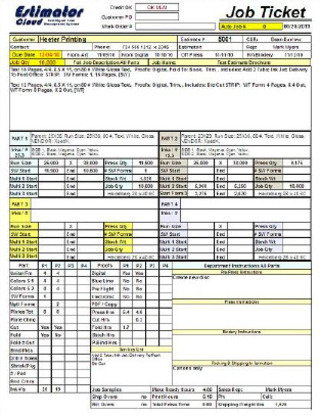

“He who estimates first, wins 15% more business,” said Mark Myers, president and CEO of EstimatorCorp. Launched in 1995, EstimatorCorp’s Estimator Plus-WF is an MIS and estimating system that boasts a simple, one-screen interface that allows virtually instantaneous estimates for any print technology, from sheetfed offset to digital wide format. The latest version is Estimator Cloud.

Shops recognize that the way they estimate jobs and generate quotes needs to change. In a new PRIMIR report, North American MIS/ERP Adoption in Commercial Printing, researchers David Zwang and Cary Sherburne found that estimating was identified as the top production bottleneck, and yet estimating was only the third most-used MIS system component.

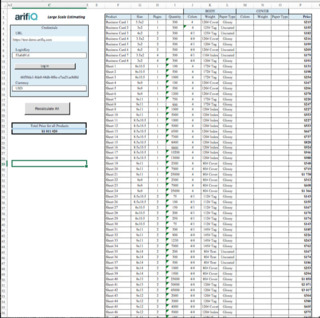

“There’s a lot of time and money to be saved if you cut down the time spent estimating, quoting, and doing order entry,” said Eva Rosen, co-founder and executive chairman of ArifiQ. “If you let your customer do it, you can cut your time down to zero.” ArifiQ provides quick estimates and optimized workflows. ArifiQ’s proprietary algorithms analyze up to one septillion combinations of resources and cost variables to arrive at a quote, including presses, paper, and finishing, as well as hourly rates, discounts, and profit margins. The company also recently announced a Large Scale Estimating module that can generate hundreds or thousands of estimates in only a few minutes.

There is the desire on the part of a growing number of print buyers to make buying print identical to any other kind of ecommerce transaction: go to a website, plug in specs, find out how much it’s going to cost, and order it, all without having to interact with a human. “The printing industry has to adjust to how we buy other things,” said Rosen. “When you have a fast response, you don’t go home with quotes, you go home with orders. The customer often wants to do business as fast as possible.”

There is another pressing reason to automate estimating. “The skills of estimators have started to disappear in our industry,” said Benkovich. As experienced estimators retire, he said, “that tribal knowledge has to be maintained in the business.”

“There are fewer people who understand the complete printing process,” said Myers. “And less and less people who understand the estimating process from a printing perspective.”

At the same time, new pieces of equipment and new technologies affect the ability to estimate jobs efficiently. As shops move away from traditional offset, or add products and services far afield of the kinds of jobs they are used to—like wide-format printing—that also has a strong impact on the estimating needs of the business. “People are adding special varnishes, die-cutting, and all sorts of fancy things to make print more relevant, more exciting, and more engaging,” said Benkovich. “So, we have to build a system that really takes into account all those things.”

“More and more and more of our customers have added large- and grand-format to the products that they offer, so the estimating software really needs to be able to effectively estimate offset, digital, and large-format,” said Patrick Bolan, president and CEO of Avanti. “How do you get one estimating system to estimate all three of those disciplines?” Avanti Slingshot, the company’s from-the-ground-up print MIS, was built in part to take into account those three types of jobs.

The aim, then, is to begin estimating process at the end of the production process and work backwards. That is, start with the final product and describe it to the estimating system. Say you’re printing a book. The interior will be 128 pages, black-and-white, on stock A, and the cover will be five colors on stock B. It will be perfect bound, and the run length is 500 copies.

“The system tells you, based on every piece of equipment you’ve got in your shop, the most effective way of calculating that,” said Benkovich, “You don’t need to know how that magic happens.” And the system does this by determining—also based on all the capabilities the shop has—what the best way of producing that job will be.

Avanti Slingshot is likewise based on estimating from the description of a final product. All the details of how to create a job—the tasks that are going to be part of it, the press it’s going to run on, the imposition—are pre-built into a work template. “The CSR doesn’t even see all that,” said Bolan. “He/she just sees the work template for, say, a six-page brochure. He/she pulls that up and it’s all filled in for them automatically.”

When Myers developed EstimatorCorp’s estimating software, he began with a basic formula. “There wasn’t going to be a plate on a press unless you did everything that comes before that point,” he said. So the goal is to enumerate all those tasks—and the materials those tasks require—that lead up to putting a plate on press. And then, of course, the processes that happen after that point.

“We are increasingly seeing demand for a true, end-to-end print management solution, with a robust MIS platform at its core,” noted Tony Tarpey, COO of SmartSoft. “This has always been the philosophy with PressWise—to create a platform that not only contained the tools typically found in a traditional MIS system, but to build that out in a way that focuses on workflow automation with minimal touchpoints. This includes integrations with most major web storefront platforms, asset management, automatic impositioning, gang run print optimization, mail processing, and more. These were all silo processes before and tremendous ROI has been achieved by bringing them into PressWise and making them native system functions.”

“I have a cunning plan...”

What has now become an essential part of estimating, or the software that is used for estimating, is generating not just a price, but a whole production plan. “If you get the estimate wrong, everything goes wrong from that point on,” said Benkovich. “If you get the estimate right, the job plan flows. You have to be able to see all those steps.”

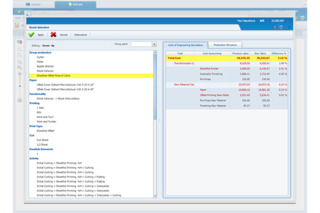

“ArifiQ calculates every possible production path,” said Rosen. The system then presents different production options, identifying the most efficient based on press availability. The system will even tell you whether a job is better run offset or digital—sometimes counterintuitively. “You don’t need to select the print method, they just type in the specs and ArifiQ will determine that. Often, they have already decided before estimating if they should run it digital or offset, but then they’ll be puzzled by what ArifiQ says. They’ll ask, ‘Is digital really the best option for this job?’”

“We have to get to the point where the customer can describe to a sales person, in a very simple way, the print product they want and we, under the hood, magically generate a price and a production plan,” said Benkovich.

However, that production plan may have to change on-the-fly. For example, despite many customers’ demands for fast-turn jobs, it sometimes—perhaps even often—happens that there is a lag time from when the estimate was produced and when the customer finally submits the job. In this case, the press on which the quote was based may not be available, or some other aspect of the production may be different. The downside to this is that it may end up costing more to run the job than had been estimated, which means that the job could lose the company money.

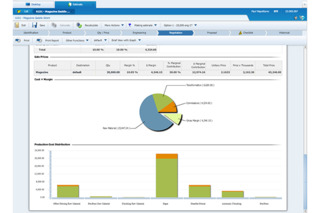

Myers’ approach has been to treat each piece of equipment independently. “You can add on a different profit margin for each piece of equipment,” he said. “You can see the total profit on each job and refine it even further to determine the profit on each piece of equipment.”

It’s not just a changing equipment mix that estimating software needs to keep up with, but other kinds of related services, as well. “Customers are getting into fulfillment,” said Bolan, “and you have to put that on the quote.” Fulfillment—say, kitting—often includes a mix of production processes. “Maybe one item is offset, one is print-on-demand digital, one is wide-format, and one is promotion.” Say, for example, a print customer is doing corporate training. “Maybe they want a teacher’s book that is offset, the student books are digital, there are some banners and wide-format graphics, and a few promotional items to give away,” said Bolan. “So you start to see multiple disciplines on a single quotation.”

Tarpey notes that PressWise continues to innovate in ways to reduce touches and provide a true end-to-end MIS platform. “Recent launches include a Full Service Mailing Module within PressWise, integrated Purchase Orders to streamline the outsourcing process, new support for Work and Tumble impositions, and new integrated shipping tools for all the major shipping carriers,” he explained.

There has to be a morning after

It’s important to gather shop floor data and compare the final production costs to the estimate, as sort of a post-mortem, to verify—in real time—that jobs are making money, or at least not losing money. “They need to see how much variation there is among the estimate, the production plan, and reality,” said Benkovich. After examining these data, he added, “they may say, ‘This is just not a profitable product for us.’” These data can then be used to discontinue certain products, or guide investments in new equipment. With iQuote, Benkovich said, users can generate different scenarios. “Say I bought a new Landa press,” he said. “I can feed in all the specs from my jobs in the last 30 days, and see what my production would have looked like if I ran it on the Landa press. It helps you make the decision about investments.”

Estimating today is part of a much larger ecosystem that is intricately connected with the company’s MIS, and plays a role not just in instantly quoting prices, but analyzing shop floor data and determining in real time the profitability of specific jobs and even pieces of equipment. And yet, as the PRIMIR study cited earlier discovered, gathering and using shop floor data is the least used of any MIS component.

As more and more shops add new equipment, and even new products and services like wide-format printing—and all the ancillary finishing and installation tasks they may require—estimating systems need to be as flexible and configurable as possible, while at the same time being easy to use. “They need the ability for people without traditional training in printing to be able to do estimates,” said Myers.

Everyone’s doing it

Shop owners need to change their mindset. “People don’t like to have their knowledge put into a system so that then everyone can do estimating,” said Rosen, “but that’s the way it has to be. It’s not the printer who sets the agenda, it’s the customer. If they are used to getting pricing and placing orders online in a very fast and transparent way, print will seem like an old technology.”

It can thus drive people away from wanting to print at all. And haven’t we had enough of that already?