Embellishments: What’s Old Is New Again and Still Adds Value! — Part 1

Embellishment has been a function of print production for as long as there has been printing. In fact, it almost goes back to the beginning of the writing of documents. There is no doubt that embellishment does add value to the printed product.

Embellishment has been a function of print production for as long as there has been printing. In fact, it almost goes back to the beginning of the writing of documents. There is no doubt that embellishment does add value to the printed product. Especially with the more recent introduction of digital embellishment technologies, designed to complement digital printing technologies. New developments in digital embellishment are happening all the time now that it has finally begun to capture market awareness. In part one of this two-part feature, David Zwang will look at the added value and long history of embellishments.

Story by David Zwang

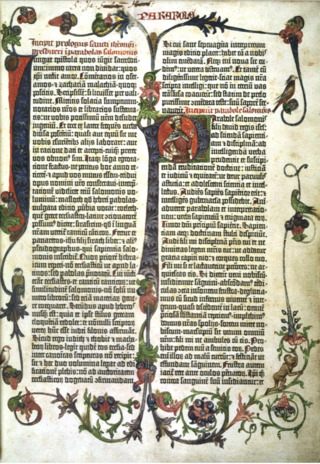

Embellishment has been a function of print production for as long as there has been printing. In fact, it almost goes back to the beginning of the writing of documents. The process of embellishment has also been known as “illumination” and can be traced back to religious texts before the first century. The process, at that time, included adding silver and gold to both text and images to illume the content. While we may not think of color printing as embellishment, color was also used to bring attention and additional value to documents for thousands of years as well. Of course, embellishment and even “printing,” at that point was done by hand using colored dyes and inks in a very tedious process.

Enter technology. Depending on which side of the discussion you sit, printing (or producing multiple copies from a master) was either invented by the Chinese around the 1st century or the Germans in the 14th–15th century. In either case, embellishment was still a fairly manual process. By this point changing or adding color through the use of “multiple impressions” or plates was possible, but the use of gold and silver was still a manual process.

Hot foil stamping, which uses a painted carrier sheet which when hot stamped with a die (plate) impressed on the receiving media was first believed to be used in the 19th century. These carrier sheets are coated with different colors including metallics, a release layer, and an adhesive. At this point it was used for book printing, primarily covers, but as the availability became wider, so did adoption. The introduction of cold foil printing or stamping in the 20th century made it even easier. In this process, an adhesive is printed using a normal printing plate or cylinder and the coated carrier comes in contact with the adhesive and the metallic coating is pulled off the carrier and remains on the substrate.

Another form of embellishment requires the manipulation of the substrate. Examples would be embossing, debossing, and decorative die-cutting. In the case of embossing and debossing, a “die” and a mirror image “counter” is used to put specific pressure on the substrate in order to create a visual representation of the die “in” the substrate instead of “on” the substrate like the foils or inks. Finally, we have decorative die-cutting, which could be as simple as a window in a page to see through. This type of die-cutting uses a similar principal to embossing and debossing in that there is a die and a counter, the difference being that with die-cutting you are usually cutting through the substrate and not just making an impression in the substrate. Of course, die-cutting has other functions as well, like creating the shapes necessary to construct packaging or other dimensional structures.

There is no doubt that embellishment does add value to the printed product, especially with the more recent introduction of digital embellishment technologies designed to complement digital printing technologies. According to a Keypoint Intelligence-InfoTrends study Beyond CMYK: The Use of Special Effects in Digital Printing, print enhancement volume will grow at a CAGR of 27% through 2020. Profit margins on digital print enhancement range from 50% to 400%, and importantly print buyers will pay a premium of 24% to 89% over CMYK for print enhancements. So why isn’t it more widely used? Until the introduction of digital embellishment technologies, the reasons embellishment hasn’t reached the level of adoption that it could—or even should—are limitations in experience, equipment availability, and operational costs. Specialized companies, which use their experience and amortize their equipment across many customers and incoming jobs, were—and still are—used as an outside service to add these embellishments to a printer’s products. Unlike commercial printing presses, flexo presses have supported foil, embossing, and decorative die-cutting embellishment inline for years. It is only logical since they are used for label and packaging production, where brandowners are always looking for a way to increase their shelf appeal.

Digital embellishment technologies have now been introduced to replace most of those analog solutions and in many different configurations designed to make it easy to implement in your own facility. It is timelier and more cost-effective as well, since you no longer need to create physical plates and dies, instead using digital print technology like toners and inkjet heads. The primary technologies used in digital embellishment are varnish deposition usually using inkjet printheads or clear polymers using the electrophotographic processes; high-build polymer dispersion cured with UV; metallic foils; metallic “nano” particles in a varnish or polymer suspension; UV-curable resin for creasing/embossing; lasers for die-cutting, and various combinations of all of the above. This has also opened up the possibilities of using embellishments on a more regular basis.

Whether it is all about design enhancement or security, the needs for embellishment today isn’t that different than what it was in the 1st century, adding awareness and value to content. In part two, we will take a look at the new tools for embellishment add value to print and packaging production.

More to Come…

I would like to address your interests and concerns in future articles as it relates to the manufacturing of Print, Packaging and Labels, and how if at all it drives Industry 4.0. If you have any interesting examples of hybrid and bespoke manufacturing, I am anxious to hear about them. Please feel free to contact me at [email protected] with any questions, suggestions or examples of interesting applications.