Finishing Starts at the Beginning: Design with Specialty Finishing in Mind Is Critical

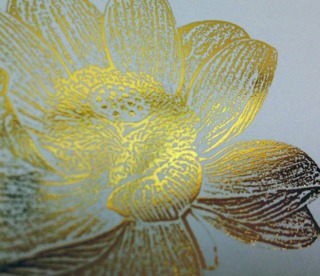

Taking advantage of die-cutting, embossing, foil stamping, and other “high-visibility enhancements” allows printed materials to stand out.

Over the past several years, we’ve been seeing a renewed interest in, and the growth of, specialty finishing processes that go beyond simple cutting, folding, or perforating. Taking advantage of die-cutting, embossing, foil stamping, and other “high-visibility enhancements” allows printed materials to stand out in a cluttered mailbox—and even help print compete with electronic media. For these products to have the intended impact, however, the process needs to start at the very beginning—with print customers’ customers.

First, though: just what are these products and their impact?

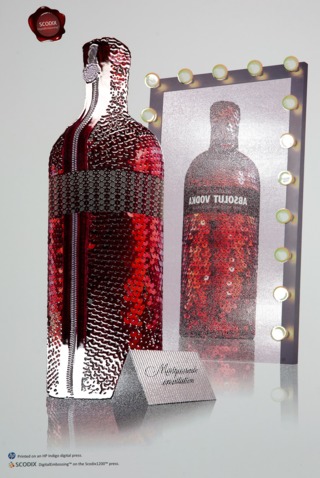

“Imagine getting a bottle of perfume in a gift box, and on that gift box you have the Dior box embossed in 3D and your girlfriend’s or wife’s name embossed in foil,” said Kevin Abergel, VP of Sales and Marketing for MGI. “The whole idea is that now that we’re able to customize embossed foil, she would never throw that box away. You make the packaging more valuable than the actual contents.”

MGI offers a variety of digital printing and finishing systems, including the JETvarnish 3D, which applies both flat and raised spot UV coatings as well as iFoil, which runs inline with the JETvarnish 3D to add digital embossing and hot foil stamping.

The “Share a Coke” personalized bottle campaign a couple years back is perhaps the emblematic example of this idea. The packaging becomes a collector’s item.

But even without going that extra personalized mile—and the Coke campaign was limited to only some of the most common American forenames—adding specialty finishing effects can make printed pieces, like packaging, stand out on a crowded store shelf.

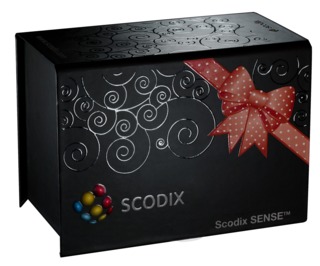

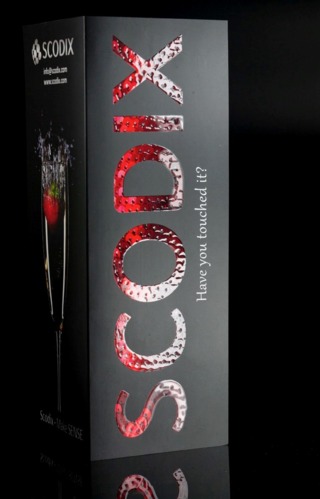

“Grabbing customer attention is a challenge, and this challenge is going to grow as the consumer is engrossed with more and more data, visual information, and messages,” said Amit Shvartz, Vice President of Marketing for Scodix. Scodix’s digital finishing enhancements add a tactile third dimension to printing, “making print an experience,” said Shvartz. “Research shows that it grows customer attention by a factor of 10. Just like black-and-white was replaced by color, today CMYK is not enough. Enhancements are the new trend, and the consumer is expecting enhancements.”

Fixing Fixation

More and more research is quantifying the impact of specialty finishing processes and high-visibility enhancements. One recent study sought to measure the extent to which foil-stamped packaging attracted the attention of shoppers and potentially influenced buying behaviors.

According to the Foil & Specialty Effects Association (FSEA), which commissioned the study, only about 10 percent of printed products feature some kind of high-visibility enhancement like foil stamping. The typical case studies, usually provided by brand owners, express the impact of specialty finishing in terms of increased response rates or, in the case of packaging, increased sales of a particular item. For example, Best Choice Private Label Products reported that after it added gold foil stamping to its olive oil packaging, retailers saw a 30-percent “jump in velocity” for the brand and retention of 10 to 15 percent thereafter”. (“An Initial Study into the Impact of High-Visibility Enhancements on Shelf Presence,” Foil & Specialty Effects Association, 2014.)

Sales can be influenced by a lot of things, and without knowing what other advertising and promotion initiatives may have contributed to increased sales an controlling for them, the quantification of the effect of specialty finishing on packaging is largely conjectural.

To gain a better sense of this, the Sonoco Institute of Packaging Design and Graphics at Clemson University conducted a unique study—developed with the FSEA—in the CUshop Consumer Behavior Lab. The study included 265 subjects who participated in the experiment for three days. They were required to don a pair of Tobii Glasses, which have sensors to track eye movements as well as a forward-facing camera to capture what the subject is specifically looking at. The subjects were then sent into the CUshop armed with a shopping list, which consisted of a randomized list of items. They were instructed to shop the way they normally would. Infrared (IR) markers were used to help track what products on a shelf the subjects specifically fixated on. Researchers could then determine how long it took subjects to “find” a given product on the shelf (identified as the “time to first fixation”) as well as how long they looked at that product once they found it (called “fixation duration”).

When a product’s package featured foil stamping, the mean time to first fixation was two seconds, compared to just over 3.5 seconds when a package was unadorned with foil. And foil-stamped packages produced a mean total fixation duration of just under two seconds, compared to just over 1.5 seconds for non-foil packages.

Concluded the researchers, “There are clear advantages to foil stamping on packaging, in terms of attracting attention faster and retaining attention longer than identical packages without foil stamping.”

However, they caution, “it is also the hypothesis of the research team that foil stamping increases sales, but this will need to be quantified through a study specific to tracking sales.”

The Long and Short of It

That all being said, the past couple of decades have seen reams of market research studies demonstrating the effectiveness of customization and personalization, aided and abetted by digital printing. Specialty finishing systems are moving to accommodate personalization, as well as the related trend toward declining run lengths.

“Run lengths are becoming shorter for packaging, greeting cards, invitations, and novelty pieces,” said Bob Flinn, Director of Business Development for Standard Finishing Systems.

Standard Finishing recently introduced the Horizon RD-4055 die-cutter, designed for digitally printed materials, and has a maximum sheet size of 15.74 x 21.65 inches. Rather than requiring a craftsman’s knowledge about how to create dies, the RD-4055 uses flexible die plates produced by third-party die makers. A user creates a PDF vector file of the item the die will be cutting—a box, a door hanger, or other object—and uploads it to any of a variety of diemakers (Kocher+Beck, Rotometrix, Electro Optic, and Wink are four that Standard Finishing customers work with) and they can usually turn a die around in 24 hours. The die plates can often run for a million or more impressions—not necessarily long runs, but many short runs. The cost of a die is between $150 and $200.

“A lot of people are doing door hangers,” said Flinn, “five different door hanger designs. The cost to make up the die is pretty inexpensive, and they can use that same die for many many jobs and sell that same layout to numerous customers.”

The ease of use also means that anyone can be trained to use the RD-4055 in a very short period of time. “We can train an operator and have him up and running in one-day of training,” said Flinn.

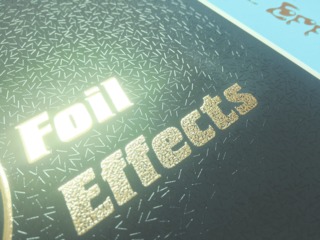

Like die-cutting, traditional foil stamping is an art and a craft that has been simplified thanks to new technology.

“When it comes to embossed foiling, it’s voodoo, it’s a black art,” said Abergel. “You need someone who has a lot of experience running those machines. We’re democratizing that kind of finishing, where you don’t need 10 years of experience. We’re going to make embossed foiling available to the average printer to enable them to bring it in house.”

The Beginning of the End

Operating the equipment is one thing, but designing the pieces that will go on it is another, and that’s where the real education is needed: at the front end of the process.

“Our main focus going after the designers,” said Mike King, President and CEO of Eagle Systems. “A lot of people don’t put foil on their packaging because the people who sell to the end users don’t encourage it because they don’t do it. We’ve been going to the designers and educating them to what foil can do to jump off the shelf.”

Founded by King 25 years ago, Eagle Systems—aka The Foil Experts—is a developer and manufacturer of hot and cold foil enhancement equipment.

“The market is growing rapidly,” said King. “We’re getting a lot of name brands calling us asking us, ‘how do we cold foil, how do we do hot foil?’.”

Education at the front end of the process has become paramount.

“That’s really the issue we’ve had, getting people to design for [embossed foil],” said Abergel. “People were designing pieces that looked very boring because they weren’t taking advantage of what the relief and tactile effects could bring to you.”

As part of its educational efforts, MGI has developed a series of design guides that customers can rebrand and then give out to their own customers to get the creative juices flowing. One MGI customer, Northern Ohio Printing, hosts a weekly “lunch and learn” in which designers, agency personnel, and other print buyers come in for lunch and learn how to design with custom finishing in mind.

“Designers are the key,” concurs Scodix’s Shvartz. “One of our focused activities is to identify and educate the originators about the Scodix capabilities, and to make sure Scodix is part of every major job, especially early in the process.” Scodix has created a special function called Customer Business Development, which is focused on working with print service providers to reach the designers in their community and encourage them to use Scodix finishing processes. Customer Business Development efforts include free trainings, open houses, offering free jobs, sending samples, sharing activities in the designer’s organizations, and much more. “We expect this task to stay high on our priority list, as we are offering more and more enhancements and creative tools to this important community,” said Shvartz.

Opening New Packaging

Packaging prototyping is becoming a top application for digital printing, and for digital finishing, which for some MGI customers has become part of the design process itself, and they have created interactive “labs”—replete with printing and finishing equipment, big-screen TVs and wet bars—where brand owners or ad men can experiment with different substrates and foils. “In the space of two or three hours, they’ll try maybe 100 different die designs with maybe 30 different types of foils,” said Abergel. “They’re going to walk away with 100 different prototypes. That would have taken them two months to do traditionally and it only costs them two or three thousand dollars instead of something exorbitant.” Don Draper, eat your heart out.

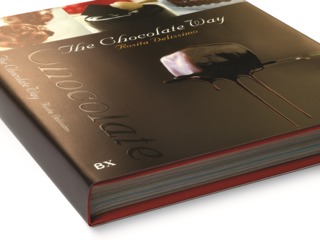

Specialty finishing processes are penetrating into more and more segments of the printing industry, such as direct mail, where personalization and specialty finishing can provide a one-two punch to catch a mail recipient’s attention. Other items like brochures, photobooks, business cards, and much more are also ripe for enhanced finishing. Special effects in book printing, specifically book cover printing, are also growing rapidly.

“The book market is huge especially now that you have the book printing on demand, books of one, and self-publishing,” said Abergel.

Foil and die-cut effects have long been a hallmark of greeting cards, as it were, and now card producers can produce shorter-run, digitally created, personalized greetings cards, for when you care to send the very best, and the very best personalized.

And if those greeting cards are going into the mail: “We even saw mail stamps being made with Scodix,” said Shvartz. “We see many applications coming from the web-to-print arena, where digital enhancement is the only way to deal with enhancements in the run length of one.”

Wrapping It Up

Adding equipment and getting up to speed are only part of the equation. Education and outreach comprise the other part. Taking full advantage of what today’s specialty finishing equipment can do starts with the design itself, and creating these “high-visibility enhancements” is a collaborative, creative effort between print service providers and their customers.