10 Years Later & Stronger Than Ever: JDF Facilitates Printing Plant 'Communication'

Love it or not, JDF is the only standards-based approach to integration available for a printing industry bent on achieving ever-greater levels of automation.

New technologies keep early adopters on the bleeding edge, but 10 years of development brings the expectation that all the kinks have been worked out. That’s the case for version 1.4a of the Job Description Format (JDF) electronic job ticket specification; this latest update to the decade-old specification was published in December 2009 but is just now being implemented by a variety of vendors.

Compatibility with this maturing technology has been certified for 50 different applications, with the latest addition (as of press time) being Avanti’s Graphic Arts Management System V12.2. According to the Printing Industries of America, administrator of the JDF certification process, Avanti’s MIS application can share data with prepress workflow systems “using Job Messaging Format (JMF) communications, while transferring the appropriate JDF requirements for prepress workflow completion.”

The concept behind the acronyms has been a hot topic ever since computers arrived in printshops during the 1980s: allowing systems from different vendors to communicate job ticket and machine setup information using a common terminology. Today, most MIS and prepress vendors have implemented both the JDF job ticket and the JMF communication protocol (for sending and receiving job information, including machine status info such as device speed and run counts), joined by an ever-expanding list of finishing equipment vendors and press manufacturers.

A History Lesson

That wasn’t always the case, however. Soon after the “Gang of Four” (Adobe, Agfa, Heidelberg, and MAN Roland) announced their intent to create an XML-based job ticket architecture at the Seybold Boston 2000 tradeshow, skeptics began to emerge from the woodwork. Criticisms that version 1.0 of the JDF specification was too vague, and that too much work was required to create cross-vendor implementations missed the point: by basing JDF (and JMF) on the popular eXtensible Markup Language (XML), the Gang of Four was embracing a new approach in which user-developed extensions to the protocol would not only be admissible, but encouraged.

Shortly after the JDF effort was announced, guidance of the nascent specification was turned over to the International Cooperation for the Integration of Processes in Prepress, Press, and Postpress (better known as CIP4), a non-profit organization dedicated to the development of printing industry standards. Having already developed the Print Production Format widely used to communicate sheetfed press ink key presets, the CIP4 committee was able to coordinate compatibility between JDF and the printing industry’s previous efforts at computer integrated manufacturing including PPF, PJTF (Adobe’s Portable Job Ticket Format), PrintTalk, IFRAtrack, and PPML (PODi’s XML-based Personalized Print Markup Language).

Germany’s 2004 Drupa festival saw the release of JDF version 1.2, as well as the debut of a first generation of JDF-enabled products from Adobe, Dalim, Enfocus, Global Graphics, Heidelberg, Océ, and others. While these first iterations were indeed focused on limited integrations between specific pairs of vendors, recent history has seen greater “plug-and-play” capabilities, thanks to the PIA certification program as well as the dedicated efforts of the CIP4 committee members.

“JDF is a very powerful tool, but the specifications are very complex and intricate for printing companies to implement,” noted Marcus Pabsch, manoland’s VP of product marketing for sheetfed printing systems. “JDF allows any printing company to put together the right production environment; [for example], our printnet software supports continuous automated workflow for publishing, advertising, and packaging printing production, networked modularly, based on open interfaces.”

Not every open interface is built around an industry standard such as JDF, however; some vendors simply publish their application programming interface (API) specifications and eschew JDF in favor of what has come to be known as “vendor XML.” These integrations may be less complex than JDF-compliant techniques but are only suited for connections between particular system pairings. Hammering out the interoperability of JDF may require more effort, but the result is a deeper integration across a broader pool of devices and vendors.

“People are slowly but surely automating, whether it’s silos or entire segments of their operation,” said Alex Hamilton, director of business development for Enfocus Software. “JDF support is one of those necessary checkboxes that you have to have today in order to claim that you’re a workflow automation application, like Switch or Prinergy or Dalim or EskoArtwork’s Automation Engine 10,” he explained. “Whether you use JDF or XML is a matter of user preference, but at the end of the day you’ve got to have that metadata if you’re going to automate your operations. To that end, Switch has an XSLT transform capability, which allows you to map one type of XML to another, or to JDF, allowing you to address any vendor-specific issues," Hamilton added.

Some Skeptics Hold Out

While JDF has certainly progressed since its uncertain introduction, still not everyone is sold on its value. "From my viewpoint, JDF is a solution in search of a problem," said Eric Pearson, president and CEO of commercial printing firm TechnaPrint in Eugene, OR. "We have expert operators who can configure our press and the bindery equipment very quickly thanks to the hardware’s programmability, so we don't need the added expense of a JDF interface for those devices. While we do use a very small segment of JDF functionality – ink key presets – I don't foresee a complete JDF implementation anytime soon."

Despite such misgivings about the cost of JDF for smaller companies, James Harvey, executive director of the CIP4 Committee, points to the rapid return on investment (ROI) experienced after JDF implementation according to self-reported data gathered as part of the CIP4 International Print Production Innovation (CIPPI) Awards Program. Harvey’s analysis of these case studies indicates that companies who invested in JDF integration saw an average annualized ROI of 277%.

“Smaller companies are more likely to get C-level buy-in for full automation, where the largest companies have much more complex approval processes to go through,” Harvey noted in a recently published report from the CIP4 Committee entitled What Print CEOs Need to Know About Automation. “Small and large printers were more likely to have moved to full integration, [which] dispels the myth that JDF-enabled automation isn’t for small printers.”

Given the growth in JDF/JMF adoption over the last decade, it seems clear that the early criticism did not kill JDF, but instead made it stronger. Love it or not, it’s the only standards-based approach to integration available for a printing industry bent on achieving ever-greater levels of automation.

SIDEBAR:

How Is JDF Used?

MIS – Estimates and reorders can be instantly converted into new projects, and planning details shared with prepress, pressroom, and finishing systems. Examples include Heidelberg Prinance and the DiMS! MIS System.

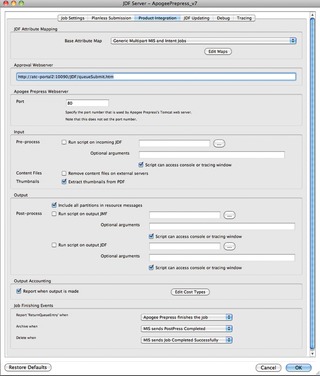

Prepress – Some printshops initiate their JDF efforts in the prepress department, where imposition templates and ink key presets can be generated in JDF format. Examples include Agfa :Apogee Prepress and Dynagram inpO2.

Pressroom – Conventional press consoles and digital press DFEs can both utilize JDF data, extracting customer information and run length from the MIS system along with imposition and ink coverage details from prepress. Examples include the Komori KHS-AI press console and EFI’s Fiery Print Server.

Finishing – The imposition data created in prepress can be shared with downstream devices such as programmable paper cutters as well as servo-driven folders, slitters, and perfect binders. Examples include POLAR Compucut and Muller Martini’s SigmaTrimmer.

Warehousing and Fulfillment – Users of JDF-compatible MIS systems can add a fulfillment module for controlling warehouse inventory and releases. Examples include EFI’s PrinterSite Fulfillment module and the Technique MIS Finished Goods Module.