Print Finishing Technology Roundup

There’s a lot going on in finishing so far this year, which is very exciting to see. There are big advancements in folding, book binding, cutting, coatings and more—so let’s just dive right in starting with my favorite category.

Folding

Stahlfolder TH 56 Miniature and Pharmaceutical Folder

For the first time, Stahl is bringing to market a solution focused primarily on pharmaceutical applications. The integration of an automated Stahl buckle plate folder, with at least eight plates in the first unit and eight in the second station, with a parallel knife unit and labeler reduces make-ready times from hours to minutes. The machine makes quick work of package inserts and outserts for the pharmaceutical and cosmetics industries while complying with all process monitoring standards.

Horizon AFV-56K Automated Folder

At the end of Q2 2021, Horizon will roll out their new AFV-56K Automated Folder featuring an impressive 44 automated settings for 20% faster changeovers. Enhanced production speed, safety and productivity, overhauled LCD touch screen with the ability to make fine adjustments, redesigned remote control and handling wheel provide easier operation and access. Like the BQ-500 Perfect Binder, the AFV-56K Folder also comes equipped with Horizon’s iCE LiNK cloud-based monitoring tool.

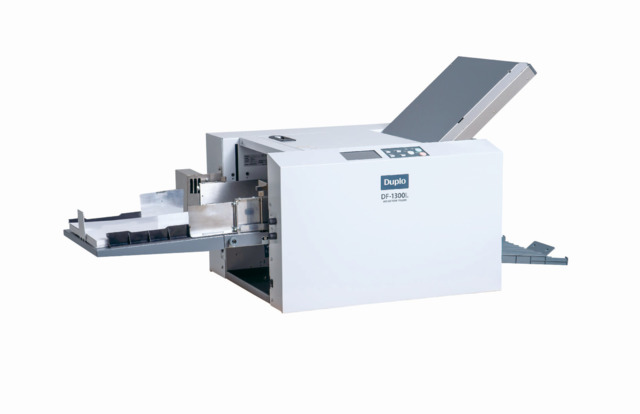

Duplo DF-1300L Tabletop Air-Suction Folder

Over 70% of users who are investing in Duplo’s digital finishing solutions are in the private sector, so they developed a quiet, user- and office-friendly, air-suction tabletop folder. The machine supports a 25.5" long sheet to achieve popular three-panel fold applications at speeds of up to 18,600 cycles per hour. An easy interface, pre-programmed folding styles, auto detection of standard paper sizes and automated setup round out the offering.

MBO K32-KSE Combi Anniversary Edition Folder

MBO is offering a special Anniversary edition K32-KSE folder that is packaged for the commercial print and book markets. The unit is specially configured to reduce make-ready, increase production rates, reduce labor and reduce material handling. According to MBO, this folder has the ability to replace old folding systems at two-one or three-to-one, and is available for a limited time thru August 2021.

Book Binding

Horizon BQ-500 Perfect Binder

The BQ-500 is designed for increased book-of-one productivity, automation and quality control over a wide range of substrates. The operator-friendly system can reach speeds of up to 800 books per hour—almost double the productivity of other binders in this range. The BQ-500 comes equipped with iCE LINK, a new cloud-based monitoring tool from Horizon that can also handle KPI analysis, PM schedule/alerts, JDF/JMF workflow, scheduling and more. The BQ-500 can be run in-line with the recently released HT-300 Three-Side Trimmer for seamless book production. In Q4 2021, Standard expects to release automated book block in-feeding, end sheet feeding and gauze feeding accessories for the machine.

Müller Martini Ventura MC Digital Thread Sewing Machine

Müller Martini’s Ventura MC Digital represents a revolution in digital book sewing because it enables the faster production of short-run, high-quality, highly customized books. Patented sewing technology plus a barcode-driven, touchless workflow eliminates make-readies. Integration of multiple processes—cutting, folding, collating, sewing, finishing—delivers seamless, trouble-free production for quality short-run thread-sewn digitally printed products.

Müller Martini Primera PRO Automated Saddle-Stitcher

The Primera PRO is an advanced and highly efficient saddle-stitcher for the mid-performance range, touting extra horsepower and faster speeds for medium and large runs. Advanced servo technology, innovative motion control and cycle speeds of up to 14,000 per hour, ensure a significant reduction in setup and throughput times for increased profitability. The intuitive system and fully automated features minimize the need for intensive operator training and manual intervention. Stitches up to 1/2” product thickness.

Duplo 150 Booklet System

Ideal for low to mid-volume runs, the 150 Booklet System offers an entry-level solution for print providers considering bringing their booklet making in-house. With a production speed of up to 2,400 booklets per hour, the 150 Booklet System performs saddle and corner/side stapling up to 25 sheets. Users can go from a letter-size job to a CD-size booklet within minutes with minimal tooling required.

Coatings and Enhancements

MBO FC23/30 Web Coater

For the 23” and 30” digital web market, the MBO FC23/30 Web Coater is a complete unit and can apply Aqueous or UV coatings in high gloss, gloss, satin, matte and soft touch. It adds value and protection to direct mail and advertising materials, and can work with any finishing line and any press brand, including offset and flexo web presses.

Scodix PolySense 550

Scodix recently announced the release of PolySense 550, a new low migration food compliant polymer for digital enhancement. Compatible with the entire Scodix Ultra portfolio, the polymer augments existing Scodix applications with the ability to apply it to food-grade packaging. Applicable substrates include offset, HP Indigo ElectroInk and Lamination.

In the “good news for value-added print” category, in January Scodix announced that consumers ordered a record-breaking 50 million cards with personalized and embossed foils during the Q4 2020 Thanksgiving to Christmas holiday season in North America.

Cutting, Splicing and Sheeting

POLAR Transomat TRE Unloader

The POLAR Transomat is an Unloader that goes after the cutting system and re-creates the pallet—but with cut product—stacking the completed reams on pallets with perfectly aligned edges. The machine automates the palletization of the cut stacks, creating precise loads to transport to the next process. Additional automated units (joggers, lifts, etc.) can be added in stages to meet specific needs, or all units can be combined into one highly-efficient cutting system.

Bograma BSR 620 Servo Rotary Diecutter

Bograma upgraded the width of the BSR model to accommodate the B2+ sheet size in the new half sheet inkjet market. The BSR 620 Rotary Diecutter can take a 23.5” x 29.5” sheet, and is designed to support the commercial print and packaging market. The male-female die cylinder design gives the machine flexibility to tackle both single sheets and folded products, folding cartons, direct mail, labels, blister pack inserts, commercial work, business cards and much more.

Tecnau Zero Speed Splicer Roll 40 The Tecnau Zero Speed Splicer Roll 40 automatically changes input and output rolls, eliminating printer stoppages and paper waste for roll changes, and keeping your high-speed continuous digital color press running at full speed and full productivity. The machine permits mixing of paper quality, paper grade and web width between rolls—all at floor level, and with an upgrade path from the standard Tecnau single unwinder and rewinder. Produce mini-rolls for urgent work or switch back and forth between rolls job-by-job to form rolls with common destinations for finishing.

Duplo HC-550i Hydraulic Cutter The programmable DocuCutter HC-550i Hydraulic Cutter comes with operational and safety features not found in similar cutters of this size including a rail back gauge system, UL certification and a 10” touchscreen control panel. It effortlessly cuts through large stacks of paper up to 21.6” wide and finishes postcards, direct mail and perfect bound books up to 3.5” in height. It also comes barcode-ready to instantly retrieve any pre-programmed job.

MSE Sheeter for Low Volume Users

MAXSON Automatic Machinery Company of Rhode Island launched their MSE Sheeter as a solution for low volume printers and converters who want to sheet their own small batches of paper, rather than buying sheeted stock by the ream. The machine has a compact 6’ x 10’ footprint, and can sheet rolls up to 56 inches in width into segments from 13”– 52” in length, and in batches as small as 2,000 sheets per order.

And, finally . . . Taping

B&R Moll Digi-Taper System with Touchscreen

Take your taping projects offline with the B&R Moll Touchscreen Digi-Taper System. The 110V non-marking continuous feeder can support up to two tape heads, with products as small as 3 inches and as large as 20 inches in either dimension. The machine is simple to set up and operate with a digital touch screen display, catch tray, counter and the ability to manage multiple events. The small footprint makes it easy to move around and store when not in use.

Coming up in May/June

Want more print finishing technology? If you liked this article, you’ll love the webinar! Please join me on May 21 for the Finishing Technology Outlook Webinar—we’ll talk about these and other finishing innovations that are coming out this year. Also keep an eye out for my upcoming June article focused on the latest in finishing for the pharmaceutical industry.