Packaging Prototyping Goes Virtual

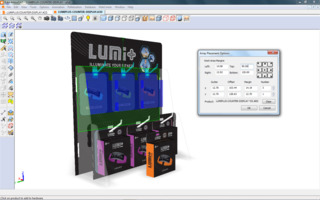

Picture if you will: a brand has designed a spiffy new eye-catching package design, which can be viewed realistically onscreen in three dimensions.

Picture if you will: a brand has designed a spiffy new eye-catching package design, which can be viewed realistically onscreen in three dimensions. Not only will it precisely resemble what the physical package will look like, but the 3D graphic itself can be used as an element on the brand’s website for branding consistency. Oh, and the virtual prototype itself has drastically reduced the costs of generating a physical prototype as well as sped up time to market.

Welcome to the growing world of virtual package prototyping.

“It in the past, prototyping has been very time-consuming and expensive,” said Larry Moore, VP of Partner Programs for Esko. “With some of the virtual tools, it’s much more streamlined and we can take a lot of costs out of the process by eliminating some of the iterations of hard prototyping.”

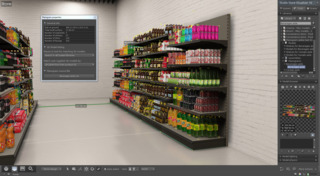

Prototyping itself is done for a number of purposes, some obvious, some less so. A package prototype is basically a three-dimensional proof that shows what the package will look like, as well as how graphics line up along the various surfaces, to ensure that important copy or logos are displayed properly. Prototypes are also used in mock-retail environments to allow designers, converters, and brandowners to see how a particular package design stands out in a shelf when surrounded by competitive products. A brand will also generate ultrarealistic prototypes long before the product even hits the market, and use those prototypes to create product shots and other collateral materials prior to the launch of the product.

The responsibility for producing a prototype varies from brand to brand. “We have some customers that have a package design group of their own and they will make their own prototypes for internal purposes and that they can share with vendors,” said Moore. “In 75% of cases it’s the converter.”

Prototyping has been accelerating these days, driven in part by the vast improvement in virtual prototyping. Must-have features in virtual prototyping solutions are of course the ability to integrate with various graphics files formats, but also the ability to simulate more realistic effects, such as lighting, substrate textures, and gloss or metallic materials. “If you take the typical launch of a brand, there might be five iterations of prototyping before the design ever goes to production,” said Moore. “They can make four of those in virtual form and then only send the final iteration to a printer and cutting/sample table before they go into production as a final safety check.”

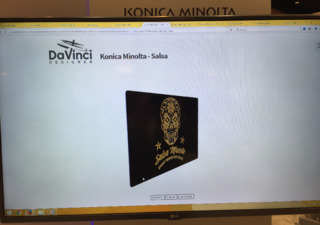

One of the biggest trends in packaging today is adding what are known as “digital embellishments” to packages, effects created by technologies popularized by MGI and Scodix. So while you can add, say, digital foil stamping to a package (or any other substrate, be it packaging-related or not), or a texture, or some other kind of 3D effect, how can you proof it, much less virtually?

At last April’s Collaboration in Packaging Production (CPP) Expo, Konica Minolta was demonstrating a program developed by OpenSoft (a subsidiary of Farheap Solutions) called DaVinci Designer, cloud-based software that lets designers add textures and other effects and create web-based 3D simulations that show clients—in a highly realistic manner—what that printed piece will look like. It can be rotated to show the client how changes in lighting or angle affect the appearance of the graphic, and how pronounced the 3D effect is.

Virtual packaging prototyping is even going further than just packaging proofing; it has the potential to have a measurable impact on the logistics of shipping that package. This involves tools that can integrate realistic representations of the product itself with the prototype. “We can take a 3D model of the product into our CAD application and build the package around the actual product,” said Moore. “That makes it very easy to create packaging that more accurately and more securely protects the contents. We can then take all of that digital collateral into the logistics world where we can lay out shipping containers, cartons, pallets, warehousing, and everything else.”

A case in point: one Esko customer makes a variety of home and garden tools, in particular, a small home rototiller. They took a 3D model of the rototiller, imported it into a CAD program, and designed the package around the rototiller. Then, they unfolded the virtual prototype and measured the dimensions. They realized if they made one small adjustment to the handle of the rototiller, they could shrink the package by two inches in one direction and an inch and a half in the other. “In doing that, it made the product more secure inside the package,” said Moore, “and it allowed them to increase the number of products that they were able to put in a sea crate from China [where they were manufactured] so it had an impact on the shipping costs and carbon footprint of crating and moving these products—all because they were able to interact virtually with the product, the prototype, and the structural design.”

Another aspect of prototyping can also be done virtually. Remember how prototypes are placed in mock retail spaces to see how they look on a shelf? That can now be done virtually as well. In fact, virtual prototypes are also starting to be used more and more for focus groups, as brands try to glean hard data on what packages the public prefers. This saves a small fortune on physical prototyping costs.

Still, as with anything new, there is some resistance to virtual prototyping, and many brands and converters, still prefer to do things the old handmade way. But that’s changing.

“The technology is there, it’s quite reliable, and people should look to take better advantage of it,” said Moore. “Everything is about reducing costs and the more efficient a company can become by reducing time to market as well as all the shipping and other issues, the better off our entire industry is.”