Who Is Buying Offset Presses?

The offset press buyer: Who are they and what are they looking for in a new offset press?

Customers, report press vendors, come from a broad mix: packaging and label printers; point-of-purchase printers; pharmaceutical printers; commercial printers, direct mail printers; book printers; Web2Print printers; and plastic and specialty substrate printers.

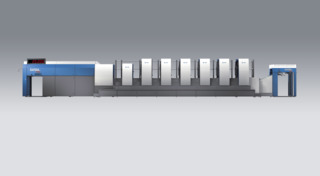

“The offset buyer today is looking to purchase a piece of capital equipment that will put more sellable sheets on the floor every day, makeready twice as fast as their existing sheetfed press and provide greater flexibility in coating applications to their customer base,” said Walter Chmura, vice president of technical sales, KBA North America Inc. “They are seeking efficiency in their workflow and seeking to move into new markets. “

Dee Paper Box in Chester, PA is currently installing a new Rapida 145 57-inch press—its first KBA. “Our new KBA Rapida brings us lots of opportunities,” said Steve Harrell, general manager of Dee Paper Box. “It gives us better graphics, improved color consistency, faster speed, and better control of the process. It provides us with more configurations. It will also help us enter new markets that we couldn’t serve before. This specially-configured press with unique automation and double coaters provides us with new capabilities and advantages.”

Last fall, Imagine! Express Minneapolis installed a new KBA Rapida 105 41-inch press with fully automated quality control and vision inspection systems. “Imagine! Express Minneapolis has added complete commercial printing and direct mail capabilities to its already lineup of equipment and services. The new KBA Rapida 105 41-inch press complements the company’s robust offerings in large and grand format UV printing, framing, and interior décor solutions. The upgrades, additions and enhancements will create a single facility with some of the most extensive capabilities available anywhere, said Bob Lothenbach, Imagine!'s president and founder.

Also last fall, Sonderen Packaging in Spokane, Washington added a new KBA Rapida 145 press. “Our advantage over our competitors has always been our flexibility, our quick turnarounds on short- and long-run jobs on short notice, and our dedication to serving our clients. The new KBA press allows us to keep this advantage and expand our portfolio,” said Matt Sonderen, a principal and director of quality management at Sonderen Packaging.

Sonderen’s new KBA press is equipped with the latest technology including the KBA SIS Sensoric sidelay-free infeed, the CleanTronic UV system with a pivoting washing beam for washing of blankets and impression cylinders sequenced with plate changing, and additional parallel makeready processes that contribute to significantly higher net production output. Sonderen’s press is also equipped with the KBA QualiTronic ColorControl inline color measurement and control camera system that monitors and maintains color consistency by taking a snapshot of every printed sheet.

Komori Continues Placements

Komori, too, is finding a range of customer types is buying its presses. Media Graphix in Atlanta installed a new five-color Lithrone G40 with coater (GL540C), the fourth Komori press the company has purchased in its 21-year history. The press is helping open up new doors for the company, to provide the high-end applications marketing agencies and product marketers require, said Media Graphix vice president Sam Asadi.

Media Graphix chose the Komori GL540C for its ability to efficiently print on a variety of substrates and produce outstanding print quality. Additional key drivers in the selection of the press were Komori’s KHS-AI intelligent software with self-learning and the PDC-SX color scanner that allows the press operators to get up to color and registration extremely fast.

Media Graphix reports it is running 16,000 impressions an hour on the GL540C and has cut its makeready time in more than half.

Data-Mail Inc., a full-service direct mail production company in Central Connecticut, installed its six-color Lithrone G40 with H-UV (GL640) to meet clients’ growing requirements for higher quality color, shorter runs and more value-added coatings, reported T.J. Smith, director of print services for Data-Mail Inc.

The GL640 also helps Data-Mail meets clients’growing demand for photo-quality print on a variety of substrates. The press’ automation and environmental efficiencies have resulted in Data-Mail increasing its production by 60 percent, decreasing makeready time by 30 percent, and reducing waste by 50 percent.

Zoo Printing recently added its eleventh Komori Lithrone 40-inch (LS40) press to support the significant growth the company is experiencing. Servicing the trade since 2001, Zoo Printing began its business with a Komori press and has grown through the last decade into a nationwide operation with multiple Komori presses in each of its three production facilities located in California, Kentucky, and New Jersey.

Zoo Printing plans to purchase another ten Komori presses in the next five years as it eyes expansions in new regions.

Growing with Goss

Goss’ offset customers include leading packaging printers and newspaper publishers looking to cost-effectively add commercial print options to its repertoire.

The first to install a Goss Sunday Vpak web offset system, Precision Press in North Mankato, MN is an innovative packaging and label producer for the food, beverage, and consumer markets.

The press is configured for flexible packaging applications, with Sunday Vpak 500 web offset printing units as well as a Goss in-line flexo and coating unit. The press is also equipped for UV and EB curing

Key features include quick-change sleeve adapter technology for efficient, cost-effective size changes, and advanced offset inking, tension and control systems –all key factors during the decision making process. Options for integrating flexo, gravure and digital stations into a Vpak press configuration to form a hybrid production line lets this technology deliver flexibility without compromise.

Goss also installed its Magnum Compact press at Advance Publications in Staten Island, New York. The six full-color Magnum Compact print towers and one folder add versatile, short-run capability in combination with output capacity approaching that of Advance’s existing double-width press. The new Magnum Compact system supports Advance Publications in accommodating a growing volume of contract newspaper, commercial and insert printing, and also back up a double-width press used to print the daily Staten Island Advance newspaper.

Goss Autoplate technology was a significant factor in favor of the Magnum Compact press, according to John Giustiniani, director of production at the Staten Island Advance, who said fast makereadies for successive jobs are a key to the success of his company’s business model. The fully automatic Goss plate changing system enables operators to change all plates or any combination of plates.

RYOBI MHI Graphic Technology

Graphco, which imports the RYOBI MHI line of new offset printing presses, noted its new highest profile customers at GRAPH EXPO 14. The custom-configured RYOBI MHI printing presses include 16 print units, two perfecting presses, and three RYOBI MHI/Panasonic LED-UV curing stations in total.

Now in its 115th year of operation, Woolverton Printing Company headquartered in Cedar Falls, Iowa with an additional location in Spencer, purchased an 8-up, RYOBI MHI 925P LED-UV perfecting press, Woolverton CEO and president John Lynch is looking to leverage the additional capacity to profitably keep pace with customer demand. The use of LED-UV technology to produce 16-page signatures that are instantly cured on all substrates, adds to Woolverton’s speed-to-market strategy.

In Lenexa, KS, J & J Printing, a TANGENT Corporation, will soon offer targeted packaging jobs with its 6-up, RYOBI 754 XLG Packaging Edition press featuring LED-UV instant curing. In operation since 1985, J & J Printing will continue its tradition of staying ahead of the technology curve with Kansas City’s first LED-UV press.

Messenger Press’ new RYOBI MHI 755XLGP perfecting press with aqueous coater is expected to provide significant increases in productivity and enhanced print quality, a necessity as this offset and digital printer expands its presence throughout Ohio and the Midwest. Headquartered in Carthagena, OH, the printer has been operating for more than 100 years.

Moving Along with Mitsubishi Presses

Trade and commercial offset printers are investing in Mitsubishi presses from RM Machinery Inc.

Up2speed Printing, a Hialeah, FL-based print shop that specializes in commercial and trade printing, added a six-color Mitsubishi 3000R convertible perfecting press, to facilitate growth.

Key considerations for Up2Speed include the 3000R’s ability to print two-over-four jobs in perfecting mode and six colors in straight printing mode. The company is looking to compete for larger, higher-quality jobs, now possible due to the sheet size, fast makeready speed, and high quality image reproduction delivered by the 3000R.

Founded in 1915 as Johnson Printing Company, Johnson Litho offers full-color printing with aqueous and ultraviolet coating. The company purchased a six-color Mitsubishi 3000S sheetfed press to help the Midwestern commercial printer compete in today’s print market.

The 28x40-inch press with tower coater and delivery extension will join the press lineup at Johnson Litho’s manufacturing plant in Eau Claire, WI, alongside a heatset web and a range of sheetfed presses.

The Diamond 3000S features high-performance preset systems, sophisticated remote-controlled adjustments and closed-loop color control. SimulChanger, Mitsubishi’s advanced, automated plate changing system, accurately changes all six printing plates on the press in a little more than one minute.

The ability to increase the level of service we can give while simultaneously reducing the cost of production will afford clients greater opportunities for achieving their communication objectives, reported Lance Papke, president, Johnson Litho.

Trade printer Best Deal Graphics & Printing in Scarborough, Ontario, expanded its stable of 40-inch Mitsubishi presses, investing in a Mitsubishi 3000TP perfecting press. The eight-color dedicated perfector offers automated features, closed-loop color control, and inline coating capabilities. Dual anilox coaters enable printing and coating on both sides of the sheet in one pass.

Purchased from RM Machinery, the 3000TP joins an existing eight-color 3000R convertible perfector with dual coaters and three 3000 series straight presses (two six-colors and one five-color), also equipped with coaters. The company has also ordered a 10-color 3000TP.

Marketing Card Technology, LLC (MCT), a Darien, IL-based firm that specializes in direct mail, personalization, and fulfillment services, installed a Mitsubishi 3000LX sheetfed press with UV-curing capabilities and complete plastics-printing package. The six-color, 40-inch Mitsubishi press is a perfect fit for MCT’s core business component, plastic cards. The company services the gift card, credit, healthcare, incentive, and prepaid card markets. The Mitsubishi 3000LX prints on paper, board, and synthetic substrates, ranging from two up to 40 points in thickness. A package of special press options added to the press prevents marking, warping, and static when printing on plastics and synthetic paper.