The Rise of Hybrid and Bespoke

Digital technologies in print and finishing are in a continuing race against market shifts and vice versa. Both hybrid and bespoke print solutions will play an increasing role, and we are in for some interesting times.

Where it Started

Analog press and finishing equipment provided us with the "one solution fits all" design, where production is primarily confined to disconnected processing steps, except for some flexo applications. It has served the printing industry well and continues to, however as the market demands change, there is a need to think about print production differently.

If you build it they will come.

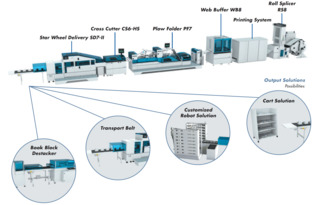

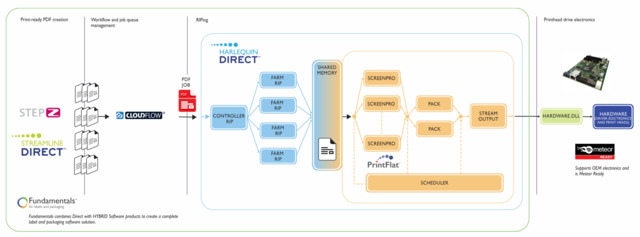

More timely and cost effective production was introduced with the advent of digital printing and finishing equipment and connected production processes. This digital technology fostered the on-demand market for printed products like marketing materials, labels, some flexible packaging applications and book of one applications as seen below.

© Hunkeler

© Hunkeler

These types of systems have been around since the introduction of electrophotographic presses in the 1990s. We have seen the development of many inline modular solutions that go from white paper (either cut sheet or roll) to finished product, including embellishment. These connected hybrid solutions have streamlined print production and enabled a whole new generation of digital printers to enter the industry.

If you can think it you or they can build it.

The introduction of inkjet took it further by enabling the imaging engine to decouple from the "standard" transport, and in its place become part of a custom or bespoke transport and solution. As a result, we are just beginning to see the creative opportunities that can be achieved.

A great example of a bespoke application is the V-Shape Alphaflex. This solution was developed to address the specific need of creating "one-hand-opening" single-serve packets of almost any liquid or powder from foods to drugs. It starts with rolls of blank substrate manufactured from recyclable homopolymers and other biodegradable materials that are suitable for composting. From there it is printed, converted, filled and sealed. It can print and fill manufacturing solution to create up to 300 filled single sachets per minute.

© V-Shapes

© V-Shapes

If you have an idea or a need for a bespoke print solution, there are companies that have significant expertise in engineering and manufacturing them as well.

Kirk-Rudy, located in Woodstock, Ga., has been engineering and manufacturing bespoke solutions for print and packaging material handling since 1967. It all started with a mail addressing machine, but now customer prospects come to them with a problem or an idea, and they build it. Much of what they have designed and built over the years focuses on material handling and transport. With the introduction of color inkjet technology, they realized that they could now use that know-how to develop bespoke print solutions as well. They use inkjet imaging technology from HP, Memjet and others with the printhead selection based on the end-use application. They also offer "ready-made" but configurable product design, like FireJet 4C, their recently introduced solution for envelope printing.

Engineered Printing Solutions located in East Dorset, Vt. is another bespoke print solution engineering and manufacturing company. With the moto "No Two Print Machines are Alike," they epitomize the term "bespoke print solutions." They make high-speed production inkjet printers that can print on almost anything. They specialize in direct-to-shape printers, and have produced solutions for some interesting shapes. EPS has built printers to print on bottles, bottle caps, saw blades and candy containers in up to seven colors. They can employ pretreatment to address the object's surface characteristics and robotics when necessary to transport, rotate or manipulate the object for printing. Picture the hat below being rotated and printed on all four sides.

Making it All Possible

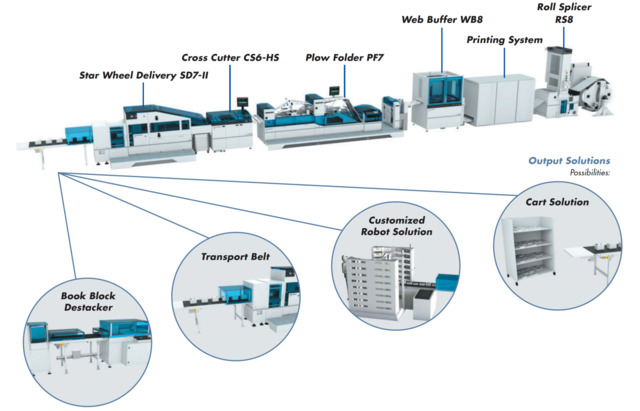

While inkjet heads have been around for a while, the development continues. However, the real driver for the explosion of bespoke printing solutions is the release of modular solution from the printhead manufacturers that help streamline the development time and costs to build a bespoke print solution. You can’t just take an inkjet printhead and attach it to a frame. These modular kits usually include printheads, advanced control electronics, and could also include other functional support tools including software. Kodak, one of the earlier entrants into the market, has been offering their Prosper S head modules for years, and recently added Ultrastream.

Over the years, others have jumped in as well. HP has been offering both aqueous and solvent-based printhead kits that can be used for coding and marking. Memjet has been offering complete kits since their initial VersaPass, and since added DuraLink and DuraFlex to address a broad range of applications.

To further widen the availability of different printheads for specific applications, Meteor and their sister companies from the Global Graphics group, have developed "Direct" a solution that pulls all of their expertise together to streamline the development of bespoke print solutions, which can include workflow and editing software all the way through to driving the printhead of your choice.

Exciting Times Ahead

As digital technologies continue to advance and market requirements continue to shift, there will be continued growth in hybrid print solutions and most likely an explosion in bespoke development. I can’t wait to see what ingenuity exists out there.