Packaging that Works

A new report by Smithers Pira, The Future of Packaging in North America to 2017, projects the packaging industry, currently value at $169.1 billion, to jump to $186 billion by 2017.

A new report by Smithers Pira, The Future of Packaging in North America to 2017, projects the packaging industry, currently value at $169.1 billion, to jump to $186 billion by 2017.

Used in a wide range of industries, from food and beverage to healthcare, cosmetics, and other consumer goods, as well for industrial sectors, packaging continues to demonstrate strength in the graphic arts sector.

Packaging and converting firms are able to touch down in a variety of industries, producing anything from corrugated cartons to labels to custom prototypes. The products are as varied as the companies they serve.

Thoro Packaging

Thoro Packaging in Corona, CA, doesn’t just make cartons. It makes fabulous folding cartons, says Jan Steiner, president and CEO of the 46-year-old company.

Independent sources agree: Thoro Packaging won the prestigious Judge’s Award for its 2012 Christmas Promotional at the 2013 North American Paperboard Packaging Competition.

Thoro does three promotional cartons a years; it’s biggest one is its annual Christmas promotion. The packager partners with one of its artist clients; Thoro creates the structure based on the artist’s concept. Envisioned with an art deco feel, the Santa Claus box demonstrates how a folding carton can be transformed into something beyond a traditional rectangular carton. The box is not only unique and beautiful, but also functional. Designed to hold candy, the front panel is perforated to become a movable bin and reinforced by a locking panel. The panels on the bin side form movable reinforcing flaps that prevent the candy from interfering with the movement of the bins. An insert helps separate the “nice” mints from the “naughty” chocolates.

“”Our promotions are a way for us to share something new with our customers, that they weren’t aware of before,” says Steiner. “Maybe it could be the substrate that we are using, or how we incorporate foil stamping into the structure.”

For its handbag promotion, Thoro foil stamped its name in the front, creating a unique look that is also a tool to fight counterfeiting.

Thoro Packaging manufactures 7,000 orders annually, running the gamut from prototypes for an initial look at the concept to production orders that range from 300 to 1 million. Its client base, while mostly centered on the medical pharmaceutical and cosmetic industries, also include companies from the fancy food, health and beauty, and electronics and software industries.

“All our customers value a good folding carton that will get their product to market safely and have a great shelf presence,” says Steiner.

The overarching trend right now is the customer’s concern for sustainability, says Steiner. ‘Our customers want to show that they are responsible citizens,” she notes.

Spire Printing and Packaging

Spire Printing & Packaging, headquartered in New York, produces work that often extends beyond folding cartons to leather binders and other custom work for a variety of clients, from restaurateurs to airlines to a film studio’s guide to its latest blockbuster.

One recent job, for an aircraft manufacturer, required a presentation and travel kit to house sales materials and specifier guides for sales pitches to prospective aircraft purchasers. The kit needed to house about 50 pounds of swatch books, paint chips, carpet swatches, metal finish chips, seat belt webbing choices, and more.

“We worked with our client to consolidate and organize their samples into a custom roller suitcase, sized for domestic carry on,” explained Bruce Weiser, owner of Spire Printing & Packaging. The suitcase is custom branded with embroidery and leather patches, and made from industrial grade cordura nylon.

The suitcase is “an ergonomic dream, the contents are organized and clearly labeled in custom binders made from super heavy duty upholstery grade synthetic leather, folders, and custom pouches,” said Weiser. “We trimmed and die cut the various samples into a uniform format for aesthetics, efficiency, and ergonomics, and made the aluminum inner frame with the strength and design so that the suitcase can be used as a seat during transit.”

For another client, Spire Printing & Packaging needed to create an attractive package to house the contents of a style guide for a blockbuster movie, complete with a secure DVD sleeve.

The packager created a binder with special finishing techniques, four-color process printing, a spot gloss UV coating, and matte black ring metals. The content of the book contained full color offset printed text and tabs, with a shrink-wrapped rush update. “To add security to the DVD sleeve we designed and produced a custom page with a protective flap,” said Weiser.

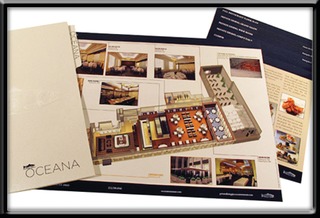

For a restaurant customer, a media kit was needed to market a flagship restaurant in a clear and concise way, highlighting the unique space, the diversity of its cuisine, and its unmatched quality. Spire Printing & Packaging created a banquet brochure housed in a file tab folder with a unique finish and a 3D embossed logo. “We assisted in every step of the project from handling the design, layout, and photography, to the rendering of a 3D floor plan to visually represent the restaurant at a glance,” said Weiser.

Joy Cone Company with Accord Carton

Accord Carton produced a more traditional packaging product for Joy Cone Company.

The medium-sized independent folding carton converter, located in Alsip, IL, specializes in high-volume packaging, as well as pharmaceuticals, consumer, food & beverage packaging. It’s reputation for manufacturing high-level products was sealed with a 2012 gold award for its 6ix Pack Carrier, custom carriers for custom beers, earned at the 69th Annual North American Paperboard Packaging Competition.

The project for Joy Cone Company, an independent, partly family-owned business, was for a new product launch. Joy Cone stresses its family ties, attention to detail, and old-fashioned quality in its cones—“it’s what makes our cones a joy to eat,” said Jennifer Chipka, assistant brand manager for the 95-year-old firm.

“The enJOY-a-Bowl is our first new product launch since the 2012 introduction of our gluten-free line of cake cups and sugar cones,” said Chipka. “ EnJOY-a-Bowls are a mini version of our best-selling waffle bowl.”

The Joy Cone Company wants to convey “a feel of endless possibilities with our enJOY-a-Bowls,” said Chipka “We highlight several different uses for the product in images on the packaging. We were also targeting a cleaner fresher look compared to our older packaging.”

The process began, not unusually, with a photo shoot. Rich Rock Media spent two full days photographing the bowls. Elisco Advertising then completed the artwork, directed by the retail sales group. The top requirement was a fresh, clean, and innovative look.

A true collaborative effort, Elisco came back with three ideal designs, and Joy Cone employees were asked to provide their thoughts and feelings for each design. All the comments were reviewed and helped in the selection of the chosen packaging. Once the artwork was received and approved by Joy Cone, the files were then sent to Accord Carton for printing.

The final product was printed in five colors with coating on offset, and didn’t require any special printing or finishing techniques. Joy Cone’s enJOY-a Bowls will hit shelves in the middle of March at select retailers across the US.

Walle Corporation’s High-End Flexo

For one of its clients, Walle Corporation, a leading label supplier to the consumer packaged goods industry headquartered in Alpharetta, GA, worked with one of its clients, a natural foods company, to help launch a line of dairy-free beverages.

The customer wanted to maximize the shelf impact of the product with an eye-catching shrink sleeve label that utilized a design highlighting the product’s unique contents. The artwork provided depicted smooth, creamy coconut with milk pouring out of a halved coconut. The graphics consisted of several areas of highlights and shadows composed of dots printing less than three percent, made all the more challenging by the film’s white background.

While the customer knew that gravure could achieve the desired printed results, it wanted to use the less expensive alternative of flexography, while not sacrificing the original design or shelf life impact.

The end result was made possible because of Walle’s investment in Esko HD Flexo technology, combined with the company’s 10-color flexographic printing capabilities.