Making Print Pop

Special press enhancements bring life and visual interest to the printed page.

Print is a powerful medium. Even the younger generations have responded in multiple surveys that they find the tactile nature of print appealing, and studies have been done that found most people tend to retain more information when they get it from print than they do from any digital device.

On the flip side, print is in direct competition with those digital mediums for the time and attention of every consumer in the market. Whether it’s a direct marketing postcard, a banner in a store window, or a promotional item being handed out on the street, print only has seconds to capture the attention of consumers away from their digital devices. And one way many printers are helping their clients’ print stand out is by using special press enhancements.

“We see embellishments as the driving force in differentiating print service provider’s (PSP’s) and converters offerings, no matter which market sector they serve,” said Amit Shvartz, VP of marketing, Scodix. “CMYK and the basic finishing abilities are becoming a commodity, but by offering customers embellishment, converters and PSPs can present their creativity, capabilities, add-value, and make higher margins on existing products.”

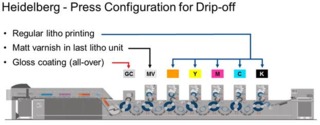

“Popular additions to print today are commonly used to add visual effect, feel, smell, and — from the printer’s point — adding value to the printed piece,” agreed Clarence Penge, vice president, Sheetfed, Heidelberg Americas. “That being said, drip off coatings that have varying levels of gloss and texture are most common today.”

Special enhancements run the gamut from coatings, to foils, to embossing. And in each of those categories the range of technologies and applications can vary widely, from machines that perform the enhancements offline after the rest of the work is done, to those that run inline with the press, applying the effects at nearly every stage of the process.

“There is a clear trend to custom build machine configurations to eliminate multiple passes and maximize profit while improving time to market,” said Penge. “Today, it’s common to have a 40-inch sheetfed press with multiple coating units. You’ll see the coating units in the front of the press (e.g Speedmaster XL 106-LYY-8+LYYL) where the first coating is applied immediately after the feeder and after the printing unit. Increasingly common in the middle of the press [maybe before perfecting( XL 106-5+LYY-P+5+L)] allowing printing and coating on both sides of the sheet in a single pass. In packaging you’ll see printing units, coating units and printing on top of coating in the last unit (XL 106-7+LYY-1). The main reason is simple. One pass special effect with improved quality, reduce waste by eliminating passes and the fastest time to market at a better margin.”

But inline or offline, the type of enhancements can vary greatly. “The type of embellishment a PSP might choose to provide depends on the market, work and brand requirement,” said Shvartz. “In fact, we do see foil as a popular choice among many converters and PSPs, but many other embellishments are gaining momentum as well. This increases not only the impact but the perceived value of a printed item, so it’s easy to see why PSPs often choose to add this capability.”

Technology Doesn’t Matter

It would be easy to dismiss special press enhancements as being for offset printers only, but the fact is, these effects are just as popular with digital printers.

“When it comes to the popularity of enhancements, we don’t see a great difference between those who use offset and those who use digital,” noted Roy Porat, CEO of Scodix. “The companies that are looking to add value to their printed products do so regardless of which production method they choose to work with. Each enhancement is impactful and easy to apply, and although we provide our services using a digital process, we see our products as being complimentary to most printing processes – be that digital, or offset.”

The trick isn’t so much with print technology the shop is using, but making a decision on which enhancements to offer based on what the shop can get the most value from. “Anyone can do commodity printing; doing it cost effectively while making a profit is another story,” stressed Penge. “Adding value to the printed product through special effects improves the sell price, and hopefully achieves the goal of the printed piece. My advice regardless of segment is to work with your vendors, as you will need to use their knowledge to help you become the master of these techniques.”

Penge went on to note, “Digital has finally been making inroads over the last few years with special effect raised coatings, just as sheetfed has done for decades now. Why or what path is better would ultimately be decided by manufacturing cost.”

“The challenge is when the run is a short or medium length. In those cases, usually the special effect will not be cost effective unless the PSP is using a digital enhancement press,” agreed Mark Nixon, VP of sales and general manager, North America, Scodix. “The value of being able to enhance a print, even if it is a short/medium run, using real foil, embossing or spot varnishing in varying densities, has a huge impact on the end user.”

No Limits

Designers have been creating amazing, eye-catching pieces for the entire history of print. And while enhancements have been around for almost as long, it’s only been in the more recent years as technologies have all gotten more cost effective that these enhancements have started to become more budget-friendly for the average print buyer. Combined with the need to make print stand out from not just other printed pieces, but from digital mediums as well, and it’s not hard to see why these enhancements are becoming increasingly popular.

Because the technologies have made it easier to apply enhancements to some or all of a piece, the only limits to what can be created, today, is the imagination of the designer and the printer. “In general, any enhancement or special coating added to a normal CMYK print will have an impact on the final product and provide an advantage over regular prints,” said Nixon. “However, it’s largely down to the designer to create something impactful as each enhancement application is unique. We’re continually amazed by what end users produce with our technology! With enhancements like embossing, spot UV, foils etc. and the opportunity to make print tactile as well as aesthetic, there is really no limit to the creative options available.”

And the best way to get those print buyers and designers thinking about what they could do with press enhancements is to let them see and touch examples. Nixon suggested printing a sample of one of their own jobs with and without enhancements so they can see for themselves how their own pieces can be transformed, rather than just show them samples that they may or may not be able to imagine in use with their own creative concepts. Once a printer has demonstrated how any piece can be more valuable with new textures, coatings or foils, then additional samples can be used to help buyers get a better idea of how much is truly possible. It becomes another way for the printer to be a partner, with valuable suggestions to help increase response rates and sales dollars, rather than just a commodity printer who delivers great print, but that’s all they do.

And that is the true value of special press enhancements. It allows a printer to offer their clients pieces that are far more likely to grab and hold the attention of consumers, which translates to higher response rates, higher brand engagement, and ultimately higher profits across the board. And it all starts with making print pop.