Automation is Key

Pre- and post-COVID trends drive changes in wide-format print software.

Prior to the "Year of COVID," one of the biggest industry trends in wide format and elsewhere had been automation, be it the physical automation of wide-format production using robotic arms and other mechanical means to move materials around, or the moving of files from intake through prepress, to production, and even to finishing—all untouched by human hands. A lot of this drive to automation had been due to difficulties in finding qualified staff to manually handle all of these processes. Color management is also not immune from the automation trend, especially as it requires more skill and knowledge than a lot of other prepress and production functions. And even in the realm of the experienced printer, color management—after all these years—remains a gray area.

“As we’ve seen over the last several years, the types of people that are working with print shops and working with RIP software has changed and evolved,” said Jonathan Rogers, international marketing manager for Onyx Graphics. “The reality is that color management and color matching are difficult, and require training. There’s a lot of this now new normal where owners are becoming operators, new people coming into the market are younger and they don’t have the time or maybe even the patience to do six months of color management research in order to fine-tune something.”

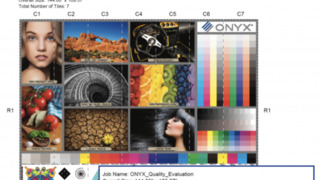

Late last year, Onyx released version 21 of its flagship ONYX suite of prepress solutions. ONYX 21 includes Swatch Books 2.0, allowing users to print, scan, iterate and report on an ideal color match, with options to add print mode-defined colors in a single click.

“With [Swatch Books 2.0], we’ve tried to make it as simple, frontward-facing and as interactive as possible,” Rogers said, “the idea being, how do we make it easier to match color? The main thing is to let ONYX do the work for you and take the guesswork out.”

Swatch Books 2.0, part of the new ONYX 21, aims to automate color management as much as possible.

Swatch Books 2.0, part of the new ONYX 21, aims to automate color management as much as possible.

That problem has only been exacerbated by the pandemic, with staff being discouraged or prevented from coming into the plant full-time (or at all). Having machines do as much of the work as possible minimizes the number of employees that need to be on-site at any given moment.

Another interesting feature in ONYX 21 is a way of not automating, but guiding the final graphic installation process via Tile Maps, an interactive PDF file used to guide installation crews (or even store employees) on how to install, say, a retail display, which can be like unboxing a jigsaw puzzle without a cover image for guidance.

“The install crew don't print the job, if they don’t necessarily know where all those tiles go,” Rogers said. “So they go to the business and they’re rolling stuff out on the ground trying to figure it out. Well, now we have the ability to just say, look, here’s the map, here’s the tile, here’s a list of where those tiles go.”

This probably wasn’t a concern when Tile Maps was on the drawing board, but it also potentially minimizes the time an install team needs to be in a particular retail or other public location, helping avoid COVID exposure.

Tile Maps are kind of an instruction manual for installing what can be complicated graphic displays,

Tile Maps are kind of an instruction manual for installing what can be complicated graphic displays,

Software has also been helping companies take advantage of the new applications that came out of the pandemic—safety and distancing signage, PPE and so forth.

Rochester Software Associates (RSA) offers software applications predominantly for the in-plant market, and the forces that affected in-plants mirror those that impacted everyone else. In-plants had a bit of a leg up over general commercial shops because wide-format printing has been a big application area for in-plants for a while now.

“We’ve been doing a lot more with customers who created a separate shop just for the sign business, which is its own entity,” said Vincent Tutino, director of product management for RSA.

RSA’s ImpactVDP, version two of which was released late last year, offers variable-data-printing templates for online ordering of print products, and also a variety of templates for wide-format graphics and signage. During COVID, it offered template help for “parking signs and other things that people needed,” Tutino said, “as well as signage for parks and recreation.”

RSA’s QDirect is a job and output management system that streamlines the acquisition of jobs in the print shop and routing to the best printer available. It integrates with ImpactVDP.

RSA’s QDirect is a job and output management system that streamlines the acquisition of jobs in the print shop and routing to the best printer available. It integrates with ImpactVDP.

“[In-plants] are printing tons of COVID material,” added Anthony Leccese, product manager for RSA, “as a lot of the rest of their business has dried up.”

One of RSA’s customers, Ithaca College’s in-plant in upstate New York, for example, acquired a flatbed printer before the pandemic and, like many other print businesses, started making masks and other PPE. RSA’s WebCRD is web-to-print software specifically tailored to in-plant printing departments. The new materials could then be loaded directly into WebCRD and an online storefront.

RSA’s WebCRD is a web-to-print software solution specifically tailored to in-plant printing departments.

RSA’s WebCRD is a web-to-print software solution specifically tailored to in-plant printing departments.

As for the trends that had been in motion pre-pandemic, count automation and a heightened emphasis on data security among the big ones. Cloud migration, which may not have been a major priority beforehand, suddenly became necessary in what quickly became a work-from-home world. RSA’s in-plant clients include very large enterprise clients, so “because of our history, we’ve been at the forefront of security in the solutions that we provide,” said Elisha Kasinskas, marketing director for RSA. “People want to move to the cloud” and need to feel secure about security.

The pandemic has also pointed out the importance of an online storefront, as consumers throughout the economy became more comfortable with e-commerce, and e-commerce became a greater and greater percentage of overall retail sales. Print buying is not appreciably different, and many print businesses have set up B2B and/or B2C sites, some specifically for COVID products. Throughout last year, I wrote about several print businesses that were using solutions, such as EFI’s MarketDirect StoreFront, to quickly set up COVID stores. (See “Benson Creates W2P Store for COVID Signage and Safety Materials” in our September 2020 issue.)

Benson Integrated Marketing created their B2C COVID estore using EFI’s MarketDirect StoreFront.

Benson Integrated Marketing created their B2C COVID estore using EFI’s MarketDirect StoreFront.

What will 2021 bring in terms of software? Well, I think we’ve had enough seismic changes for a while, so hopefully this year will be more of the same, at least in terms of software development. More automation, more attempts to make color management as easy as possible, and more taking people out of the prepress and production processes and making the workflow streamlined and easy for people who aren’t prepress experts. It will also hopefully help shops become flexible; all sorts of new applications are going to be emerging, so shops need to be able to turn on a dime and produce new stuff as the market demands it—and sell it through an e-store.