Décor’s Brave New World

Digital printing has designs on interior-décor applications.

When you think interior décor, fabrics might be one of the first things that come to mind. After all, fabrics and textiles certainly are utilized for an array of décor items – from furniture and wall coverings and pillows to carpet and much more.

But décor, don’t forget, also can include basically anything that adds to an interior’s aesthetic – from the aforementioned textiles to glass, ceramic tiles, flooring, fine-art prints, and, of course, signage.

And, we’re talking commercial as well as residential décor applications. Many print shops have explored selling into both segments of the décor market, with some very successful results.

An expanding market

Ken VanHorn, vice president marketing and operations, Mimaki USA, acknowledges the growing opportunities for digitally produced interior décor.

“Environmental graphics for office lobbies, medical (doctor, dentist, therapist, etc.) treatment areas, hotel rooms, etc., are desirable because of their softer feel that imparts a feeling of hominess,” says VanHorn. “Wall coverings, wallpaper, flooring and mats, curtains, upholstery, wall art, and bed coverings – these are all items that can be produced digitally.”

Depending upon the type of product, several different printing technologies can be used to produce interior décor output, including dye-sublimation, UV, eco-solvent, reactive, and pigment.

“For example, dye-sublimation printers and inks are being used to create customized polyester-based products, such as pillows, curtains, rugs, and window coverings like blinds and shades,” says Lily Hunter, product manager, Textiles and Consumables - Roland DGA. “UV and eco-solvent printing technologies are also being used to produce some of the same type of customized interior décor items, as well as wallcoverings (using environmentally-friendly media like Roland’s WallFlair removable fabric) and fine-art reproduction on canvas.”

Sublimation inkjet printing is widely used in digital textile printing, as most fabrics are polyester or at least polyester-mixed. There is more polyester sublimation run in using digital printing than in conventional printing, notes Patrick Clark, Next Wave Media Solutions co-founder and product and market development specialist. Next Wave is EFI Reggiani’s textile integration partner.

In the days before digital, polyester and dye-sublimation represented as little as 10% of the total pie of décor, with pigment representing 50%, Clark notes: “As more and more as digital emerges and the practicality of sublimation printing becomes more popular than there will be more polyester used in the future of decorated textiles.”

However, pigment printing is an emerging technology, especially since it can be used on almost all types of textiles substrates, including cotton.

“Being able to print on cottons will be very important to the future expansion to digital textile market for décor,” says Clark.

Moving efforts in-house

Personalization/customization is one of the biggest ongoing trends impacting the interior décor/textile markets, says Hunter: “There is increasing demand for items like customized pillows, wallcoverings, lampshades, and rugs that are decorated with attractive graphic designs,” she says.

With the ability to customize and print on a variety of media, digitally produced interior décor continues to branch out. “We’ve had customers who’ve digitally printed fabric for sling chairs and other furniture, in addition to more pillows and curtains,” says Angel Georgious, senior marketing specialist, Imaging Supplies, Canon Solutions America. “The digital textile market is still growing at exponential rates, especially since there still aren’t a lot of people doing it.”

The increasing selection of fabrics and media choices opens the door to new and emerging markets that are receptive to this technology, resulting in more opportunities for business. “Rather than outsourcing, many deliverables requiring soft/fabric media can now be produced in-house with familiar printing equipment and RIP software,” notes VanHorn.

Innovations near and far

At two of last year’s big tradeshow events – drupa and Graph Expo – EFI touted “The Imaging of Things,” a takeoff, of course, on the “Internet of Things,” but also a clear indicator of its approach moving forward. The company sees opportunities – for itself and its customers – as focused on delivering greater customization and appeal in a wide variety of segments, including décor.

The Artistri PK2600 inks developed by DuPont for cotton textile roll-to-roll printing on EFI Reggiani printers were announced at drupa last year. The new inks are designed to offer color and hand comparable to reactive printing, excellent fastness performance, and high-level digital printing performance, without steaming or washing production steps that add turnaround times, the company reports.

Another of EFI’s recent innovations is its AquaEndure inkjet technology, a water-based inkjet platform developed for applications in areas like wall coverings, wraps, and flexible signage. According to EFI, AquaEndure inks cure using much less heat, have no odor, and can adhere to virtually any substrate.

Its décor printing technology comes by way of EFI Reggiani, which offers a range of printers for interior décor. The ReNOIR line of printers are able to process any kind of substrate using a beltless digital printing system, says Clark. When run with the new AQUA reactive inks, printing results are improved while ink head life is extended.

Roland is constantly innovating to develop inks that are fast-drying, extremely durable, and offer wide-color gamut. These include its Texart dye-sublimation, ECO-UV, and Eco-Sol MAX and Eco-Sol MAX 2 formulations. Its eco-solvent inks are GREENGUARD Gold certified, so they can be paired with “green” media’ like Roland’s WallFlair removable fabric to produce interior décor that’s ideal for settings such as healthcare facilities, schools, and daycare centers. Additionally, Roland’s new TrueVIS series inkjets feature improved integrated printing and cutting capabilities as well as specially formulated, cost-effective TrueVIS Inks that make them unbeatable for creating wall decals and other types of interior décor, explains Hunter.

Roland’s dye-sublimation offerings for the interior design/textile segment include the Texart RT-640 and Texart XT-640 dye-sublimation printers; Texart SBL3 dye-sublimation inks, and Texart sublimation transfer paper. Roland also provides the Roland VersaUV LEJ-640FT UV flatbed printer, the Roland VersaUV LEJ-640 hybrid UV printer, Roland ECO-UV inks, Eco-Sol MAX and Eco-Sol MAX 2 Inks, and Eco-Solvent wide-format printers and printers/cutters.

Mimaki’s offerings include the TS500P-3200 printer, a 129.9-inch (3.2 meter) wide, dedicated transfer model developed for production transfer runs to create extra-wide textile applications such as soft signage, home furnishing, and hospitality fabrics.

Its 77-inch wide, roll-to-roll TS300P-1800 printer dedicated transfer paper model, engineered for the dye sublimation industry, has an available inkset that provides fluorescent yellow and fluorescent pink inks that “make colors pop,” VanHorn says. Both models are manufactured to print onto extremely thin transfer paper, and include a high gap printhead that is unaffected by cockling – a common occurrence when using thin media.

Mimaki’s TX300P-1800 direct-to-fabric textile printer was designed specifically for direct-to-textile applications and is suitable for users creating samples or short-run pieces. It includes new print heads with a high gap setting that enables printing on thick or thin textiles, plus woven patterns or raised fiber surfaces, while maintaining accurate ink droplet placement.

Generating buzz in Canon’s corner is its new UVgel printing technology and new line of roll-to-roll printers, reported to be a game-changer across the wide-format arena, including interior décor. UVgel UV –curable ink UV instantly gels on contact with the media, promising precise dot placement and area control for consistent high-quality images at high speed.

The UVgel technology also consists of new hardware developments, including “next generation” piezoelectric print-heads, and an LED UV system that doesn’t’ require any heat to set the ink onto the fabric.

“Heat limits what you can print on,” remarks Georgious. “If you apply heat, you are going to impact vinyl. Our new technology will have no heat involved, so we won’t have those issues. “

Through its partnership with Media One Digital Imaging Solutions, Canon also offers the d.gen Teleios Series of wide format dye-sublimation inkjet printers for full-color graphics direct-to-fabric printing. The printed fabric is then passed through an inline fixation, unit causing the dye to sublimate into a gas that infuses the image deep into the polyester fibers. According to Canon, this provides a final result that is permanent, durable and with vibrant color and detail.

The short-run solution

As with other segments of the graphic arts, moving from conventional to digital allows the print provider and its customers to produce custom and/or short runs, and a service that’s attractive enough for the customer to pay a premium, says Clark.

There is also time saved on design cycles. With the conventional process, it might take 6-8 weeks to come up with a design, plus production time. With digital, you’re able to create designs on demand, giving the designer freedom to take creative risks.

It also gives the retailer selling the interior décor the option of not holding inventory, and only produce what is selling or needed.

“In the décor market, flooring – such as carpets and mats –are typically bought in large quantities from Asia,” says Clark. “The retailer buys 50 different designs of kitchen mats, puts them in retail outlets, such as Bed, Bath and Beyond, but inevitably, one design will sell better than another. Between 30 to 40% of the cost to the consumer is in close-outs and inventory-carrying costs.”

If you are producing these products on demand, however, those costs are eliminated.

How Digital Printing is Serving the Décor Marketplace

The market is... Digital printing...

• Moving from mass production to mass communication • Enables custom production in small or large quantities

• Looking for new sustainable materials that will improve LEED score • Is producing quality output with less manpower, waste, and environmental impact

• Searching for innovative yet affordable design-rich products • Offers an endless range of design patterns to meet the need for small or large batch production

• Meeting customer needs for quick turn around • Reduces turnaround time and improves time to market to meet retailer needs

• Improving production efficiencies • Enables custom production in small or large quantities

• Moving from mass production to mass communication • Reduces waste and inventory; streamlines supply chain

Source: Keypoint Intelligence/InfoTrends “Profiting through Digital Printing in the Décor Marketplace” report (keypointintelligence.com)

Primary Color: Making the Cold Zone Cool

When MillerCoors needed to update their presence at Angel Stadium in Anaheim, they turned to Primary Color as their print service provider of choice. The objective: Freshen everything up with brand new graphics – static as well as digital – and create the Coors Light Cold Zone as a “must-do” experience at the stadium. As a company well-versed in environmental branding and décor (both interior and exterior), Primary Color was a natural choice for this project.

“MillerCoors had been updating all of its locations across the country, and wanted the space to be a unique, flagship experience – particularly since they recently opened an Irvine office and would be entertaining clients and visitors at Anaheim Stadium,” says Primary Color’s Cameron McMackin.

Primary Color had just one month to plan, fabricate, and install. The shop’s project managers worked onsite at the stadium every day for the entire month-long process, and were in touch daily with the project’s engineers and fabricators as well as their outside contractors.

Primary Color produced a variety of applications in the overall installation, including (but not limited to):

- A soffit buildout and the creation of a party deck;

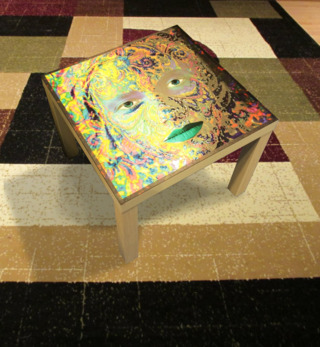

- Branded tables, chairs, and umbrellas;

- Backlit bar signage, made out of aluminum mounted to 0.1875-inch milk acrylic with LED lighting behind it; the graphics were on 3M brushed aluminum adhesive vinyl.

- A 48-foot baseball “timeline” wall mural UV print ( x 56-inches high), printed onto 3M 180-10 adhesive vinyl.

- Foam signs, can signs, and blade signs;

- A spectacular Coors mountain graphic for the elevator housing; and

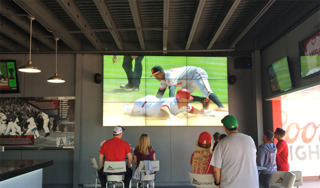

- A nine-screen video wall featuring nine 55-inch LCD flat screens.

Other work included new interior lighting, sconces, the wiring of LED signs, refinishing the elevator shaft, creation and installation of awnings, painting of the space, and more.

As you might guess, Primary Color utilized an array of equipment, materials, and supplies for the work. For the record, its wide-format printer roster includes an EFI Vutek TX3250r dye-sub printer, two Vutek GS5500LXr Pro UV LED printers, a Vutek GS5000r UV printer, two Vutek HS100 Pro UV printers, a Seiko ColorPainter M-64s printer, two Epson Stylus Pro 11880s and two Stylus Pro 9890s.

“Managing the implementation of so many different elements at the same time was a tremendous challenge,” says McMackin, “especially with the deadline of one month to plan, fabricate, and install.”

The result, however, was well worth the work: Coors now has a complete “must-do” Silver Bullet Experience built into the Angel Stadium location for the entire baseball and event season. You can take a 3D tour of the space here: primarycolor.com/coors-light-cold-zone-3d-scanning.

A global visual-solutions company headquartered in Costa Mesa, California, Primary Color (primarycolor.com) has been turning heads and getting results with next-level output and marketing like the Coors Light Cold Zone since 1984. In addition to its offices in El Segundo, Primary Color also has offices in Costa Mesa, Irvine, and Hollywood, and Shanghai, China.

Primary Color dedicates more than 70,000 square feet on its production floor to wide-format production alone. Beyond its wide-format production, Primary Color offers an array of print capabilities, including litho print (standard and oversized), narrow-format digital and high-speed digital/silkscreen. Additional services range from structural design/fabrication and prototyping to pre-media and design, fulfillment, and distribution. The company is FSC- and 3M-certified company, and is also certified as a G7 Master Printer – all of its devices are color-managed using the G7 method, ensuring color-matched campaign materials across all print media and substrates.