Water, Water… Anywhere?

With all the attention that new ink technologies have been garnering, it’s easy to overlook one of the oldest categories: aqueous.

With all the attention that new ink technologies like UV have been garnering, it’s easy to overlook one of the oldest categories of wide-format printer: aqueous. Aqueous inks—which are based on a dye or pigment dissolved in water (with some other chemicals thrown in)—have been around since the dawn of wide-format printing, but were largely supplanted by first solvent inks and as of late by newer ink technologies.

We need to be careful with what we mean by terms like “aqueous” and “solvent.” Chemically speaking, water is a solvent; if you recall your high school chemistry, a solvent is anything that dissolves something else (which is called the solute). Water will quite readily dissolve substances like sugar, salt, instant coffee, and, of course, dyes and pigments (think of watercolor paints). In terms of performance, however, water-based inks are not ideal for many applications and substrates. What we call “solvent” inks feature dyes or pigments dissolved in a solvent that is more aggressive than water, specifically, various kinds of volatile organic compounds (VOCs). These inks can be noxious to work with, and require ventilation and special handling, certainly compared to water-based inks. Eco-solvent inks strike a balance and use chemicals that are more aggressive than water but less aggressive and less noxious than hardcore solvents.

Other ink technologies like latex and dye-sublimation are also technically aqueous inks, as they consist of colorants dispersed in a water-based vehicle, although they do not fall into the traditional “aqueous” printer category. But, hey, there’s no tradition like a new tradition, so we’ll be looking at latex—arguably the future of aqueous—later in this article. Dye-sublimation is a different kettle of fish entirely, and is beyond the scope of this story.

The challenge with inkjet inks—or any ink—is that you have to get rid of the liquid vehicle, the solvent in which the dye or pigment is conveyed to the substrate. True solvent inks do this by a combination of evaporation (the word “volatile” means “easily evaporated at normal temperatures,” although we could argue at some length about what “normal” temperatures might be) and absorption into the substrate. UV inks dry via polymerization under exposure to UV radiation. Aqueous inks also rely on the evaporation/absorption combo but—and if you have ever dried your hands using those electric hand dryers in public rest rooms, you know the problem—it takes time and heat. So when you’re trying to increase printing speeds, using water-based inks is a challenge, as anyone involved in production inkjet can tell you. Also, water-based inks also run into the problem of requiring special substrates and/or coatings, which can make an individual print more expensive.

Down By the Water

That all said, aqueous inks and printers do have a place in the market. “If you’re looking at traditional aqueous, some printers still use it, but for the most part it’s more a specialty or niche product today,” said Ken VanHorn, director of marketing and business development for Mimaki. “It’s still very much used in CAD and GIS, but other than that, the sign and graphics market is mainly solvent, latex, and UV.”

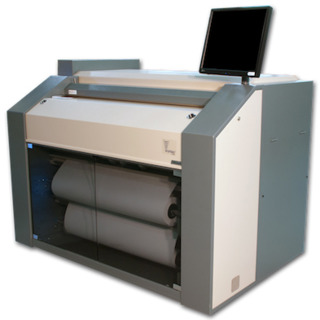

“Aqueous inks are used for line drawings, maps, and GIS applications,” said Oriol Gasch, Director Americas Large Format Printing for HP. “They are also used for photo applications.” HP’s DesignJet lineup is aqueous-based, as are the new PageWide printers—single-pass devices which include the recently launched PageWide XL 8000 40-inch printer—are also aqueous printers, and are targeted at the AEC (architecture, engineering, and construction) and technical printing markets. The advent of color capabilities to what had been strictly monochrome technical printing has had a number of advantages, allowing architectural plans, for example, to color-code individual elements or systems, like the electrical system vs. plumbing on a building plan.

Single-pass aqueous printers are also being used for retail-ready signage, “point-of-sale and point-of-purchase posters where a four-color system is good enough,” said Gasch. Think of supermarket posters promoting the week’s specials, for example. Sure, a lot of POP and retail signage does require more than CMYK to hit certain brand colors, but a substantial amount doesn’t necessarily require 100-percent color matching, especially if the speed and cost of printing are of greater importance.

Speaking of single-pass printers, Memjet-based devices use aqueous inks. Memjet printheads are used in a wide variety of configurations, but in the wide-format and signage spaces, RTI Digital’s Vortex 4200 has carved out a niche in the map, GIS, and AEC markets globally. “It has also proved to be ideal for point-of-sale signage such as supermarket and other retail promotions,” said Erik Norman, President of RTI Digital. “Its users are pursuing new applications using media not typically associated with dye-based aqueous ink such as backlit films and repositionable adhesive-backed vinyls with good success.”

Epson’s SureColor T Series printers are aqueous devices aimed at the technical printing markets, while Canon Solutions America’s Océ ColorWave 900 and the Xante Excelagraphix 4200 are Memjet-based printers aimed at not only technical printing applications, but also posters, POS, and other display graphics.

“Aqueous inks are still very prominent in the indoor signage market,” said Ray Bauer, Production Marketing Manager, Channel & Field Marketing, Ricoh Americas. “However, where Ricoh is seeing a lot of traction, beyond indoor signage, is with latex and UV curing printing. Signage overall is a hot industry right now. The move towards having the quality to produce vibrant outdoor signage that really tells a brand story is very strong.”

The Next Generation?

The past several years have seen latex inks penetrate, so to speak, into the market. To reiterate the definition, “latex” is a generic chemical term that refers to, says Wikipedia, a “stable dispersion (emulsion) of polymer microparticles in an aqueous medium.” We should all know by now that latex in this context is not related to the natural latex exuded by plants or the synthetic latex used to make gloves or other rubber-like items. As a result, latex inks are perfectly safe for those with latex allergies. Latex inks, then, are water-based (there are other mild co-solvents mixed with water, much like traditional aqueous inks).

“We see latex as the next generation or the next step up from aqueous,” said Bauer. “It allows printers to expand the type of media it can print on, including textiles, and gives printers the ability to add new components to their portfolio with new types of outdoor applications.”

“We’re in our fourth generation of latex ink and latex is now starting to become extremely viable in POP, vehicle wraps, and certainly wallpaper for interior décor,” said VanHorn.

Latex inks are capable of printing on a wide variety of coated and uncoated substrates—much wider than traditional aqueous—for both indoor and outdoor use on the same machine. Why is that?

Latex printers apply the ink to the substrate just like any other ink, and then apply heat to evaporate the water. But latex printers apply a separate process that cures the latex polymers creating a thin film on top of the substrate—in much the same way that UV curing creates a plastic film that sticks to the surface of the substrate. As a result, said Gasch, “you can have more variation in the substrate, and can print on self-adhesive vinyls for vehicle graphics, fleet graphics, wraps, and posters that get mounted on a board.” Latex printers can also print banners and soft signage on various types of fabrics.

The Look Ahead

Traditional aqueous printers often get short shrift today, and while they may not get as much attention as UV flatbeds, dye-sub rollfeds, or even latex, they still occupy an important niche in the market, as the technical printing applications for which they are well-suited are healthy ones, especially now that construction has rebounded from the housing crash in 2008. And while print service providers aren’t necessarily clamoring to get into the “blueprinting” market, offering technical printing services can be a successful complement to other types of wide-format and signage work—and an aqueous printer would be a far more cost-effective option than virtually any other ink technology.

Latex, meanwhile, can be a versatile alternative to, say, dye-sub. “You don’t have to have a post-printing transfer process,” said VanHorne. “Latex lends itself to doing more mainstream things. You’re not going to do a backlit sign with dye-sub.”

“Although the majority of volume being produced through our installed base is still within the GIS and AEC markets, we are seeing our customers pursuing more and more traditional graphics applications,” said RTI Digital’s Norman, “especially promotional store signage and wall art where fast turnaround times and a combination of low re-order quantities and increased versioning places pressure on other print methods.”

“We see the latex printing industry growing quite strongly,” said Ricoh’s Bauer. “As one of the more environmentally-friendly inks, making this switch is a clear focus for many of Ricoh’s customers. Added to that, latex is also more user friendly, is odorless, and doesn’t require ventilation.”

Until the day comes when a single ink can print on every conceivable surface and substrate—without being the most toxic substance on the planet—PSPs looking to expand their capabilities will need to think about what it is they want to print on and then choose the most appropriate ink technology. And that may very well be aqueous.