Getting Creative with White Ink

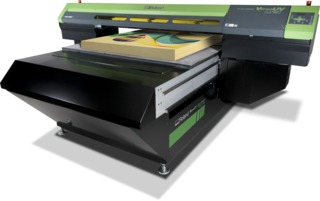

White ink provides the opportunity to expand digital print and inkjet offering to include dark and unusual substrates and special effects.

It’s not every day that a product comes along that is a game-changer for an industry, but that is exactly what white ink has been to the printing business. For the digital print and inkjet industries, white ink has provided the opportunity to expand their offering to include products printed on dark and unusual substrates and create special-effect pieces.

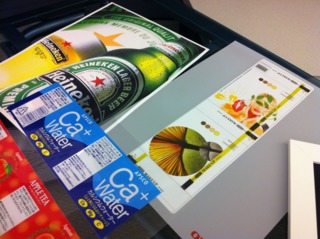

To achieve various effects, white ink technology can be used as an undercoat on colored and other substrates, as a spot color to brighten areas, as a post coat on clear substrates for backlit and other products, and as a pre or post coat to allow metallic substrates to show through for special effects.

Garments Go Dark

While white T-shirts and other white garments had long been a staple for the printing market, the advent of white ink allowed for the inclusion of darker garments, dramatically increasing the selection and service printers were able to offer their customers. While white ink makes a statement by itself on a darker garment, it is also used as a base for colors to make them pop.

“In textile printing, white ink support is a requirement when it comes to printing on dark garments. The CMYK inks used in digital textile printing are translucent, so in order to achieve the full-color gamut and saturation, you need either a white garment or a white base layer on dark garments,” explained Oliver Luedtke, marketing manager, EMEA, for Kornit Digital.

When working with white ink on garments, more coverage is needed, according to Deana Leelachat, marketing manager for Anajet. “You don’t want any pinholing, especially if you’re printing something that needs the white underbase. To prevent that, you have to make sure that every little fiber is covered. That is achieved by a combination of good pretreating and white ink settings.”

“White ink typically requires a flood over the substrate,” concurred David Hawkes, group product manager, Sign Products & Textile Printers for Roland DGA. “This will cost more than simply printing on white media.”

Leelachat agrees. “For direct-to-garment printers, CMYK has just one cartridge per color, while white has two or more to help with the speed of the printer,” Leelachat explained. “For example, our original printer had four white cartridges, and they weren’t printing, say 100 prints per cartridge; all four cartridges would run at the same time. In order to get a good vibrancy, you have to put more white ink per dot range when you print. And, because certain colors - such as the yellows - are going to need 100 percent white behind them with the color on top, you could use a lot of white ink to get their brightness and vibrancy. That drives the cost up.”

The garment also needs to be pretreated with a solution when using white ink, because without pretreatment, the white ink would sink into the shirt and the result would be dull. “The pretreatment creates a type of “flash” that the white ink is able to sit on top of, so you can get the vibrant whites,” said Leelachat.

Kornit’s NeoPigment printing process includes a water-based pigment ink combined with an in-line pretreatment. This process works with a variety of fabrics, such as cotton, polyester and blends, according to Luedtke.

He added that, since the white layer is usually the part that makes for the largest amount of ink on the garment, the characteristics of the white ink have significant influence on the look and feel of the garment. “With our NeoPigment Pure ink that we introduced a few weeks ago, we have made a significant step towards creating a hand feel that rivals all kinds of conventional production methods, particularly those used in fashion and apparel.”

Products Stand Out

With variable data printing, when printing on clear material or dark substrates, using white ink allows for printing beneath the colors, noted Mark Goodearl, senior manager, Ink and Post Sales for Inkjet Business, Inkjet Solutions for EFI.

For example, with regard to QR or bar codes, smart phones or reader applications would not be able to pick them up if they were against a clear or dark background. “Multiple layer printing can be used in that scenario beneath the color, not only to gain proper color on a substrate that doesn’t give you that reflectivity, but to have things stand out, like the codes,” Goodearl said.

But white goes way beyond the practical printing of bar codes. In fact, the ability to print white on dark substrates changes the product offering completely for printers. They can now print white on black or dark paper to create striking formal invitations, menus, marketing pieces and more.

But some white inks are too translucent to get a bright, solid white without several passes through the press, and then you can end up with registration problems, notes the blog Mohawk MakeReady. To solve this issue, HP developed ElectroInk White, a white ink developed specifically for digital sheet-fed presses. “They created it to print as true white on colored paper,” noted Mohawk MakeReady.

Rich Egert, vice president of Global New Business Development for OKI Data Americas, noted that his company has introduced the C941e, an enhanced, five-channel digital printer that has CMYK, plus white or clear toner in the fifth position.

“Clients and print shops use the C941e to make money. The device differentiates them from the other 10 print shops on the street if they are the only ones who can print white on colored paper, on-demand” Egert noted. “White on black or other dark colored media is eye popping. And the print shop can make more money because it is now offering something that no one else can do.”

Challenging Substrates

White ink is much more than just a new ink color, stressed Hawkes. “It opens up a variety of new applications,” he noted. “The ability to print with a base coat of white ink allows a multitude of new substrates to be used for variable data.”

“Because of the white toner, which can also be used as an undercoat, we can now print on things like metallic papers – the golds, the silvers, the bronzes, pearlescents and so on,” stated Egert. “Under a normal print process, if you can’t undercoat with white, you have a translucent and it shifts all of your imaging. So, we have the unique ability to either underprint or overprint, which expands your range of options.”

But, for some unusual substrates, such as a dark material or a metallic, “you need a very dense, very opaque white to provide total coverage and get color neutrality of the substrate,” reported Goodearl.

“All substrates have different printing properties,” stressed Hawkes. “The good news is that today’s technology let’s print service providers print on almost anything. The bad news is that there is a lot of testing and experimentation required. Adhesion, dry time and opacity all need to be determined before going into production.”

Special Effects

Experimentation and education are key for getting the most out of white ink, according to industry professionals. “The problem is primarily in the prepress arena, or in just understanding what can be done with white ink,” offered Goodearl.

“White isn’t always a flood, it isn’t always a spot; it can be done in percentages, so it’s not full coverage, it’s not full density,” he continues. “You can achieve a lot of different effects in subtle ways or in very prominent ways by using the white.”

For example, a mirrored, colored or metallic substrate can be chosen, and white can be used to mask out areas certain areas. “The result is that it looks like you have a metallic ink in your printer,” Goodearl stated.

“You also need to have the ability to control the density of the white ink so that you can achieve frosts or translucent effects,” he offered. “You can print on a clear material using 10, 15 or 20 percent white coverage and it turns it into a nice frost and gives it a translucent effect that you can use to achieve some interesting applications.”

“In some cases, when the white layer and the CMYK layer have been printed already, you can apply another layer of white on top of the printed image. This is called ‘highlight white,’ and it creates fascinating, shiny images with an impressive texture,” said Luedtke.

Goodearl added that white ink can be used in multiple layer printing to achieve a day/night backlit effect. The results is a single layer of color from a front-lit application, or double layers of color to give it the vibrancy it needs to have when it’s backlit.

White ink also allows for changes in the image from day to night. “There are examples where, when it’s daytime and something is front lit, you have one image. But when you turn out the lights and illuminate it from the back, that layer of white allows certain things to come through with the illumination from behind. You can actually have hidden messaging or hidden designs within a print,” Goodearl reported.

White ink is changing the landscape of digital and inkjet printing, and allowing for the fabrication of exciting, eye-popping and creative products.