The Sky is the Limit: The Future of Digital Color Production Presses

From direct mail to publishing, home décor and packaging, digital color production presses are transforming commercial print.

Color production printing is migrating to digital platforms. And this trend is expected to accelerate. In fact, researchers at Smithers Pira predict that digital printing will continue to grow in most print sectors across the world.

The firm’s report, “The Future of Digital vs. Offset Printing to 2022,” estimates that in 2017, digital print accounts for 16.4% of global print and printed packaging in value terms, and will reach 19.1% by 2022 as new high-performance equipment fuels the analog-to-digital transition at printers and packaging converters worldwide.

“Digital production presses can take many forms,” said Erik Holdo, vice president, graphic communications/industrial prints line of business for Konica Minolta. “Everything from higher-speed, full-color, toner-based devices, to inkjet products, and both cut-sheet and continuous-feed devices.”

He adds that, until recently, the digital inkjet market was focused on transactional, low-value prints—but the industry is changing.

“We have found a particular area of disruption around the high-quality, large-sheet marketplace,” he said. “The competition is heating up in that part of the market as aqueous inkjet providers are yielding better quality results.”

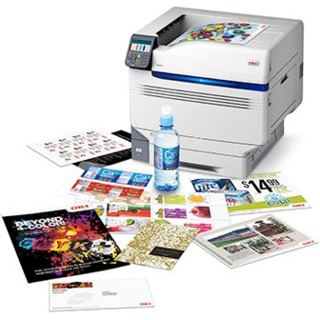

According to Jim Fuchs, product marketing specialist for Oki Data Americas’ C900 series production printers, “Digital is going to continue to take over print production because of the efficiencies that can be offered.”

Len Christopher, worldwide NexPress product manager for Kodak, says broader media compatibility is also driving the adoption of digital platforms. “Support for thicker substrates, for example, allows print providers to run plant tags and POP for smaller chain stores,” he said. “If you have 100 stores in a chain, the job does not lend itself to an offset litho process.”

John Fulena, vice president of commercial and industrial printing for Ricoh USA, Inc., notes that advances in digital wide-format platforms are further expanding media options. “We are able to print on things like glass today,” he said. “The workflows are almost identical to a commercial print workflow, and it doesn’t take a lot of money to get into these businesses.”

Xante’s president and CEO, Robert Ross, advises shops to leverage digital for deluxe items, such as wedding invitations, holiday cards, and graduation announcements. “There is a growing market for specialty prints,” he said. “These applications deliver an 80% margin on average, while bulk printing generates around 3%—and bulk printing is typically bid out to multiple shops.

Making it personal

Ross emphasizes that, while advances in digital hardware platforms continue to make headlines, print quality and the ability to personalize applications are largely driven by software today.

“The right digital workflow can generate great color that is vibrant, a unique print that pops, and a product that the provider can sell for a premium,” he said, adding that Xante’s iQueue workflow software includes hundreds of customizable templates for brides, grads, moms to be, grand openings, and more.

Eric Hawkinson, senior director, marketing, for Canon Solutions America’s production print solutions, points to advances in variable data software as a game changer in the world of custom prints. “Digital printing platforms can handle quantities of one to hundreds of thousands while incorporating endless versions of variable data into a single print run,” he said. “Digital presses are also significantly cheaper for fast-turnaround projects.”

Which is why, he explains, industries like publishing are also embracing the technology. “Digital presses allow book printers and publishers to print smaller runs, print specifically for on-demand orders, and resurrect out-of-print titles without the need for inventory storage.”

Filip Weymans, vice president of marketing for Xeikon, adds, “Personalized prints were a challenge years ago, but with online media now there is so much information available that the personalization of communications can be much more effective.”

Delivering high-end appeal

While software and hardware continue to work together to meet consumer print demands, digital processes have yet to completely unseat analog processes for higher-end embellished applications.

Holdo sees the tide turning, though, with print providers adding foils, spot UV coatings, textures, and other dimensional elements to digital prints. “Brand managers are concerned about color gamut and overall quality for applications such as light packaging,” he said. “Light packaging is one of our highest projected areas of growth as it is currently estimated to be over a $500 billion market in the value of prints—and only 2% of that is digital at this point.”

But creating premium prints today often requires more than superior imaging, says Fulena. “Finishing is going to be a huge trend. Print providers need to consider what they are doing with an application, such as whether it’s being folded, going onto a carton, or getting creased. Those are the kinds of things that make the difference between being profitable—and not.”

At the very high end of the market, digitally printed home décor elements such as textiles and wall graphics are also growing in popularity.

“Offices, hotels, and restaurants want to create an atmosphere that appeals to consumers,” said Weymans. “Today you can take any kind of vacation picture, drop it into a workflow system, and separate it into different panels. It happens automatically, starts printing, incorporates instructions on how to apply the wallpaper, varnishes it, and sends it to rewinding.”

Automation Equals Efficiency

This type of “lights-out” solution, Weymans predicts, is where the industry is headed. “In the workflow arena, you see that people are automating their processes a lot, striving for more efficiency and more lean manufacturing.”

Christopher agrees, emphasizing that digital presses can help shops both expedite production and dramatically lower their running costs. “The ability to migrate offset work to digital platforms gives them fast turnaround, fast proofing, and an easier approval cycle,” he said.

While automation is a key objective for many print providers, there are times when the ability to manually control the press is also critical.

“Anything that can only run at one speed has inherent limitations to it,” said Christopher. “You might slow the press down to run thick synthetics and speed it up for direct mail applications. So we have designed the press to make it easy to switch between various modes.”

Lou Stricklin, director of product marketing for Oki Data’s industrial printing group, emphasizes that, because the technology and workflows involved are still relatively new, many print providers struggle with just how to price their digital prints.

“It is important to show print providers and the design community how to profit on short-run digital applications,” he said, adding that cost calculators and other estimation tools can help.

Another common challenge is ensuring that digital prints appeal to today’s increasingly online and mobile consumer.

“Our buying habits are changing,” said Fulena. “Millennials don’t read newspapers; they read phones. The printed piece has to go hand-in-hand with a brand’s e-commerce presentation, and print providers have to be creative.”

Shaping the future: ink, toner, and media

That is where new, emerging ink, toner, and substrates come into play, says Hawkinson. “Inkjet advances continue to come in the form of media and ink. We work directly with paper mills and media vendors to rigorously test and qualify products, and even co-develop papers designed specifically for inkjet printing.”

Fuchs emphasizes the important role new white toners and inks play in expanding design options. “When added as an undercoat for CMYK prints, white enables printing on darker substrates, and the result is a much more finished look than plain white paper provides,” he said.

Holdo adds that conductive ink technology is also advancing, and promises to help brands better engage consumers and address growing security concerns.

“We are currently looking at new technologies in conductive ink printing and printed RFID chips,” he said. “It is possible to create a print that allows someone to press a button and have a light come on, for example, on a package or greeting card. Using a conductive ink, you can also test that a package is original, and you can even serialize that RFID to validate that it is a legitimate product and not a counterfeit.”

On the horizon, Holdo sees luminescent inks as another industry game changer. “It may be three to five years out before it is practical, but luminescent inks will be applied via traditional methods like inkjet, and light up when power is applied to them,” he said. “There could be applications for signage, point of sale, and food safety where printed sensors could monitor the condition of a product’s packaging throughout shipping.”

As for the future of digital presses, Ross says, “There is only so much growth in traditional print, so we are going to see a convergence with print shops broadening what they do.”

According to Holdo, “The sky is the limit. I expect to see innovations that exceed our imagination today at a pace that matches what the PC experienced just a few years ago.”

Weymans added, “It’s very important for those in the printing market to stay educated and informed on all the various options out there. They need to make sure they are making sound investments in the technology based on facts and figures.”