Inkjet Innovation Week Highlights

New Inkjet Hardware, Software and Media Driving the Market Forward

Covering the inkjet industry, we participate in a lot of industry events, often as speakers or reporting on new announcements, sometimes simply as attendees because we like to learn new things. All of the events that we had planned to support in 2020 have now been rescheduled (drupa) or transitioned to a virtual event (thINK, Inkjet Summit, Printing United). While we miss the opportunity to reconnect with customers and colleagues in person at these events, this may actually be a boon for many inkjet buyers.

Most print organizations are facing travel restrictions and budget constraints due to the COVID-19 pandemic. If you are looking to invest in inkjet presses or software, you still need to gather information. Recognizing this challenge, there are a host of suppliers stepping up to curate information for you. Virtual events are so prevalent now that it puts the entire future of live trade shows in question for the foreseeable future.

Since curating inkjet information for buyers is very DNA of Inkjet Insight, we stepped up with our own Inkjet Innovation week, June 15-19, where we organized the latest inkjet announcements in the context of current market trends and new application segments. Since we can’t do justice to five hours of in-depth webinars here, this article will cover:

An overview of trends in production inkjet in the document and packaging space

Snapshots of new inkjet product releases

Highlights of recent software updates driving inkjet productivity

Overview of new inkjet papers and specialty media opportunities

Recordings of all of the webinars as well as supporting articles and white papers are available at https://inkjetinsight.com/inkjet-innovation-week/

Production Inkjet Trends

In the market segments where inkjet is entrenched, like transaction printing and direct mail, new product releases have made inkjet accessible to smaller enterprises with lower volumes and CAPEX budgets. This involves controlling the purchase cost, running cost and footprint of the device while delivering a level of quality suitable to the market. We refer to these as entry-level inkjet and the latest of these entries are in the B3 sheet-fed market.

However, most of the R&D in inkjet right now is focused on expanding into graphic intensive markets in documents as well as several aspects of packaging. These markets require higher ink coverage, higher resolution and overall quality on a wider range of substrates. OEMs have responded by adapting print heads, ink chemistry, paper handling and drying technology to enable water to be eliminated from the process more quickly enabling higher coverage and wider media compatibility.

Drying is particularly important to enabling simultaneously higher coverage, quality and speed. One of the technologies we covered in depth was near infrared drying technology from Adphos Group. Adphos combines near-infrared light energy, management of the NIR energy, integrated hot air knives and moisture extraction to deliver exceptional drying results for production inkjet. Their combined approach slows ink migration into the substrate allowing pigment ink to bind to the paper surface more quickly than with just heat or air circulation alone while delivering a flatter finished product. You can find measured results of drying tests in our recent white paper “The Impact of Drying on Inkjet Performance” on InkjetInsight.com.

Another trend designed to support more discerning markets is the inclusion of integrated spectrophotometers and other automated quality control functions into these high-end presses. Let’s look at the latest announcements in production inkjet and packaging.

Web-fed

The two most recent releases in high-speed web-fed inkjet, excluding those dedicated to the packaging market, are from HP and Kodak.

HP has beefed up their inkjet production line up to compete with commercial offset work on coated and uncoated stocks. The HP PageWide Web Press T250 HD with BrilliantTM Ink runs at 500fpm with a 22” web width. Three print modes range from high, color-critical detail to less critical for ink savings and production output. HP is offering an upgrade path to the T250 HD with Brilliant Ink for all T200 family of presses. Offering:

HDNA dual drop weight print heads using a highlight drop size of 3 pL to enhance detail and tonal clarity

8x nozzle redundancy greatly increasing jet repeatability

HP Brilliant, high chroma ink chemistry delivering higher color fidelity and wide color gamut incorporating difficult to reach reds and blues

Upgraded HP Color Vision system - every image is measuring four color planes, delivering nearly 3x the inspection as the T240 HD with mono cameras

To make things easier for the customers running all types of stocks, HP has replaced the anilox flood coat primer station on the T250 to a jetted system. HP Optimizer now runs in-line with the rest of the printheads and has been enhanced with a new, fast-drying chemistry which jets drop per drop to ink placement, immediately binding the ink to the jetted optimizer.

HP is boasting a 30-50% higher gamut on coated than GRACol, providing a glossier ink look and feel. Testing has shown that the new ink chemistry helps difficult demand colors such as reds and blues. Which anyone in inkjet printing knows is not easy to replicate in cmyk.

The Kodak PROSPER ULTRA 520 is engineered to maximize productivity by printing across a broad range of substrates using the industry’s most versatile, highest quality and cost-effective water-based inks. As a complete system, the PROSPER ULTRA 520 is a game-changer that will help printers profitably grow their businesses across a range of applications, including direct mail, marketing collateral, catalogs, books and more. The PROSPER ULTRA 520 Press is scheduled to be available at the end of 2020.

Targeting commercial and publishing markets, Kodak has released the Prosper Ultra 520 based on their Ultrastream writing system which employs high-precision placement of smaller, perfectly round, satellite-free drops to enhance image quality. With resolution of 600 x 1800dpi and media compatibility ranging from 45 to 270 gsm, including high offset gloss, the press is positioned for a wide range of applications, including direct mail, marketing collateral, catalogs and books. It also offers high productivity with a 520 mm web width producing 2000 A4 pages per minute and an integrated intelligent print system for monitoring quality for multiple quality modes. The new press will reach the market at the end of 2020.

Sheet Fed

Not too many years ago, the Fujifilm J Press was the only production class sheet-fed device on the market. While the J Press remains the fastest B2 press on the market, sheet fed options have since grown dramatically spanning sheet sizes from B3 up to B1 and targeting a diverse range of markets as well. There have been two major releases in 2020, both in the B3 sheet space, with MCS targeting the entry-level transaction print market and Canon expanding their reach into graphic arts applications.

The MCS Merlin K146c is based on the Kyocera TaskAlfa 15000 C. It has Kyocera piezo heads, four color stations, a 4,800 sheet paper tray, a cart stacker and uses heated ceramic tile forced air for drying. With native resolution of 600dpi and support for up to 400gsm media, it is a fit for several markets, but MCS is focused on transaction printing, letter mail, work books and other “business color” documents. The device actually has the option to run at a higher resolution, but MCS would rather under-promise and over-deliver. With the goal of reaching new inkjet buyers and providing a compelling cost model, the purchase price for the Merlin K146c comes in at $200,000 USD or less, including training operators, and there is no click charge. MCS is marketing the machine with a shared support model that keeps costs down while providing buyers with the support they need to stay up and running.

By contrast, with the introduction of two new VarioPPRINT iX models, the iX3200 and iX2100, Canon is focusing on the needs of general commercial printers for high image quality on a wide media range and flexibility to run mixed media jobs at full speed.

The iX3200 produces 320 A4 ipm (images per minute) as compared to 210 ipm for the xi2100, which is about 8% faster than their respective iSeries models. The resolution has been increased to 1200 dpi as compared to iSeries+ at 600dpi, along with enhanced drying and registration control. The other big advancement is in the compatible media range, which covers 60 – 350gs(/40# text – 130# cover) uncoated and 90 – 350gsm(60# text – 130# cover) offset coated. This includes instant media switching with a printer input module supporting four trays of up to 4,500 sheets and the ability to connect multiple PIMs for max of 13,500 sheets in 12 trays. Although the iX Series may look much the same on the outside, with new heads, new inks, new dryers, a new sheet control and more, this is a new device for Canon that closes previous gaps for their target market.

Packaging and Labels

From flexible and direct print to pre-printed liner, packaging is moving to inkjet. New devices are paving the way for small runs and creative personalization in markets which require high runs of 10,000-20,000 units or more.

Inkjet technology has provided a cost-effective way to offer new market opportunities to big brands needing fast-paced changes in messaging and product graphics. Inkjet enables integrating custom runs of one along with mass customization into what has been a mass-produced market.

Miyakoshi launched the MJP30AXF, an aqueous inkjet, flexible packaging press, able to take short- and mid-range runs. However, the press is sized to fit the productivity needs of flexible packaging customers. The web width of 31 inches/790 mm supports a maximum print width of 30 inches/750 mm. By its nature as a continuous web-fed device, print length is limited only by the length of the roll itself. An inline corona pre-treatment and primer coating station enables compatibility with a wide array of transparent films and laminates such as PP, PET and Nylon, with thicknesses from 12 to 100 microns. High coverage and speeds of up to 164 feet/50 meters per minute are also supported through an updated hot air circulation drying system.

The device has a native resolution of 1200dpi using piezo print heads with dual drop sizes of 2 and 3.5 picoliters. CMYK plus double white ink provide vibrant color reproduction and excellent coverage/concealment. Because black, cyan, magenta and yellow inks are printed with tight registration and dried before a double layer of white ink is jetted, there are no white lines in pieces where windows are perforated. Other important quality features include automatic fine registration control and nozzle compensation to adjust for print head “jet-outs,” banding, gaps or other artifacts. Miyakoshi is currently taking orders for the new press.

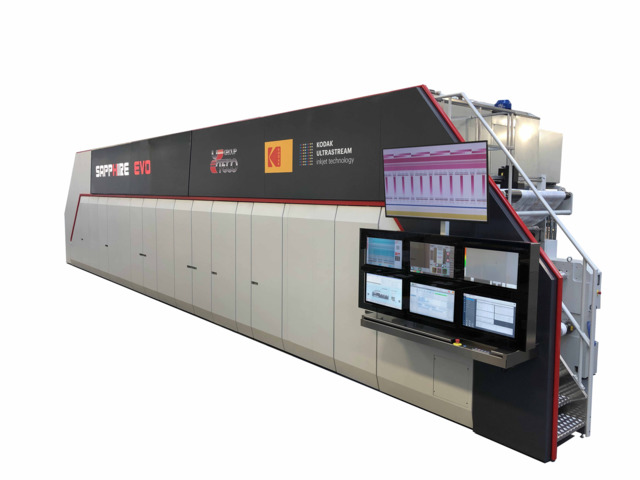

The Kodak Sapphire EVO Press was developed in partnership with Uteco. Designed as a high production digital inkjet press, the Sapphire EVO expands packaging print capabilities, with a cost-effective and highly flexible digital solution for high-speed, high-quality applications.

Utilizing KODAK Stream Inkjet Technology, this environmentally friendly, water-based pigment ink press offers excellent CMYK print quality on a variety of papers and plastic film materials such as PP, BOPP, PE and PET. The web press is equipped with KODAK Stream inkjet lineheads and driven by a Kodak high-speed digital front end. With a maximum web width of 650 mm and a print width of 622 mm, it achieves production speeds of over 150 meters per minute. This press also offers what Kodak calls their “Personal Care Pigment Inks,” which are certified for skin contact on personal care products and comply with regulatory requirements for indirect food contact in the EU and the U.S.

SCREEN has developed a new high-speed, water-based inkjet system specifically designed for the flexible packaging market. The PacJet FL830 is currently scheduled for release in Q1 2021.

This 1200dpi press can handle media up to 830 millimeters wide at speeds of up to 75 meters per minute. The CMYK and white water-based inks conform to relevant food safety regulations.

PacJet FL830 is able to meet a wide variety of print needs, ranging from promotional to production applications. It targets small lot jobs of less than 4,000 meters, an area that can be problematic for conventional analog production. At present, the system handles both PET and OPP media and SCREEN GA is working to further expand compatibility based on industry requirements.

The VaiJET 106 is a joint venture between Koenig & Bauer and Durst. When released, the press will print seven colors, CMYK plus gamut extending and brand colors printing at up to 6,000sph in 1,440 dpi. The press uses aqueous inks from Xerox to meet requirements of food-safe packaging applications. It can combine pre-coating and litho print units to produce the branded or variable elements of a job. It manages substrate movement using a suction belt to ensure an exactly defined clearance to the printing heads, printing board and rigid materials in offset quality. The print heads can be replaced by the operator and automatic cleaning of the printing heads with a technological solution compensates for loss of individual jets.

Xeikon and Flint group combined their technology and fluid innovations to develop a new post-print, single-pass printing press utilizing food-safe water based inks. Targeting corrugated packaging converters, this press offers printing on coated and uncoated corrugated sheets up to 1.6 meters wide by 2.8 meters long running up to 150 m/minute (492ft/min).

The packaging market is not just for stand-alone presses. Colordyne Technologies has developed an entry-level, digital print enhancement called the 3600 Series AP Retrofit. This solution offers lower equipment costs, wider width and higher print quality for use with analog presses, web handling or finishing equipment and production lines running under 150 feet (45 meters) per minute.

The 3600 Series AP Retrofit is a compact, single-pass inkjet engine that allows existing analog equipment to incorporate the benefits of full color digital printing while maintaining its original functionality. Benefits include faster turnaround times, on-demand production and affordable short-run printing. The 3600 Series AP – Retrofit, powered by Memjet’s DuraFlex technology, uses aqueous pigment inkjet for added print durability and is uniquely designed for quick, low-cost integration.

Canon announced significant enhancements to the LabelStream. Expanded UV color capability plus optional orange and white ink channels make it easier to match a wider range of brand colors, and achieve high white opacity without compromising on quality or reliability. The new white ink channel achieves up to 80% opacity at 36 m/min in a single pass.

Canon also introduced entry-level and hybrid configurations for the LabelStream 4000 Series to support more complex applications. A custom mix of UV flexo, embellishment and finishing units are compatible with the process, forming a fully-integrated, single-pass label conversion line. This mix of conventional and digital technologies enables a complete inline production of high-quality self-adhesive labels.

Software

Software also plays a key role in driving innovation in inkjet. While we can’t do justice to all of the updates and releases so far in 2020, there were several notable announcements covered during innovation week. The first two announcements, from Global Graphics and ColorGate, relate to the RIP that comes with your printer.

Global Graphics announced their Direct software that reads and writes directly to your press, without needing a harddrive. Direct is a fully integrated product portfolio featuring Harlequin RIP technology, Mako for file optimization, plus ScreenPro and PrintFlat for inkjet digital printing, providing tight integration with printhead drive electronics. Integration also encompasses software from Meteor Inkjet and workflow for labels and packaging from HYBRID Software. Direct reduces image processing times, while handling large print volumes and speeding up the time to print.

ColorGate is also addressing the RIP data challenge, but in a different way – through the render. They are now able to address color at the object level rather than examining each pixel. These enhancements have delivered a speed increase of over 400%. Version 2.0 has been updated to Adobe’s PDF Print Engine 5, supports spectral spot color definitions and brings compatibility with PantoneLIVE. Improved spot color support for PANTONE, Freie Farbe spot color libraries and additional settings for the Ink Saver feature provide the ability to automatically set color correction to a particular deltaE tolerance while protecting spot colors from adjustment.

Racami has updated the Alchem-e Dashboard and Alchem-e Flow with an updated UI and overall improvements in productization of the environment, enabling faster integrations and implementations. During Inkjet Innovation Week, Racami provided a sneak peek at coming enhancements including the use of Artificial Intelligence tools to streamline data mapping and customer onboarding, as well as complex job scheduling. Racami added their own billing, payment and resource transformation modules to the third party tools already supported.

Ultimate TechnoGraphics focuses on imposition and finishing automation. Advances coming soon to their Ultimate Impostrip solution can reduce labor, calculate jobs and save a lot of time for customers. The new release will support even more complex nesting algorithms while adding increased scalability to an already solid platform. More details on the importance of imposition and nesting across a range of application segments can be found in the “Future Proof Your Business” series of white papers on Inkjet Insight.

The latest version of Hybrid’s PDF prepress production tool designed for labels and packaging has undergone a metamorphosis with a new user interface and a range of new automation features supporting VDP and PDF workflows. With Stepz 6.0, HYBRID Software now also offers an entry-level version of PACKZ with a reduced feature set designed for quick implementation and ease of use in digital print environments.

Inkjet Paper Trends

Inkjet paper for aqueous inkjet needs to be particularly resilient. The cross-fusion function of paper is gradually destroyed by water if not extracted quickly. When heat is applied to extract from the ink, the paper can become dry and brittle showing visual curl and cockle and potentially interfere with finishing devices.

Since books require a high level of high speed finishing of multi-page signatures, books require conforming paper options with specific PPI (pages per inch) and typically low gsm. Thin papers, which are coated or highly calendared, are well suited for books because the fibers are more sealed or compressed, which slows the migration of ink into the paper. Keeping the ink from diving in too quickly and providing accurate dot fixation provides clean images and text clarity. Several papers have been released to target this demanding market. In addition, Inkjet innovation Week covered paper products that helped inkjet users save money and expand into new markets.

CVG released its new, eco-friendly 50gsm thin sheet. This high range PPI paper is not coated, but rather an inkjet treated offset grade which has gone through a heavy calendering process, compressing fibers and smoothing the paper surface. This paper does not require any primers, even at top production run speeds, and utilizes a high opacity (’XF pigment’) to deliver opacity of 92.5%. It has been shown to have good dimensional stability which supports optimal ink consumption, lower drying temperatures and clean finishing production.

CVG also released the third generation of its LetsGo papers. Tests performed on the HP T240 at 220 TAC in quality mode show color gamuts nearly matching Fogra39 and an average of 300,000 gamut colors between weight ranges offered. CVG is enhancing their manufacturing process to provide an even silkier inkjet paper with a coated look and feel and aspiring to expand the gamut even further.

Evergreen, the only coated mill in North America utilizing HP ColorPRO technology, has added an inkjet option to their TruSpec family. This new book grade offered in 45, 50 and 60# is qualified for aqueous pigment inkjet presses and fits directly into the specification range for books, magazines, textbook and catalog print markets with a high range of PPI requirements. It is SIMRA (previously NASTA) certified for textbooks. In head-to-head product comparisons with industry coated book grades, TruSpec has proven to provide up to 25% faster print speeds and superior lay-flat, even at higher ink loads

The Navigator Company of Portugal has released Navigator Premium Inkjet grade, a splice-free product. All rolls are guaranteed “no splice” which maximizes printed paper yield. Their paper grades are sold around the globe through distributors. Navigator utilizes Eucalyptus Globulus, commonly known as southern blue gum, a species of tall, evergreen tree which has a higher number of fibers per weight unit giving the paper lower porosity, better opacity and superior paper formation.

Another way that paper products can help printers save money and enter new markets is through paper conversion. InfoSeal is a paper converter that helps printers expand into new market segments without investing in additional finishing equipment. InfoSeal can process rolls or sheets of inkjet compatible papers into pre-finished specialty products ready for inkjet printing. This makes preparing self mailers easier to achieve and reduces overall manufacturing costs. Available products include pre-finished snap pak self mailers, remoist glue, business reply envelopes, poly windows, integrated cards and unique dynamic perforations that are cost efficient and production tested. These products, using InfoSeal’s conversion process, have been approved by all major inkjet OEMs for both rolls and sheets.

During Inkjet Innovation Week, we provided a deep dive into a wide array of hardware as well as supporting software, paper and converting services. Since we are writing this based on deadlines for a printed publication, we know that there are several new releases that will come out during the magazine production process. In addition, there were an array of web-fed and sheet-fed releases in 2019 that are available now. Look for updates on even more inkjet innovations at InkjetInsight.com.