Production Inkjet Update: Closing the Gap

The last year’s worth of new equipment sets the stage for the new tech to come

We’ve all been hearing about production inkjet devices for several years now, especially since drupa 2012. But is it just a passing fad? Will inkjet technology really be able to meet the challenges in commercial print? Does it have the staying power this industry needs?

Simply: yes.

According to InfoTrends Group Directors, Barb Pellow and Jim Hamilton in a recent Xerox Business Development Series webinar, “Inkjet: Closing the Gap,” by 2018, US production color inkjet page volume will exceed that of digital color toner. “High-speed, color inkjet is closing the gap between offset and digital print,” Pellow said. “What we’re seeing is high productivity and lower consumable cost that’s causing today’s run-length cross-over points to make digital printing very competitive with offset.”

But what makes inkjet so attractive. According to Pellow and Hamilton, it’s because inkjet offers all the advantages of digital printing—personalization, electronic collation, just-in-time manufacturing, workflow automation, high-speeds, and productivity—to higher volume applications. And we can see that’s been the case. Most of the growth can be found in high-volume markets such as books and manuals, direct mail, transaction documents (see page XX of this issue for more details on how inkjet is impacting this market), and even brochures and catalogs.

And vendors have responded with an influx of devices to enable print service providers (PSPs) to dive into these high volume applications. You can see highlights of production inkjet devices that have been introduced to the market in the past 12 months within the following pages—and stay tuned for more later this year as we move toward drupa 2016.

Tech Talks, Market Listens

But what technological developments are driving this market segment forward? Experts point to several factors.

“Paper, ink developments and advancements, and advances in color and ink management tools are some of the key factors that will drive the high-speed production inkjet market forward, especially with respect to enabling color applications traditionally associated with offset,” said Mike Herold, director, Continuous Feed Inkjet Technologies, Ricoh. “From Ricoh’s perspective, our technology innovations will continue to be developed around creating more value for our end-users and directly addressing their needs. We will drive technological innovation that includes flexibility, print quality, reliability, and ways for our customers to achieve their own business objectives. As we develop new technological advancements, we’ll make them available as field upgrades.”

“Without question,” commented Michael Poulin, senior manager, Production Print Solutions, Canon Solutions America, “the ability to print on offset stocks without the use of a bonding agent is game changing in the market place. The ability to print 1200 x 1200 DPI is also a distinguishing factor and allows book and magazine publishers the opportunity to use digital technology capable of the appropriate speed and quality.”

According to David Murphy, worldwide director of marketing and business development, IHPS division, HP, inkjet technology is advancing rapidly and users should expect to see greater innovation in quality, productivity, and versatility across all platforms. “As new developments in printheads, inks, media, software, firmware, electronics and transport systems are introduced, HP production inkjet customers should feel confident that their investments are protected against technology obsolescence,” said Murphy.

The ability to scale a product, also plays into its strengths. According to Dustin Graupman, vice president, Ink Jet Business, Xerox, scaling the technology to the higher end of the market will help expansion into traditional offset markets for applications such as catalogs, newsprint and general commercial print.

“Bringing inkjet down market will enable migration of preprinted offset shells, overprinted with cut sheet monochrome digital devices to full color digital printing at a more cost effective price point,” said Graupman. “Lower price points will make redundancy much more cost effective for our customers.”

Bumps in the Road?

But with any new technology, forward momentum does not always come at a steady or straight path. As vendors continue to develop new equipment, they are also endeavoring to overcome various challenges and obstacles along the way.

“Interestingly, these development challenges are closely linked to the issue above regarding rapid technology advancements and customer upgradability,” said Murphy. “In the last five years, the market has seen more than one inkjet press manufacturer introduce a new product series or technology that is not available as an upgrade to currently installed presses. This can be frustrating for a PSP who may have invested, say, $2 million in a press two years prior and then learn that its manufacturer has introduced a new technology enhancement that is only available on a different platform.”

HP, however, offers an upgrade path for its customers. For example, a customer who purchased a T300 Inkjet Web Press six years ago, could upgrade that press to a faster T350, and again to a more versatile and productive T360—all without removing the original press from the production floor. “That upgradability path provides tremendous peace of mind to the customer,” said Murphy.

Ricoh’s Herold points to consumables as the source of some pain points. “One of the biggest challenges the industry continues to face is determining the best paper for customers to achieve a high-quality output appearance at a reasonable cost,” said Herold. “As the RICOH Pro VC60000 and its enhanced paper handling capabilities demonstrate, Ricoh is committed to investing in new inks and other features—like coating techniques—that help our customers maximize their print quality, while staying on budget.”

A Look Ahead

Inkjet’s Age also asked these experts to detail some of the new products that were on the horizon—especially as we look ahead to this year’s commercial print trade shows and start the countdown to drupa 2016.

“We are proud to install our first cut sheet inkjet devices utilizing Niagara technology by April,” said Poulin. “That will be closely followed by commercial rollout beginning in July. We consider this game changing technology and are positioned well to enter new markets through this emerging technology.”

At the end of February, Xerox unveiled the new Xerox Rialto 900 which, according to Graupman, “changes the playing field with lower print volume thresholds allowing more providers to acquire inkjet technology and reap individual and industry-wide benefits.”

According to Herold, “Ricoh has demonstrated its commitment to the marketplace through continuous innovation and investment protection for customers. This will continue going into the future as well. Ricoh will continue to provide excellent inkjet solutions that are accessible to a wide variety of customers, and are supported and implemented by the best professionals in the industry.”

“Kodak will continue to unleash the speed of the Kodak Stream inkjet technology, the core of the Prosper writing system. You can expect to see a new B&W inkjet press that will leap-frog the competition in speed. And in our ongoing effort to lower the total cost of print and expand the applications printed on Prosper presses, you can also expect to see an offline paper coating system, based on Kodak’s proven IOS technology,” said Will Mansfield, Worldwide Director of Sales and Marketing for Inkjet Presses for Eastman Kodak Company.

“The market should expect new innovations from HP that accelerate the transfer of analog pages to inkjet,” said Murphy. “New advancements will enable greater productivity, media breadth and application diversity that will drive inkjet adoption from niche to the mainstream. Upgradability, customer success and technology leadership will continue as foundational pillars of these advancements.”

HP T260 Mono Inkjet Web Press: Released May 2014

The HP T260 Mono Inkjet Web Press is designed specifically to help publishers increase speed-to-market and profitably print high-quality black and white books in both large and small quantities. With unprecedented productivity, the HP T260 Mono Inkjet Web Press delivers four-up 6 x 9 pages or three-up A4 pages at fast mono speeds of up to 800 feet (244 m) per minute, and robust performance with a high duty cycle of up to 111 million mono landscape letter-sized pages per month. The HP Priming Solution enables HP Inkjet Web Press users to print on a broader range of media, including standard offset coated media that is not typically compatible with production inkjet technology.

Prosper 6000 Press: Released June 2014

There are two models of the Prosper 6000 Press:

- The Prosper 6000P Press is well suited for producing a range of high page-count / medium-to-low ink coverage documents, including color or monochrome trade books, marketing and law books, text and workbooks, direct mail, letter solicitations, inserts, newspapers, catalogs and magazines.

- The Prosper 6000C Press is ideal for the demands of commercial print operations that produce direct mailers, inserts, catalogs, books and newspapers with very high ink coverage.

The Prosper 6000 Press is able to consistently deliver print quality that’s comparable to offset—approaching 200 lpi on a range of uncoated, coated, glossy and silk papers—with zero compromise on productivity.

Kodak’s Intelligent Print System (IPS) is an advanced press management process that monitors and evaluates system operation to ensure color quality and highly efficient throughput. It continuously measures paper transport efficiency, imaging performance, and any registration variations. Based on real-time feedback it calculates and makes adjustments to ensure uninterrupted high-volume production.

From in-feed to take-up, the Kodak PROSPER 6000 features a robust and reliable design optimized for productivity, faster system start-up, and the ability to handle the widest range of papers. It’s an output workhorse, producing up to 90 million top quality pages per month, on substrates from groundwood to glossy.

With a combination of productivity, the low-cost consumables, and reliability, the PROSPER 6000 press produces saleable prints at a low cost per page; approaching $0.005/A4 in color consumable costs. Other factors that contribute to cost savings – and profitability – are longer inkjet head life, greater operational uptime, and press settings to reduce job set-up and make-ready time.

Inkjet Corrugated Packaging Solution: Released August 2014

Based on the HP T400 Simplex Color Inkjet Web Press, HP High-speed Inkjet Corrugated Packaging Solution enables high-volume packaging converters to realize the benefits of digital production. The press allows converters to transition high-value jobs from analog litho-lamination and flexographic processes to digital to take advantage of short and medium runs, versioning and reduced costs. This switch helps meet customer demand for fast time to market, micro-segmentation, increased production flexibility and a reduced environmental footprint.

CiPress 325/500 MICR: Released September 2014

The CiPress 325/500 MICR provides customers with the flexibility to print full color MICR applications, migrating from monochrome cut sheet or CF devices and eliminating preprinted forms. The fifth channel means only the MICR content on the page is printed with MICR ink. Its field upgradeable to existing CiPress systems and at 500 feet per minute, it one of the fastest MICR solutions in the market today.

Impika eVolution: Released September 2014

Making its North American debut at Graph Expo, the Xerox Impika eVolution is flexible enough to handle both plain papers and high-quality, inkjet-treated stocks. The drop-on-demand piezoelectric production inkjet device runs at speeds up to 832-feet-per-minute/3,628 pages-per-minute. It offers roll-fed, continuous-feed capabilities with a 20-inch web width.

Patented variable speed technology—made possible by a frame architecture suited for two to four print heads—maintains maximum image quality when increasing or decreasing rates. This scalability doubles the productivity on a single platform and delivers more usable, sellable prints day after day.

For added productivity and automation, FreeFlow Digital Workflow Collection can be integrated into Impika devices and supports all major data streams including PDF, PS, and IPDS.

Adjustable printing quality – evolves to meet the specific requirements of each application with three print resolutions: 600 x 360, 600 x 600 and 600 x 1200 dpi. Exceptional print quality is achieved with variable drop size technology.

In February 2015, Xerox introduced the Impika Evolution’s VHQ (Very High Quality) mode, which uses multi-bit drop levels to enhance image quality on plain and inkjet treated papers increasing the smoothness, detail and visual resolution of images. VHQ is unique in that different drop sizes are ejected from different nozzles enabling more precise drop placement and highly accurate registration.

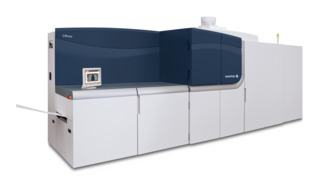

Océ ImageStream 3500: Released September 2014

Three technologies have come together to allow the Océ ImageStream 3500 to print on standard offset coated papers. New high fidelity pigment ink set with properties optimized to a papers surface energy along with an increased optical density through a more efficient use of pigments. New generation of print heads from Kyocera with a native resolution of 1200 dpi with multilevel droplet size which produces an excellent output quality. New drying concept optimizes the drying process. All three of these innovative technologies opens the door to print on standard offset papers without the need for primer coatings or bonding agents.

Without the need of primer or bonding agents we have opened the spectrum of available papers which includes a range of light weight papers and offset coated stocks. Print providers are no longer restricted to a specific type of paper and can use the same papers across various manufacturing methods (inkjet or offset). Without the need of an inkjet optimized or inkjet treated paper a print provider can realize a paper cost reduction of up to half.

The Océ ImageStream from Canon Solutions America is capable of producing high quality prints at a native resolution of 1200 x 1200 dpi. With Océ Multilevel technology the image quality has a perceived resolution greater than 1200 dpi resulting in smoother color gradations.

The device is built on a paper transport capable of running a 30-inch wide web with an image width of 29.5”. The printer can run at speeds of 525 ft./min or the equivalent of 19,200 B2 sheets per hour. With floor space at a premium the Océ ImageStream 3500 comes in with a foot print 10 – 50 percent smaller than competitors in this category of inkjet devices. The ImageStream is environmentally friendly with a low energy consumption. Its’ competitors need to run massive dryers in an attempt to dry the ink on coated papers even with bonding agents and primers, which all equate to a higher running cost.

RICOH Pro VC60000: Released September 2014

The RICOH Pro VC60000 offers near-offset quality (1200x1200 dpi), on a variety of papers, including coated offset paper. It also offers an industry-first optional protective coat unit, which adds a special coat to output to protect it from the finishing and delivery process.

It is capable of producing more than 100,000 letter images per hour, provides a function-rich total solution for customers new to digital color, and for those already using digital print but wanting to consolidate and streamline their operations.

The drop-on-demand stainless steel piezo printheads adjust ink drop size dynamically for every pixel, enabling users to use ink efficiently for optimal print quality. Additionally, Ricoh’s high-density, quick-drying pigment ink helps prevent smearing, bleeding or blotches.

The RICOH Pro VC60000 offers a number of finishing options that help users take advantage of different types of media, and thus take advantage of the opportunities of high value applications such as on-demand book printing, direct marketing and more, where media is a key factor. The optional undercoater hardware enables users to take advantage of a wider variety of papers (including offset coated stock), beyond stock that is only designed for inkjet. The undercoat bonds to the paper and controls dot gain and beading. The optional protective coat unit is an industry first that enables users to add a special coat to their output to protect it from the finishing and delivery process. The optional extended dryer’s dry heat enables users to adjust the drying time for output, depending on paper and ink coverage

The DFE, Ricoh’s TotalFlow Print Server R600, provides production printing capabilities and is tightly integrated with Ricoh’s software, solutions, and strategic partner offerings, giving customers several options to increase their efficiency and productivity. These include RICOH ProcessDirector and RICOH TotalFlow BatchBuilder workflow software, RICOH TotalFlow Path, Avanti’s Print MIS technology and PTI Marketing Technologies web to print solutions.

Truepress Jet520HD: Released October 2014

The Truepress Jet520HD from Screen USA introduced a completely new design, including paper transport, drying techniques, printheads, screening and wide-gamut inks that have never before been used in continuous-feed inkjet.

With a maximum true resolution of 1,200 dpi x 1,200 dpi and using a grayscale head to provide apparent resolution of 2,400 dpi x 2,400 dpi, the Truepress Jet520HD allows users to produce high-end publication and commercial work and direct mail programs. This increase in print quality allows the Truepress Jet520HD to clearly image detail smaller than 1/10th of a point, allowing offset/digital hybrid and toner-based work to move to lower-cost, continuous-feed full-color inkjet.

High-density pigments for each color give more vibrant hues, expanded process color gamut and smoother solid area ink coverage, achieving densities extremely close to offset across all colors. And the newly designed transport not only offers a near-automatic web threading procedure but also allows these inks to dry on both coated and uncoated stocks from 40 gsm to 250 gsm.

An important dimension of the Truepress Jet520HD is the flexible range of output resolutions, speeds and print densities — 1,200 dpi x 1,200 dpi, 1,200 dpi x 600 dpi and 600 dpi x 600 dpi — coupled with operator controls that will offer production value to match the requirements of the job. And within the press is a new evolution of Screen’s proven scanning technology, capable of up to 1,200 dpi analysis of printhead health to optimize print quality at all of these speeds.

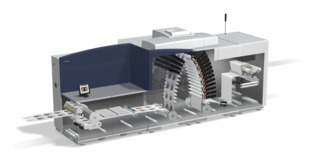

Rialto 900 Inkjet Press: Released February 2015

The new Xerox Rialto 900 Inkjet Press, a roll-to-cut-sheet device, overcomes traditional inkjet barriers by extending the benefits of high-speed production at lower print volumes. This narrow web (9.84 inches / 250 mm) press is ideal for shops of all sizes to add redundancy and/or to migrate jobs from legacy cut sheet or high end continuous feed devices.

The press prints at 1000 x 1000 dpi visual resolution, handles up to five million pages per month, and offers the speed and image quality required to take on full-color, personalized direct-mail, statements, and books. In addition to its small footprint, which includes the press tower (11.9 x 5.1 feet or 3.58 x 1.55 meters), the device’s all-in-one design means the front-end controller, paper roll and finishing components are housed within the machine – a space saver and service convenience.

Automating and simplifying the production of direct mail, transpromo and transactional applications happens seamlessly with workflow offerings, including XMPie’s PersonalEffect, Xerox’s FreeFlow Core and VI Suite and solutions from GMC and Solimar – all driving the press at rated speed for maximum productivity.