Digital Printing Shines for British Book Publisher

Established in 1978 by Rowley Atterbury, U.K. firm Hurtwood Press is dedicated to making distinctive books for niche markets.

Established in 1978 by Rowley Atterbury, U.K. firm Hurtwood Press is dedicated to making distinctive books for niche markets. Today, partners Jo Hilton and Francis Atterbury are a team with more than 30 years’ experience of book production and high quality printing.

“We make books,” Atterbury begins, setting out the nature of Hurtwood Press. “Technically, we’re a publisher, but we manage more book projects for other publishers than we publish of our own.”

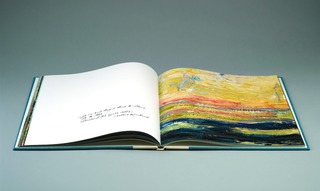

Hurtwood Press’s books are mainly fine art and books by photographers. There are also exhibition catalogues and books that support those exhibitions as well as fine editions for specialist publishers. Production runs can vary from 20 to over 10,000.

“We work closely with customers, artists, publishers and book designers to understand what they want," Atterbury says. "Once we understand the vision of the book, then we can think about the best technology to achieve the desired result.”

Importance of digital

Digital printing and proofing are important to the work of Hurtwood Press.

“I use HP Indigo presses for almost all my proofs now,” Atterbury says. “There are several advantages. First, they can be printed on the final substrate and presented to clients in very nearly the finished form. Secondly, proofing on an HP Indigo press can be considerably less expensive than other methods, and thirdly, clients tend to request fewer changes when they can see the proof cut and bound as pages. It’s as though they are considering the book as a whole and not thinking about giving a critique on individual images or aspects.”

Hurtwood Press has used HP Indigo presses for selected books since 2007 when Atterbury used it for a short-run book for a private collector. Atterbury admits he “was staggered how good the result was” and impressed that it was achieved by a normal CMYK set."

He adds, “HP Indigo presses can more easily achieve a wider color gamut than offset.” To achieve similar results with offset could take three proofs, 4,000 sheets and several touch plates. With digital, you might get it in two attempts.”

It’s not only color reproduction on HP Indigo presses that makes Atterbury prefer them for some work.

Better than offset

“HP Indigo presses can give better results on uncoated paper than offset,” he says. “The blacks lie flat, whereas using other digital presses, the image can look shiny, and create too much gloss in the shadows. On an Indigo print the ink sits flatter; it’s possible to take in the whole image at once, and not be distracted by the way the toner reflects in different area.”

Atterbury uses a number of different HP Indigo print service providers for his books. “Like anything else, printers have certain areas where they are confident and excel,” he says. “Then there are those who are more willing – and more successful – in pushing the technology to achieve a result.”

“While digital does enable you to print smaller runs, it can do much more when seen in the context of quality printing and publishing,” Atterbury explains. “While we are primarily a fine art publisher and print consultancy, we do other things, too. For example, we’ve done a local history book and we’re producing the yearbook for the local school. While it’s a relatively short run, that’s not really the point. The real point is to produce something that when, in thirty or forty years’ time, the former student brings the yearbook down from the loft, it doesn’t fall to pieces on opening and still looks fresh.

“A lot of printers feel they should explain how they print their customers’ work. I don’t: my concern is to find the best method to produce the job, and that decision takes a lot of thought,” Atterbury notes.