Labels Are Hot! Embellishment is Hotter!

Are you a label service provider? Labels are big business. From simple stick-on tracking labels with barcodes to complex, textured labels that make products dazzling and touchable, the label printing industry is growing across all technologies in the ecosystem. Flexo, hybrid and pure digital printing have expanded their scopes and evolved their value propositions as the global demand for short-run, variable labels has exploded.

If you are experienced with offset and flexo, the opportunities to expand with hybrid or pure digital options continue to grow. Pure digital printers have opportunities to expand with digital label printing solutions that become more interesting in each innovation cycle. To understand the opportunity for your company, start by understanding your options.

Flexo

Flexo label printing is the traditional analog technology that uses flexible polymer plates to transfer ink to label stock at high speed. Like all analog presses, each plate carries a color, with some machines supporting eight, 10 or 12 colors.

What makes a flexo label press special is the system that surrounds the printing. Flexo systems for label printing may be configured to add adhesives, laminates and foil, but remember, this is only the printing part of the process. These systems also handle the converting of the rolls into the final product with die-cutting and waste removal.

Digital

Digital label printing is what you would expect. Toner and inkjet solutions on the market are at a variety of price points, capacities and capability sets. Everything from desktop devices common in warehousing to truck-size devices with all the capabilities of their flexo cousins have been on the market long enough to earn the reputation of being a mature technology. Innovations in inkjet printing of labels and a growing range of inkjet-ready label stocks are expanding the types of label work moving to digital printing, as well.

Hybrid

Hybrid label printing grew out of early efforts to provide variable content in a traditional flexo environment. In the early versions, innovative printers would hang digital technology on their flexo presses or incorporate flexo stations into their digital print system to build solutions capable of adding variable content inline during the print run. The goal was to bring the rich capabilities of flexo and the variable capabilities of digital together to create new, higher-value labels. These systems have been commercialized and are in wide use today because they address a need for speed, expansive print options and variable. For some companies, hybrid solutions will always be the best fit.

There is business for all these technologies in the future of label printing, so how does an LSP differentiate themselves in the market? The printing technology alone will not be enough. That brings us to the opportunities that shape the future.

At the most recent Label Expo in Brussels and at the inaugural Printing United in Dallas in the autumn of 2019, innovations were on display for every part of the label printing process. If you are an LSP, no matter what technology you use today, you should consider one or more of these options.

- Variable Embellishing

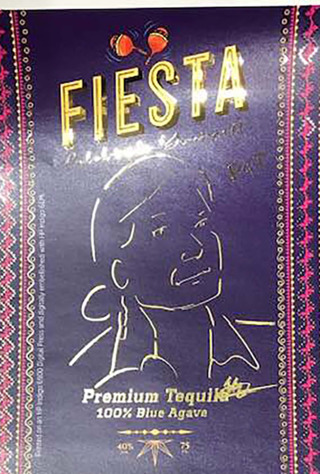

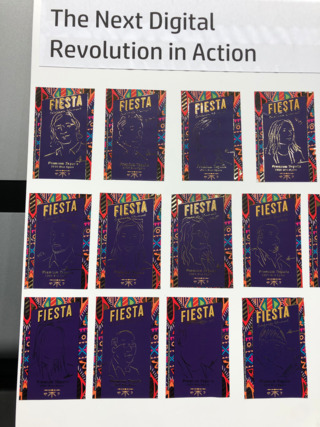

Embellishing labels with foil and varnish is not new, but one of the most personal demonstrations using embellishing at LabelExpo 2019 was in the HP stand where they had an artist make a sketch, uploaded it to SmartStream Designer, and then print a set of labels with the sketch as part of a label. This was an important demonstration because it involved the innovations included in HP’s ElectroInk Silver to produce a range of metallic colors.

Two paths to digital embellishment were operating on the stand: HP Indigo GEM was used to place the foil, spot varnish and other embellishments in a single pass, and for print-over-foil, the demonstration featured the HP Indigo 6900 Digital Press with the KURZ DM-Jetliner inline. The Kurz stand had a duplicate of the production line running a different, but also variable, demo.

Why this is important: In the competitive world of label printing, differentiation will be an essential element of business growth. Whether you use HP’s solutions from MGI and Konica Minolta, flexo solutions or other providers, the goal is to add capabilities to provide memorable visual appeal to the products. The opportunities exist for short-run, variable and long-run static labels.

What’s the catch? Selling these solutions takes some rethinking on the part of the sales team. These aren’t “take an order” sales. These sales typically require a bit of art, a bit of science and a bit of theatre to help the buyers understand what they can gain. Prepare in advance so your sales team is ready to sell what you can do! - Industrial Embellishing

This is a growing area that you must investigate. Industrial Embellishing covers the growing area of Near Field Communications (NFC), RFID labels, labels that include audio accessibility from a barcode, augmented reality, labels that change colors due to heat or cold, and labels imbued with GPS technology to turn labels into tracking beacons. And don’t forget the anti-counterfeiting solutions.

Many of these solutions were on display at LabelExpo last autumn, and in upcoming shows we are likely to see more solutions. Some of these solutions rely on specific label stocks, but over time expect to see more of the technology printed inline with the content. If you serve industrial markets, this is a good time to start researching the technology.

Why this is important: Differentiation is the story here, but it goes beyond differentiation. Laying in the capabilities to create unique customer experiences using these technologies should attract brands with an eye for innovation. Imagine a label that opens an AR experience that can change over time. Inside the retailer it might explain the product benefits, but outside of the store the experience may change to instructions for use. All these industrial embellishments have the potential to change how customers think about the labels they buy.

What’s the catch? Getting salespeople to sell the innovation and opportunity is a hurdle. There are many ways to jump the hurdle, but it is important to remember that innovations can be intimidating. Help your sales team prepare by taking them on the journey as technology is reviewed and be prepared to help them understand the talk tracks to use with current and prospective customers.

If you are an LSP, the future has amazing possibilities. Keep your eye on offerings from your current vendors, but also from the new crop of solutions providers emerging with innovations that can help you create solutions for your customers that are sticky.